Date: 5 October 2016

In your glass cutting department, wouldn’t it be nice if one loading system could do all the following?

- Bring an entire rack of glass to the loader quicker than present systems bring a single stock sheet.

- While the cutter is working on the present rack, bring the next rack to the opposite side so not a single second is wasted changing glass types. Of course, once the cutter makes the stock change, put the used glass back into inventory and get the next rack ready, whether it is needed in five minutes or five hours. DON’T EVER MAKE THE VERY EXPENSIVE CUTTING SYSTEM WAIT.

- Have the same loading system feed multiple cutting systems from the same inventory. It’s silly to have a separate loading system for each cutter. Well, if you waste all that effort loading a lite at a time, instead of an entire rack, I guess you are stuck with that.

- Be capable of dense storage so no space is lost, even if packs of glass require only 16 inches of floor space but rack glass may require 30 inches. Deal with it.

- Be capable of stocking any and all sizes ranging from 60 X 72 to 130 X 204.

- Be capable of stocking the thicknesses ranging from 2.0mm to 19mm.

- Be capable of delivering to either a free fall station or a vacuum loading station for your larger or heavy glass.

- It (almost!) goes without saying that the quality has to be the best, space requirements the smallest and price has to be affordable.

OptiLoad does it today! Not on paper…it’s different, it’s simple and it works.

We are delivering OptiLoad systems now. They are customized and enable you to manage more raw glass SKUs in less space while increasing yields, decreasing labor costs and improving safetly—all without adding additional glass cutting capacity.

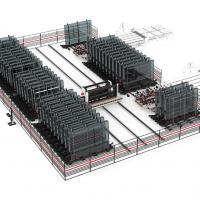

OptiLoad components include our newly designed Dense Storage Shuttle System and Smart Picker. In some cases, your space may better accommodate a Turntable Access System. We combine these designs to fit your existing space!

See for yourself at GlassBuild

Don’t take my word for it. Instead, come to our (Integrated Automation Systems) booth number 2104 at GlassBuild in Las Vegas to see for yourself.

Why do we create breakthrough solutions like OptiLoad?

We offer more than 20 innovative solutions for glass handling, gas filling and quality. We create processes and machines that do things needed in the market but not replicate what is already available.

We can make better but our goal is to create unique breakthrough solutions.

We strongly believe engineering a better system starts by taking a look at what our customers need yet others are telling them “that’s not possible.” We then challenge ourselves to prove them wrong.

If you would like more information on OptiLoad (or OptiGas, FastGas, ThermalCheck, OptiClose or any of our solutions) before the show, contact Ryan McHugh at 330.954.3070 or ryan@optigas.com for an in-depth glass handling discussion along with a layout and proposal on just how OptiLoad can transform glass handling in your present space.

600450

600450

Add new comment