Date: 10 July 2019

Pilkington United Kingdom Ltd, part of the NSG Group, has invested more than £3 million in new technology to increase its capacity to manufacture Pilkington Planar™, and meet growing market demand for its internationally sold structural glazing system.

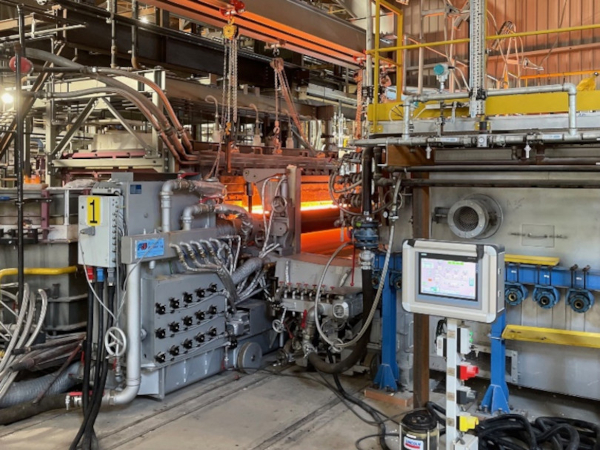

The glass manufacturer has invested in a new state of the art toughening furnace, an increased capability heat soak oven, and a glass measuring device. Each will be used as part of the manufacturing process for its Pilkington Planar™ structural glazing system and associated products.

The new toughening furnace, due to be operational by August, will be located at the Pilkington Architectural site in St Helens. It’s expected to help the company manufacture increased volumes of the Pilkington Planar™ System.

The investment also increases the size capability of the toughening furnace and heat soak oven to 6000 mm x 3000 mm. Meanwhile, the newly developed glass measuring device will enhance the manufacturer’s quality control systems and processes for the benefit of customer and end-clients.

Structural glazing systems are used in a variety of applications including glass atriums, facades and other specialist uses. The company has developed, designed and manufactured structural glazing systems and products in the UK for more than 60 years, serving both domestic clients and a growing number of export customers across the globe.

Phil Savage, head of sales – UK processing at Pilkington United Kingdom Limited, said: “We’re at the forefront of providing innovative products into the commercial construction sector, especially in the area of structural glazing, where this type of glass and glazing system is increasingly specified and incorporated in high-performance buildings.

“The challenge of delivering projects that achieve both high functionality and excellent aesthetical appeal has been more ubiquitous in building design over the last five years. This is where structural glazing systems are an established solution, helping specifiers to meet both requirements.

“This investment helps us to serve this growing demand with enhanced efficiency and superior quality products, helping our customers to create a built environment fit for the future.”

UK-manufactured Pilkington Planar™ glass has been recently installed in international projects including the Al-farwania Court Complex and Hawally Courts Complex both in Kuwait; the 601 Massachusetts Avenue development in Washington DC; the American Dream Mall in New Jersey; and the Valley Fair Mall, California.

For more information on Pilkington structural glazing products, click here.

600450

600450

Add new comment