Others also read

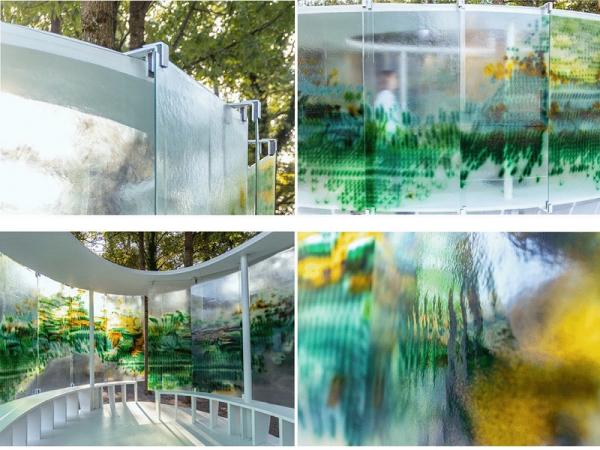

| This research investigates robotically fabricated polychromatic float glass for architectural applications.

| Color Depth is a material-based research project investigating the optical and structural properties of thick glass.

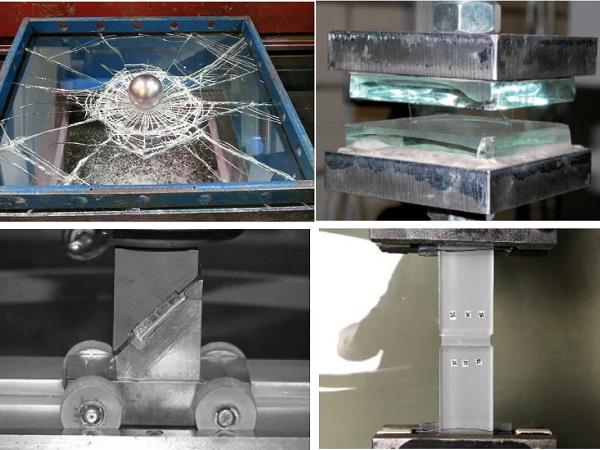

| This paper shows different Pummel classifications that can currently be found on the market. Subsequently, approaches to the automatization and standardization of the execution and especially the evaluation of the Pummel test are shown.

| In the second episode of #AskGlaston Flat Tempering Series, we will talk about the new solution to estimate the stress level in glass – online.

| This first episode is devoted to the white haze phenomenon – one of the most asked about issues in the history of #AskGlaston.

| After seaming, grinding glass edges is another important work step in glass edge processing. The process is primarily used to remove overbreaks and underbreaks at the edges and to process the glass sheets to size.

| In glass edge processing, cutting the glass sheet is directly followed by the seaming process. Fully unprocessed glass edges exhibit overbreaks and underbreaks, conchoidal fractures, as well as micro-cracks along the broken edge.

| In glass edge processing, the requirements for the finished components can vary greatly depending on the location and purpose.

| Today, almost all new devices – from home appliances to production equipment – are connected. Rapid development in consumer electronics has been increasingly moving towards industrial use. In the glass industry, this development is still in its early stages.

| When people talk about the future of production, they can't do so without using the term "smart factory." But what is it? How does a smart factory work? And what does it have to do with OPC UA?

| Few materials in human history have been made for as long or used in as many ways as glass. Ancient peoples molded it and poured it; later cultures discovered how to spin and blow glass into unique, dazzling shapes.

| Glaston is working hard to make tempering furnaces more automated.

| The new LiSEC glass edge deletion machines are equipped with improved sensor technology. This measures with greater precision and therefore guarantees constantly high finishing quality of the glass edges.

| Digitalisation is not only something for start-ups or major enterprises. It applies just as naturally to many skilled trade businesses.

| That’s an excellent question! It really is true that SentryGlass is more difficult to laminate in many aspects than standard PVB. But if we first think of what SentryGlass has been designed for, it is to give structural strength to the laminate.

| It is a very known behavior that the glass fragmentation depends on where you break the glass.

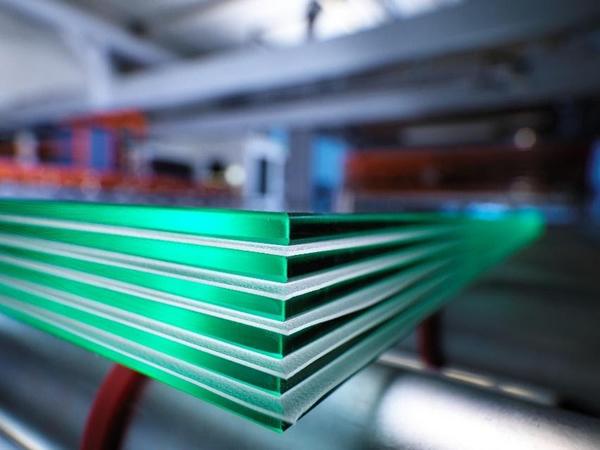

| Safety standards are constantly rising in all possible areas in which glass is used or installed – which is the reason why lamination is also becoming increasingly important in the glass industry.

| During times when the number of suppliers in all industries is steadily increasing and the market is becoming more and more transparent at the same time, the importance of cost-effective production for higher profit margins increases tremendously.

| When we speak about technological progress in mechanical engineering in general terms, conversations often revolve around Artificial Intelligence (AI) and the Industrial Internet of Things (IIoT).

| It is well known that laminated safety glass (LSG) is a material that is specifically processed because of its composition.

Glass off the roll - Thin glass is revolutionising the performance spectrum of glass and glass panes

| Thin glass – as thin as a razor blade or a human hair – is a reliable method to protect smartphone touchscreens, sensitive filters and sensors.

| We’ll help you meet the spec with our knowledge of the glass tempering process.

| sedak GmbH & Co.KG, Germany, operates the largest insulating glass line in the world – about extraordinary glass processing and the role of LiSEC.

| LiSEC is the pioneer in terms of the development and production of production lines for large-scale insulating glasses – incl. interview with Hannes Spiss, facade engineer at Arup, Büro für Bautechnik (office for construction technology)

| Skaala was founded in 1956 as a one-man company. The father of the two current owners, Hannu and Markku Hautanen, was a carpenter and already in those days, he processed glass while repairing doors and windows.

![Tempered Glass Specifications [Video & Transcript] Tempered Glass Specifications [Video & Transcript]](/sites/default/files/styles/6/public/articles/2017/HHH-Tempering.jpg?itok=P7frNEF5)