Date: 4 May 2012

Additionally customers have recognized they can rely upon the efficiency of the support services from the entire team. Customers have stated that purchasing decisions have been based upon the reliability and technical advantages offered by companies within The Glass Machinery Company portfolio along with its commitment to quality guarantees and client satisfaction. Meccanica Cambi is one such company which for over 30 years has specialized in the production of machines for the flat glass industry. Based in Italy the company is dedicated to constant evaluation of the market and its needs, ensuring that the technology remains at the forefront of the industry.

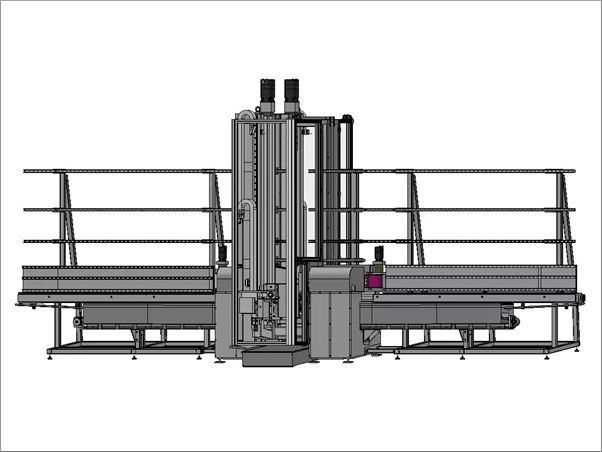

The range includes: edging and bevelling machines for shaped, oval and circular glass sheets; horizontal and vertical glass drilling machines with two opposed drills; automatic corners grinding machines (without templates); machines for diamond wheel grinding. For manufacturers the automatic products in the Meccanica Cambi range greatly assist in accelerating production methods. For example the Verticam C/130 which vertically drills glass sheets has a variety of options to suit all sized manufacturers requirements. Manufacturing methods are simplified with the horizontal movement on the X axis being controlled by belts with brushless motors while the double conveyor moves the glass along at both the inlet and outlet positions. Additional roller modules with idle wheels as well as other tools can be easily integrated into existing production methods. Glass drilling programs have a tank and pump to recycle water efficiently and are numerically controlled with the ability to import .dxf files if required. Another popular glass drilling machine within the range is the C1100 which has recently been installed at a number of sites in the UK.

This versatile machine has been designed with opposed drilling heads and is available in either a semi automatic or fully automatic options. The semi-automatic version has an automatic lower drilling head while the upper head is operated manually with a lever. The automated option comes with automatic drilling heads that are adjusted according to the thickness of the glass that can be up to a maximum of 30 mm thick. With an automatic clamping capability as well as the ability to automatically eject the glass cores the C1100 system improves the drilling process considerably, providing 8 variable speeds and a throat depth of 1100 mm which enables manufacturers to drill glass sheets up to 2.20 metres thick. Both the automatic and semi-automatic versions of the C1100 can easily be integrated into existing production lines and will help to accelerate production times. The exceptional support services and reputation of The Glass Machinery Company is leading many industry leaders to realize the their business potential by installing equipment from The Glass Machinery Company portfolio giving them a clear advantage in the glass processing arena. For more information please call 01630 638555 or visit the website: www.theglassmachinerycompany.co.uk.

Add new comment