Date: 27 February 2008

EPIF is one of the largest environmental exhibitions in the Asia region. This will be the fourth such exhibition, with the first three held in Malaysia, Thailand and Singapore, beginning in 2004. The Bridgestone Group continually strives to strengthen its environmental management and minimize its environmental footprint, all aimed at the goal of improving the world in which we all live. At EPIF 2008, Bridgestone will showcase its environmental policy and projects related to environment and conservation.

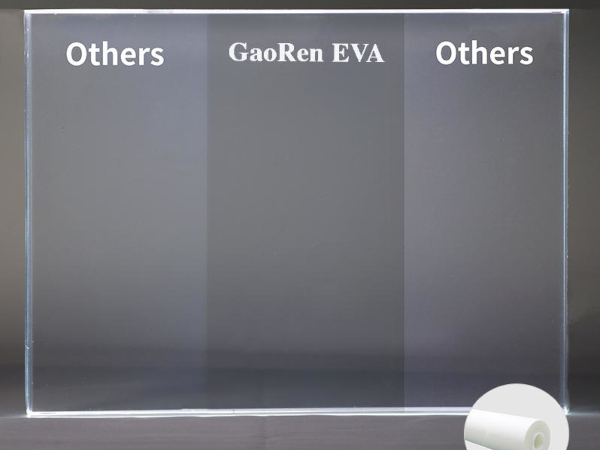

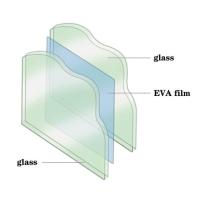

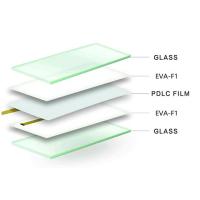

Examples of items that Bridgestone will display will include: the “ECOPIA” tire, an environmental-friendly tire with low rolling resistance, a feature that can contribute to the reduction of CO2 emissions; and efforts to conserve resources, including retreading*1 and runflat technologies. In fields other than tires, Bridgestone will exhibit electronic paper displays that retain images after the electrical power has been turned off, and “EVA (ethylene vinyl acetate) film”*2, which is used as an adhesive for solar modules. Also, Bridgestone's environmental enhancements in its production processes will be displayed, including its “Co-generation system”*3 that is being installed at its tire plants.

<Outline of Exhibition>

- Name: Eco-Products International Fair 2008

- Period: March 1st - 4th, 2008

- Venue: The National Convention Centre, ME TRI-TU LIEM-HA NOI, VIETNAM

(Tel. +84-80-41183)

- Organizers: Asian Productivity Organization (APO)

Directorate for Standards and Quality

Vietnam Productivity Centre

Vietnam Association for Conservation of Nature and Environment

- Web site: http://www.epif2008.vn/Epif2008_Eng/

Notes)

*1. Technology used to remove the worn tire tread, apply new rubber to form new tread and vulcanize it, allowing a commercial tire casing to be reused several times.

*2. EVA film is used as an adhesive to fasten the silicon cell (which converts the sun's rays to electricity) to the glass and surface protection sheet (back sheet), and to protect it.

*3. Cogeneration is a system that simultaneously generates electricity and heat in a single process by utilizing waste heat from combustion process, which eventually leads to the increase of overall energy efficiency.

Add new comment