Latest articles

| A Growing Market to Meet Present and Future Challenges

| As a modern society, we’re spending about 90% of our time indoors – at home, in offices or commuting. How is it possible to get access to daylight, when we can’t naturally be outside? By making buildings more transparent.

| As digitalization becomes a strategic discipline in almost all enterprises and industries, the glass processing business is no exception.

| The use of laminated safety glass instead of single glass sheets is especially important in order to mitigate the risks of potential post-breakage behaviour and thus for the fixation of glass fragments in case of damage to the glass.

| Safety standards are constantly rising in all possible areas in which glass is used or installed – which is the reason why lamination is also becoming increasingly important in the glass industry.

| The refurbishment of Hall access involves the complete demolition of existing access for the construction of a new lobby with greater transparency. To get this new image, the architect choose a solution in structural glass, without other structure.

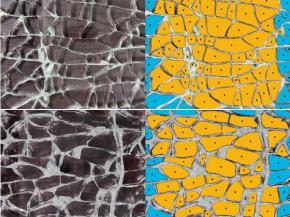

| The fragment count in the standardized fragmentation test in the standard EN 12150-1 is the way to define the safety level of tempered glass and a way to also get an indication about the stress and strength level of the tempered glass.

| This year the special show will address the four focal themes Interactive Façades/Display Glass, Energy and Performance, Structural Glass and New Technologies.

| This article will focus on the edge stability of PVB and ionoplast laminates and address the potential causes of blemishes.

| With the myriad of glass type available now, it is often confusing what to choose in terms of safety, thermal and solar performance and balancing cost with the benefits on offer.

| Minor edge damage during glass handling, a scratch or nick during installation, a design flaw, or a natural imperfection in the glass could all result in spontaneous breakage.

| Laminated safety glass is an excellent choice for building construction—here’s why.

| Laminated safety glass with SentryGlas® ionoplast interlayer has played a key role in enabling the design of an 100-foot-tall glass fin lobby wall on the 150 North Riverside Plaza office building in Chicago, Illinois, USA.

| Stiff PVB is suitable for a much wider range of applications than more traditional PVB interlayers.

| Enhanced strength, edge performance and visual clarity of SentryGlas® interlayer key to The Shanghai Tower’s unique twisting double skin glass façade

| In August 2013, the LiSEC development team started a major project with the mission: redesign of the tempering furnaces in order to save manufacturing costs and at the same time increase the process reliability. Result: the AEROFLAT.

| The lighter bands used in the Cultural Center Väven were created using glazed panels that deployed a specialist Trosifol® PVB interlayer called Diamond White, from Kuraray.

| For more than 80 years, Eastman has been the world’s leading manufacturer of protective interlayer for laminated glass.

| Bullet-resistant glass with SentryGlas® ionoplast interlayer has been installed on the majority of the exterior facades on the new San Francisco Public Safety Building, ensuring maximum protection of the building and its occupants, while also…

| The Flachglas Group employs around 1,100 employees at three sites in Switzerland and three sites in Germany – around 650 of them generate revenues of approx. € 70 million at the Wernberg site (Bavaria).