Date: 16 April 2010

Architects have been issued with guidance from RIBA for the first time about incorporating anti-terrorism measures into their designs.

“This advice is very welcome because it will make architects think about the safety of a building’s residents from the outset and, as we now know, terrorism is threat to all of us,” said Denis Wright, managing director of Wrightstyle Limited.

Wrightstyle has been at the forefront in developing glass and glazing systems to mitigate against a whole range of threats, from fire to ballistic and explosive attack, and has recently introduced a system that can withstand even the explosive impact of a lorry bomb.

The Royal Institute of British Architects (RIBA) has issued its advice to improve the way architects and planners think about security. The advice includes a range of measures, including barriers and bollards, landscaping and surveillance, as well as using blast and ballistic resistant glass.

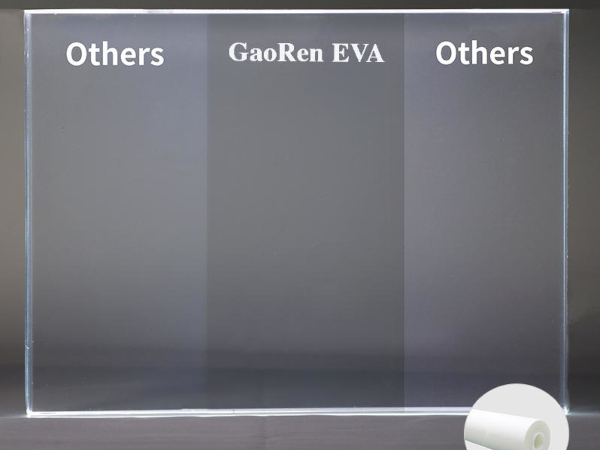

The message that we have been trying to convey to architects is that, if a system such as ours is used for the external glazing, the glazing system will look no different from conventional curtain walling,” said Denis Wright.

The RIBA advice comes in the wake of further recent terrorist atrocities in Moscow and amid continuing uncertainty worldwide.

The importance of blast resistant curtain walling is that the main cause of injury and death from a bomb attack is flying glass. In an attack using explosives in an urban area, between 80-85% of all secondary blast injuries are caused by flying glass.

Wrightstyle’s landmark test, conducted independently at a specialist site in the UK, involved the system being subjected to the equivalent of 500 kilos of TNT, acknowledged as an average-sized lorry bomb.

Although glass and glazing companies have been active for some years in developing safer systems, the attack on the Federal Building in Oklahoma City some fifteen years ago focused research attention.

Amid that carnage, 200 victims suffered from glass injuries and glass fragments were found six miles from the detonation. In New York, on 9/11, 15,500 windows were damaged within a mile of Ground Zero – nearly 9,000 within half that distance. One senior fire officer had to have 47 shards of glass removed from his eyes.

When a bomb detonates, it produces gases at very high temperatures. This in turn leads to a rapid expansion of air and the creation of a shock wave travelling at supersonic speeds. The shock wave lasts only a few milliseconds and is then followed by an equally sudden but longer-lasting drop in pressure. It’s the enormous impact of the shock wave and the subsequent suction that shatters the glass and distorts the framing.

The Wrightstyle system’s strength was achieved through a glazing technique that bonds the glass to the framing support system, so that in an explosion, the components work together to safely absorb the shock of the explosion and retain the glazing elements.

In the independent test at RAF Spadeadam in Northumberland, the simulated lorry bomb attack was immediately followed by a simulated car bomb attack (100 kilos of TNT). The lorry bomb was detonated 75 metres from the test rig, whilst the car bomb was detonated at a distance of 20 metres to produce a higher pressure loading and shock on the façade.

“We may not have yet taken explosives from the hands of terrorists. But for the occupants of those buildings that incorporate the latest blast-resistant steel glazing systems, we have taken away an equally potent weapon: the glass itself,” said Denis Wright.

“We absolutely welcome RIBA’s advice because, from now on, architects must consider the whole range of measures that can be taken to mitigate against terrorist attack, yet still design buildings able to incorporate beautiful glass facades,” he said.

