Author: Uwe Risle | Glaston

Source: www.glastory.net

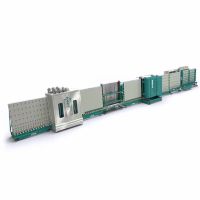

In this third episode of #AskGlaston IG manufacturing series, we discuss the transfer systems of the glass plates.

Glass surface damage must be avoided at all costs during the production of insulating glass units. Even a fine scratch may lead to a rejected IG unit or cost-intensive rework.

That’s why Glaston IG lines are equipped with airfloat conveyors – a contact-free, air-cushioned transport system for both single glass plates and IG units.

The concept is simple but powerful: filtered air is blown through cuts in the conveyor system, creating a soft air cushion that lifts the glass slightly. There is no contact with the rollers, no friction and no scratches.

Each conveyor segment is modular and has its own frequency-controlled drive motor. For higher glass thicknesses, stronger motors are available as an upgrade.

Our standard conveyor speed today is 60 meters per minute – 25% faster than previous systems – but with nearly the same energy consumption. And when the line stops, the blowers switch off automatically to save even more energy.

The system provides:

- Clean transport surfaces

- Easy maintenance

- Modular integration – even with other brands of IG lines

- Pivoting conveyors for flexible layouts

In short – Even for high-speed IG production, Glaston airfloat conveyor technology provides safe, gentle, scratch-free and energy-saving glass transport.

Comments

Fascinating technology! The precision and care taken to prevent scratches on glass plates remind me of the attention to detail seen in high-quality Horse Vitamins — every element matters for peak performance and longevity.