Date: 12 April 2016

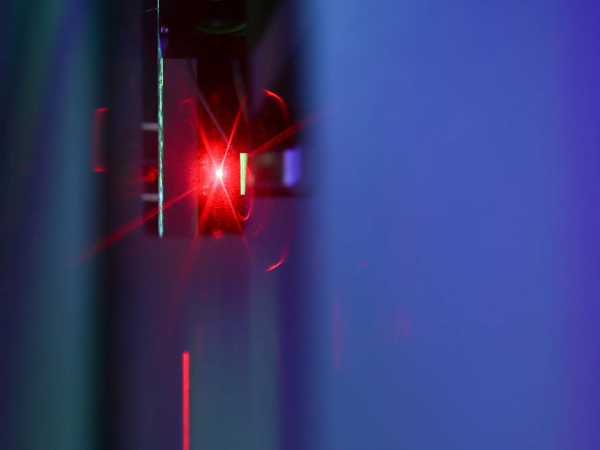

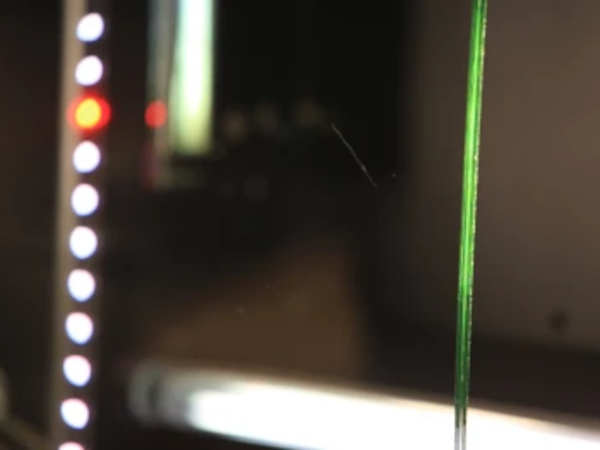

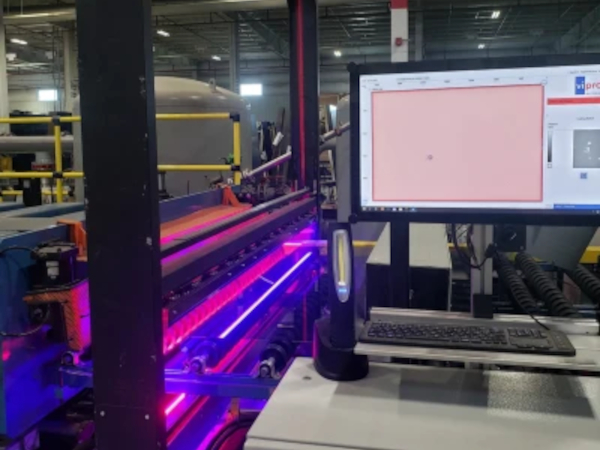

In recent years, the company has introduced a series of important hardware and software refinements to create its latest EVOLUTION 12 and EVOLUTION 5 HD machines, in addition to several standalone equipment innovations that address the precise requirements of luxury, pharmaceutical and cosmetic glassware producers etc. Since launching the HD range, more than 150 machines have been installed.

Each of these innovations has been developed in close co-operation with key customers and has been widely adopted by glassmakers throughout the world. Now, the company’s dedicated team of mechanical, optics, process and software engineers has been expanded to create the next generation of EVOLUTION machines. With more than 15% of turnover invested in R&D every year, the team’s goal is to increase the precision of hollow glass inspection and the detection of defects in order to maximize the productivity of the glass container manufacturing process. In addition, the team is developing specialist solutions for quality-conscious glass tableware manufacturers.

“We are focusing IRIS engineers on finding solutions to new customer challenges, as well as maximizing service levels for glassworks throughout the world” said Jean-Luc Logel, Managing Director. “This includes the creation of a technical after-sales operation in Sao Paulo, Brazil to provide installation services, customer training and online assistance/service for a growing portfolio of clients in Latin America.”

The IRIS team will be present at every key international glass industry event throughout 2016, including China Glass (Shanghai), Glassman Middle East (Abu Dhabi) and Mir Stekla (Moscow), culminating in the company’s participation at glasstec in Düsseldorf this September. The team looks forward to discussing the company’s latest development priorities with customers and other glass industry partners at these and other events. Further information about the turnkey glass container inspection solutions available from IRIS Inspection machines is available from www.iris-im.com.

600450

600450

Add new comment