Date: 21 November 2005

Applied Photonics with headquarters in Scottsdale, Arizona, USA and Jenoptik Automatisierungstechnik in Jena, Germany have signed a cooperation agreement to accelerate the commercialisation of a 'break-through' in laser cutting technology for flat panel display and cell phone manufacturers.Both companies believe that this cooperative effort will help move laser technology into the next generation factories world wide in a more expedious manner. Applied Photonics has developed a patented method for making full laser cuts in attached or 'laminated' display glass of 0.4 to 0.7mm thickness with laser.

The Jenoptik subsidiary contributes in-depth know-how of the engineering and manufacturing to respond to demand of laser machines and laser systems specifically for the flat panel display industry.

Both parties intend to distribute their products world wide with focus on the Asian market.

Under their cooperation, both parties will translate the new laser technology of cutting display glass to production hardware in order to meet the high quality requirements of clean-room production in the display industry.

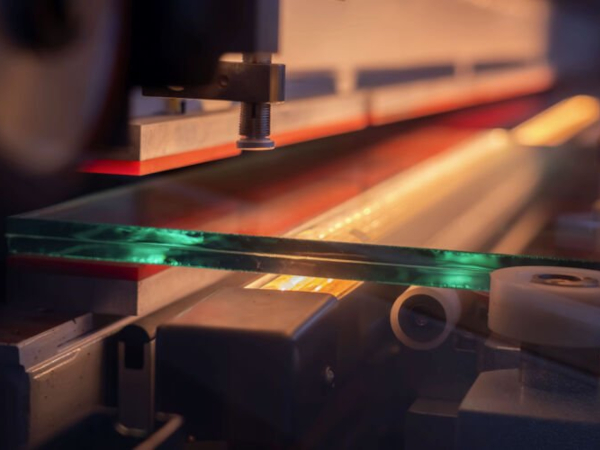

Cutting with laser is faster and provides higher quality The optical and electronic characteristics of glass for flat displays make this material a particular challenge for processing with laser due to the complex interaction of glass and laser energy.

In comparison with conventional methods, such as scribing and mechanical breaking, cutting with laser has several important advantages: Aside from being faster and cleaner, the full cut also produces edges without microcracks which makes the panels stronger and eliminates the need to grind the edges after cutting.

This makes the laser technology not only a cost-saving method for the flat display industry, it also offers higher manufacturing efficiency and improved product quality.

As the trends in industry continue towards larger and thinner displays, this innovative laser cutting technology should become an essential tool for producing high quality displays.

The laser system can make full cuts of single glass or laminated display glass of different sizes.

It is possible to cut the top and bottom panels of a laminated display glass without turning the substrate.

This is possible with two cutting heads in the system.

A pilot system for tests and technology development has been installed at Applied Photonics.

The first production system for customer applications is being set up in the clean room of Jenoptik Automatisierungstechnik .

Flat panel display industry invests in most advanced production equipment Global sales by flat panel manufacturers reached an all-time-high of US$37bn in 2004, after US$23.7bn the year before.

More on the source link...

Add new comment