Date: 30 May 2012

The quality and standards of the company are now well recognized as the partnerships of the leading manufacturers in the portfolio are enduring and reliable.

Customer substantiation has firmly placed the company as a reliable source for all sized manufacturing requirements. Working alongside partners such as Helantec has helped to reinforce the quality standards of The Glass Machinery Company.

Helantec is a long established company that was launched at the end of 1980 providing analysers for the IG market that would offer complete quality control.

Over the years the company, headed up by Gerd Mentel, had witnessed substantial problems occurring in relation to gas insertion and analysis.

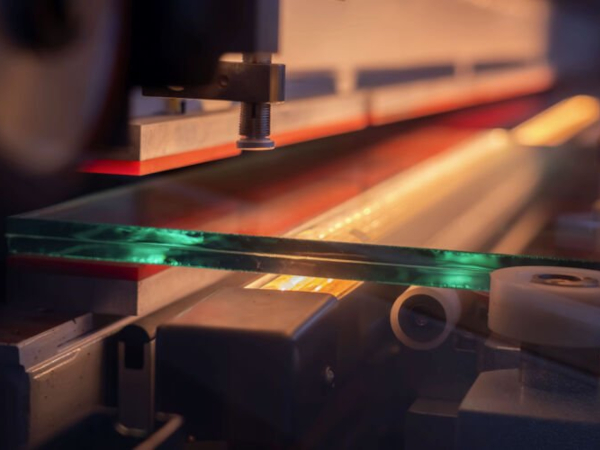

Subsequently the Helantec range was developed. As it is impossible to see, taste or smell gas and its concentration, Helantec developed a range of machines where, via a Communication-Module, it is possible to visualize the gas filling process in real time and document it. Documentation of this kind provides a highly efficient means to gain both production and quality control.

The RAPIDE L 900 model is perhaps the most efficient manual gas filing machine on the market today and represents a new generation of quality awareness and consumer protection. It offers a number of special, unique features which through its speed, greatly reduces production downtime and increases flowthrough.

This is the largest model in the range and being highly efficient provides short filling times with gas over-filling kept to an absolute minimum to guarantee the quality of the finished IG Units.

The Helantec Rapide L 900 is a robust system that is extremely versatile for universal gas filling applications providing the ideal solution for gas filling IG Units in large volumes or with asymmetric construction for example.

Phil Birchall, Managing Director at The Glass Machinery Company comments, ‘As a production management tool the Helantec L 900 can be easily integrated into existing systems providing manufacturers with accurate and reliable quality control methods.

For manufacturers who know how important quality standards are in relation to gas filling, this system provides the ideal solution for large volumes as well as smaller sized batches.

For more information on the Helantec range or other products within The Glass Machinery Company portfolio then please call 01630 638555.

Add new comment