Date: 21 August 2018

In addition to being a sponsor of the 16th annual GlassBuild America trade show in Las Vegas, Nevada September 12-14, GED Integrated Solutions (GED) will be showcasing highly-automated window and glass fabrication equipment at exhibitor booths #2127 and #2327. Among the lineup of equipment is exciting new technology that will change the way window and door fabricators do business.

NEW! WinTrax™ Intelligent Logistics

Leave no window behind with the new WinTrax™ Intelligent Logistics system from GED. Locate and monitor your vinyl window products as they travel inside your manufacturing facility…and beyond!

Reduce material, labor and production costs by tracking products during and after the manufacturing process. Using the WinTrax Intelligent Logistics system and GED Software, an individual can track window components (WIP) and completed windows (finished goods) within residential vinyl window production facilities.

WinTrax will give you the ability to oversee your entire vinyl window production from start to finish, inside and outside your manufacturing facility, with this exciting new technology from GED.

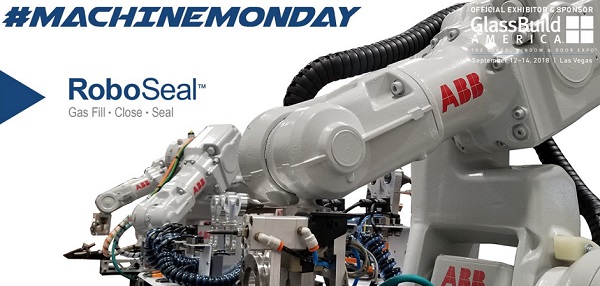

NEW! RoboSeal™ Gas Fill – Close – Seal

A breakthrough in system automation from GED leverages robotic technology for an efficient, higher quality fourth corner gas fill, close and seal for IG units with the new RoboSeal™ system. GED “Robo” products provide users with precision, quality, accuracy and speed of manufacturing. The RoboSeal continues the tradition which began with GED’s revolutionary RoboClean® and RoboFlow™ systems.

The first fully automated, robotic gas fill, close and seal system in the industry, RoboSeal efficiently finishes the assembly process of both double and triple pane Intercept® insulating glass units (IIGU). First, IIGUs that have been oven-pressed and cooled on a vertical conveyor are loaded into the RoboSeal system. IIGUs are then fed into three automated, robotic stations: quick gas fill; close; and seal. The end result is a high quality, consistent, automated fourth corner sealing process.

With the ability to produce six (6) units / minute for double IIGU and three (3) units / minute for triple IIGU, this system handles IIGUs up to 72” by 100” with glass as thick as 6mm. Harness this new GED technology to reduce overall operating and labor costs and maintenance, improve operation safety, and bring consistency to your IG production floor.

NEW! SmartExtruder+™ Sealant and Desiccant Application System

GED’s SmartExtruder Plus™ delivers the exact amount of sealant to the right location with quality control and tracking throughout the production shift. Its precision gear pump eliminates pressure spikes and reduces inconsistencies due to material viscosity, air pressure or ambient temperature. From easy set-up, operation, maintenance and troubleshooting with no downtimes, the extruder provides material savings and consistent high quality, eliminating compensators. Apply sealant and desiccated matrix to within 0.1 g/ft. of desired thickness for improved quality and cost savings, and eliminate fluctuations in the material application from air pressure, material viscosity, or ambient temperature changes.

Here are some of the main features of the SmartExtruder+:

- Encoder based dispensing for starts/stops/skips

- New control platform with a faster scan rate and response time, resulting in a much tighter dispense tolerance for starts/stops/skips.

- The new system does not use a PC based interface, and the user interface HMI is directly coupled with the PLC system.

- Servo position control (width & height motors for sealant and desiccant) is now directly interfaced with the control system.

- Side heads have individual start/stop control with alignment adjustment.

- Improved pneumatic plumbing. A storage reservoir has been added to the pneumatic circuit to improve response time of the dispense valves.

RoboFlow™ with QB Technology

GED’s RoboFlow system brings the best in robotic automation to your window production floor. This vinyl material handling system comes with enhanced “QB technology”—a large material handling robot (the “Quarterback”) coordinates “plays” from GED’s SW-7000 4-point welder to GED’s RoboClean twin-station vinyl corner cleaner—giving you one completely automated system.

The RoboFlow system follows an integrated computerized or bar code generated schedule to orchestrate the flow of multi-stack vinyl onto an x-y conveyor to the QB. The QB, in conjunction with the x-y conveyor, work together to orchestrate movements of the vinyl assemblies into and out of the RoboClean.

The QB turns the product around to clean all four sides of the product, as well as removes it and places it onto an automatic output conveyor that feeds the assembly or glazing lines. The result is a compact vinyl welding and cleaning system that increases quality and throughput, reduces labor and optimizes the efficiency of the operation.

Intercept® 2.5 Spacer Fabrication System

With the Intercept 2.5, industry professionals are assured an ease of transition, operation and maintenance, along with improved productivity. Built to improve speed, it can produce spacers at a rate of up to 85 feet per minute, achieving up to 8 spacers a minute (without muntins).

Industry professionals will recognize the familiar footprint and marvel at the very latest state-of-the-art technologies that easily enables the production of not only Intercept ULTRA Stainless, but also ThinPlate or BlackLine.

Providing superior thermal performance, durability and strength, Intercept 2.5 makes it faster and less expensive to produce than other spacers. Not only does the 2.5 allow for “Just-in-Time” production in the order required without operator errors, it also eliminates internal muntin grid misalignment with precise notching and snap-in muntin clips.

The control system provides significant hardware reduction, making operations and maintenance trouble-free. Patented technology ensures the integrity of the fourth corner identical to first 3 corners, for a consistent product every time.

600450

600450

Add new comment