To see a video of the blast test, go to http://www.wrightstyle.co.uk/wba/media/movie/bt_charge.swf

Ends

Picture Caption: The blast test being was conducted at a specialist site in the north of England. If you would like other images, please contact Charlie Laidlaw (below)

Video: If you would like a high-resolution DVD of the blast test, contact Jane Embury (below)

Wrightstyle Limited: The company is a glass and steel system supplier and exports its specialist fire, ballistic and blast systems internationally. www.wrightstyle.co.uk

For further information, contact:

Jane Embury, Wrightstyle

+44 (0) 1380 722 239

jane.embury@wrightstyle.co.uk

Media enquiries to

Charlie Laidlaw

David Gray PR

Charlie.laidlaw@yahoo.co.uk

+44 (0) 1620 844736

(mob) +44 (0) 7890 396518

Notes to Editors:

Factsheet: Glass and Terrorism

The issue of glass as a terrorist weapon was pushed to the top of the security agenda by the attack on the Alfred P Murrah Federal Building in Oklahoma City in 1995, the first time that a major terrorist attack had happened on US soil and which gave rise to an unprecedented level of buildings research. In that attack, 167 people died and 750 were injured.

Based on research carried out by the Walter Reed Army Medical Center following the Oklahoma explosion, “blasts involving explosives inflict severe…injury, mostly as a result of secondary blast effects from glass [and other] debris.”

Most people killed or badly injured in a blast involving high-order explosives (HE) are affected by either primary or secondary blast injuries. Primary HE blast injuries are caused by high-pressure gases from the explosion rapidly expanding to produce a supersonic blast wave. This has devastating effects on human air-filled tissue, particularly the lungs and gastrointestinal tract. Primary blast injuries are generally fatal.

Secondly, HE blast injury caused by flying objects, for example, glass fragments. Secondary blast injuries are much more common than primary blast injuries and are the most usual causes of death in blast victims. The penetrating injuries occur most often in the exposed areas of the body such as the head, neck, and extremities.

The mechanism of injury from blast injuries has been studied since the Balkan Wars in 1914 and continued during and after World Wars I and II. Overall, blast injuries result in mortality ranging between 7.8% in open air to 49% in a confined space. A majority of victims (70%) will sustain soft tissue injury, and traumatic amputations will occur in approximately 11% of cases.

Research from Oklahoma and elsewhere concluded more than one-quarter of glass-related injury victims in buildings occur within 1.5 metres of a wall with glazed windows and nearly one-half of glass-related injury victims are positioned within 3.0 metres of a wall with glazed windows.

Oklahoma focused the attention of the engineering and security communities on two major issues: the prevention of progressive structural collapse (once again a prime focus following 9/11) and the design of blast-resistant glazing. This led the Commission on Engineering & Technical Systems to set up a Blast Mitigation Program to develop methods to protect people inside buildings from terrorist bomb attacks.

The Commission noted that “the focus is on protecting people, not the building or other assets. Two key issues in the program are the primary cause of injuries and death in terrorist bombings; structural collapse, and flying debris, for example, glass.”

The day after the Oklahoma bombing, the US President instructed the Department of Justice to see what conclusions could be drawn in terms of protecting federal buildings. One of the DOJ’s key findings was “to provide for [the] application of shatter-resistant material to protect personnel and citizens from the hazards of flying glass.”

In a later submission to a US Senate Committee on Intelligence, Louis J. Freeh, director of the FBI, said that: “loosely affiliated extremists, motivated by political or religious beliefs, may pose the most urgent threat to the United States. Within this category, Sunni Islamic extremists, such as Osama bin Laden and individuals affiliated with his Al-Qaeda organization, have demonstrated a willingness and capability to carry out attacks resulting in large-scale casualties.”

He was speaking in May 2001, four months before Osama bin Laden proved him right. After those attacks, a clear consensus emerged among urban planners, architects and, not least, the glass and glazing industry. Ways to mitigate against blast hazards posed by terrorism had to be found.

Add new comment