Article Information

- Digital Object Identifier (DOI): 10.47982/cgc.8.404

- This article is part of the Challenging Glass Conference Proceedings, Volume 8, 2022, Belis, Bos & Louter (Eds.)

- Published by Challenging Glass, on behalf of the author(s), at Stichting OpenAccess Platforms

- This article is licensed under a Creative Commons Attribution 4.0 International License (CC BY 4.0)

- Copyright © 2022 with the author(s)

Authors:

- Dieter Moor

- Victor Rosenberg

- Mikhail Vasiliev

- ClearVue Technologies Ltd., Australia

Abstract

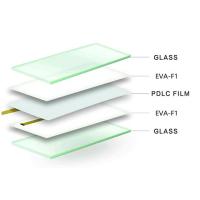

Multiple modern glass and window products based on novel glazing designs, metal-dielectric coatings, and proprietary interlayer types have been developed recently. Advanced windows of today can control properties such as thermal emissivity, heat gain, colour, and transparency. In more recent and more novel glass products, solar energy harvesting through PV integration is also featured. Typically, semitransparent and also highly-transparent PV windows are purpose-designed, to include luminescent materials, special microstructures, and customized electric circuitry.

Recently, significant progress has been demonstrated in building integrated highly-transparent solar windows (VLT up to 70%, with Pmax ~ 30-33 Wp/m2, eg Clearvue PV Solar Windows); these are expected to add momentum towards the development of smart cities. These Clearvue window systems are, at present in 2021, the only type of high-transparency and clear construction materials capable of providing significant energy savings in buildings, simultaneously with renewable energy generation.

The technology has already been deployed and tested in both commercial property applications and in R&D greenhousing. Of special interest is the combination of properties provided by Clearvue solar window products, which includes significant power conversion efficiency (~3.3%), which is achieved in windows of colour rendering index of 99%, simultaneously featuring high PV Yield in multi-oriented building-integrated PV (BIPV) installations.

1. Introduction and Background

In recent years, there has been a significant progress demonstrated in both the R&D and industrialisation of novel BIPV products, materials, and also the window-integrated PV (WIPV) solar window systems. In particular, research progress has been made throughout the last decade in fields such as the development of large-area semi-transparent luminescent solar concentrators (LSC) and functional materials for use in solar windows (Li et al. 2016; Vasiliev et al. 2016; Alghamedi et al. 2014; Reinders et al. 2018; and others). Due to the globally recognised need to effectively decarbonise the built environments, novel types of BIPV and high-transparency solar windows are currently receiving increasing attention. Of special importance is the emergence of newly-commercialised glass-basedhigh-transparency and completely visually-clear BIPV technologies and systems, which have been demonstrated in practical architectural deployment applications.

Even with surging commodity prices increasing manufacturing costs for solar PV, its capacity additions were forecast to grow by 17% in 2021. This will set a new annual record of almost 160 GW in added generation capacity. Solar PV alone accounts for 60% of all renewable capacity additions (IEA Renewables-2021 (2021)). The addition of solar generation capacity in built environments is limited by the available unshaded roof and wall areas, therefore enabling windows to generate electricity simultaneously with providing HVAC and lighting energy savings represents an attractive way forward to achieve substantial and long-term decarbonisation. In buildings with high window-to-wall ratios, installing glazing systems with electricity generation provides perhaps the only viable way to decarbonise, even if window-generated electric power per unit area is (invariably) a fraction of that available from conventional PV.

2. Recent Developments in BIPV and Transparent Window-Integrated PV

Modern BIPV module suppliers have continued to offer an increasing range of products, trending towards systems of continually increasing power conversion efficiency (PCE), the choice of reflected colours, and with a brodening range of semi-transparency options. Multiple new technologies have appeared on the market in recent years, utilising new functional materials and system design types.

