Date: 26 January 2018

But once they fog up for the first time, the condensation often reveals suction marks that cannot be removed easily.

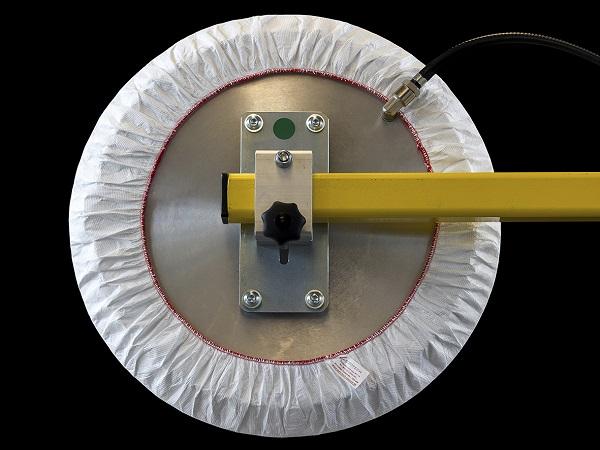

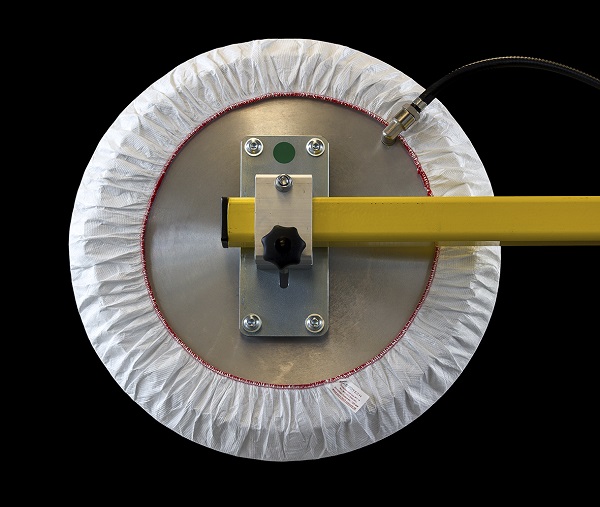

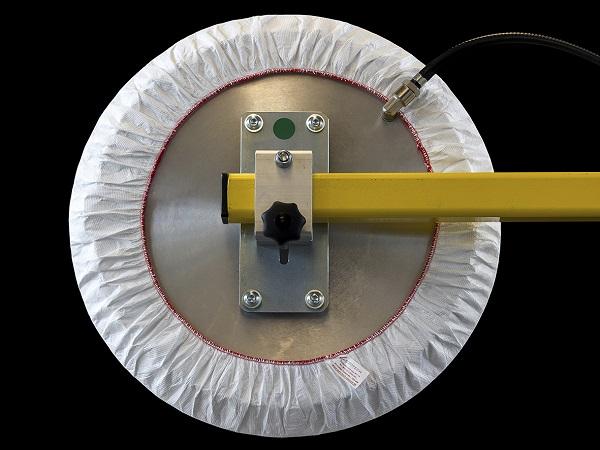

To prevent such marks, the vacuum experts at euroTECH Vertriebs GmbH, headquartered in Geislingen near Balingen, have developed and patented a suction plate cover.

During the production of seals for suction cups, the material is fortified with chemical components and softening agents. These substances fog up or react with the coating when they come into contact with glass.

Suction cups can also cause abrasion damage to glass panes, depending on the sealing lip of the cup and the structure of the supporting surface (grooves, nubs, etc.). If these marks are not removed immediately, they will become visible whenever the panes are exposed to steam.

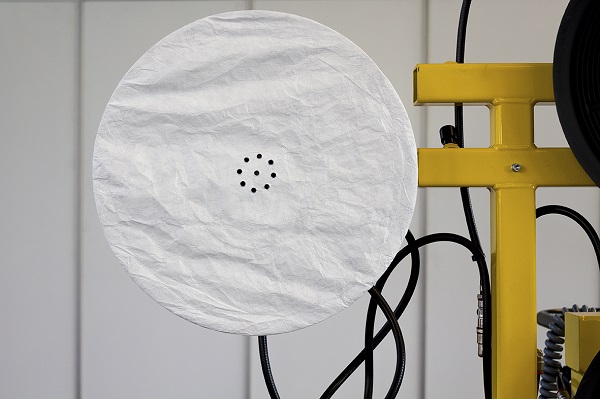

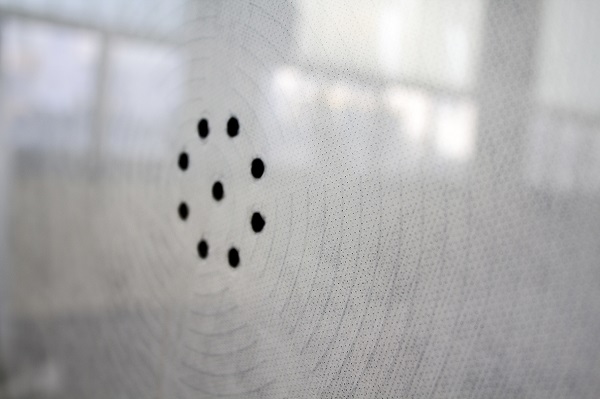

euroTECH developed its MTC suction plate covers to solve this problem and prevent suction marks on the sensitive glass surfaces. The covers are made from an oil-free, silicone-free polyethylene that does not leave any notable marks on glass, provided that the material remains in good condition.

MTC suction plate covers are tear-proof, flexible, breathable and anti-static. They do not produce lint and can be washed and sewn. Their integrated elastic band allows the MTCs to be pulled over the seals and remain in the correct position.

They are tear-proof when wet and dry. The unique fibre structure of the material ensures that this tear-proof quality is maintained even if the suction plate covers are scratched. In addition, the covers are extremely lightweight: they weigh less than half of other materials with a similarly high durability.

When using suction plate covers, note that the friction coefficient decreases. This value can vary depending on the seal geometry.

During horizontal transport, the holding power decreases by approximately two per cent. During vertical transport, around 50 per cent of holding power are lost. This can be offset easily by using larger or additional suction plates.

If a customer requires suction plate covers, euroTECH will take this request into consideration during the project planning and provide suction cups with the correct carrying capacity. The euroTECH product portfolio contains suction cup covers in many different sizes – including ones for oval suction cups.

600450

600450

Add new comment