Date: 23 April 2013

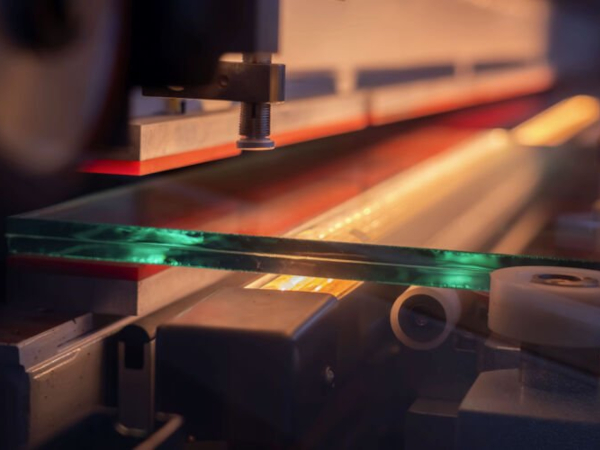

The order comprises the refurbishment and modernisation of a 20-section blowing machine, a 16-section press and a 20-section stem polishing machine at the Kavalierglass facility.In future, the blowing machine will be controlled by a FBC system (Futronic Blow machine Control system), which unites the machine control equipment and the synchronous drive in one system. A FPC controller (Futronic Press machine Control system), a modular control and drive system for up to 20 sections, will oversee the press.

futronic's previous experience of developing, designing and manufacturing a complete control system for two stemware production lines on behalf of Forma Glas - from glass cutting at the feeder to the conveyor to the annealing lehr - will come in very handy for this latest project. For the first time, futronic will also adapt one of its controls to the needs of an automatic cracking-off, grinding and polishing machine (ASPA).

Alexander Körner, the futronic sales engineer responsible for the project, is confident that the challenge can be met: "Both the hardware and the software of our control systems can be flexibly tailored to a broad set of requirements in the glass production process. That's something we've already demonstrated effectively in a number of similar projects." The completely overhauled line with the new futronic controls is expected to go productive in the Czech capital at the end of July.

Add new comment