2.1. Current Trends and Technologies in Conventional BIPV

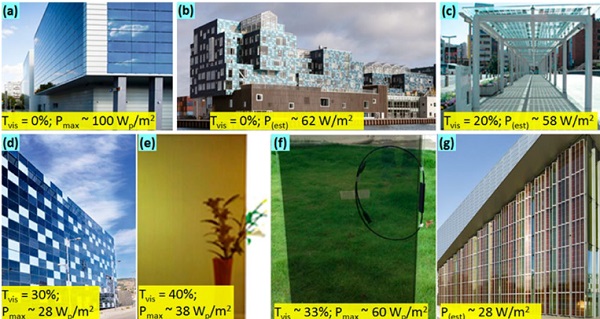

Multiple comprehensive reviews of recently-developed BIPV technologies and their performance characteristics are available, eg Biyik et al. (2017) and Vasiliev et al. (2019), with newer sources also continuing to appear in the literature. Fig. 1 provides an outlook on the BIPV technology types which have been commercialised widely at present, including the most commonly known semi-transparent patterned-semiconductor-based glazing systems. The naturally occurring (and fundamental) trade-off between glass transparency and power generation per unit area is approached differently in systems utilising different energy-conversion materials, resulting in a range of power-vs-transparency options, most of which do not result in colour-free visually-clear appearance.

Additionally, no pathways towards increasing the PV Yield (measured in kWh/kWp/year) compared to the roof- or wall-mounted monocrystalline silicon PV systems have been demonstrated in conventional BIPV so far, since these systems rely intrinsically on single-plane-oriented patterned active materials, usually deployed without sun-tracking or light concentration options. At the module level, the manufacturing scalability of large-area (> approx. 2m²) BIPV panels is only possible when tiled mono-Si wafers are laminated in-between glass plates, covering a substantial fraction of visual aperture (eg Fig.1 (c)).

This is due to the current range-to-resolution ratio limitations in industrial laser-patterning machines used to remove semiconductor material layers from parts of substrate area; also the lithography processes used to deposit a fine grid of conductors have similar limitations (eg Fig.1 (d, e, f)). With increasing thickness of the front coverglass used to laminate conventional mono-Si, which may be necessary for environmental safety reasons (eg wind load resistance, or if requiring walkable-roof safety assurance), the module PCE drops rapidly beyond ~3mm of the front glass thickness, for reasons such as geometric shading, light scattering and absorption by glass, refraction and reflectance.

While there is continued materials-related progress being made in terms of increasing PCE and novel PV materials (eg perovskites, kesterites, etc.) are being proposed for window-integrated PV systems, new approaches are required to broaden the range of available PV glass products. This is particularly true for the manufacturers targeting the development of high-transparency, area-scalable, and high-efficiency clear solar windows, which could then even resemble ordinary window types while providing energy savings and generation.

2.2. Trends and Challenges in Semi-Transparent Window-Integrated PV

In order to find innovative ways of designing semi-transparent solar windows of higher PCE and improved PV Yield characteristics (though only the PV Yield can be meaningfully compared to standard PV modules), not only novel functional materials but also modifications in the structure of PV-integrated glazing systems are required. Reinders et al. (2018), Vasiliev et al. (2016), Alghamedi et al. (2014), and others described several novel and recently-developed approaches to the WIPV glazing design utilising some results from the well-established field of luminescent solar concentrators (LSC), in combination with recent developments in the materials science of thin films, luminescent materials, and photonics. The task of designing highly transparent LSC-type devices of relatively high PCE involves considering fundamental trade-offs and theory limits described by Yang et al. (2017).

It is important to note that the main performance characteristics of any LSC-type device are governed by Eq. (1), where G is geometric gain, P is photon collection probability (often also called “optical efficiency”), and Copt is optical power concentration factor; detailed definitions for these parametersare available from Desmet et al. (2012).

![]()

In Eq.(1), the geometric gain is adjustable by the window system designer, and is largely governed by the window dimensions and the design of PV modules placed near window perimeter/edge areas to collect light. Typical values of G for ~1m2 windows are between ~5-10, dependent on whether solar PV strips are also placed around backside perimeter near glass edges. The photon collection probability, on the other hand, is a function of core technology used within the LSC-type glazing system, especially the luminescent and/or scattering materials and components used, eg glass panes chemistry, heat-mirror-type optical coating(s), any diffractive elements, and the overall optical arrangement of these components.

In most (or practically all) high-transparency large-a rea solar windows and LSC devices of different design types reported to date, the optical concentration factor Copt quantifying the radiation flux density reaching the near-edge solar cells is less than unity (data tables containing relevant literature-reported figures of LSC performance parameters have been reported in eg Vasiliev et al. (2019) and Reinders et al. (2018). This is due to the fact that allowing a substantial fraction of total incoming visible-range sunlight energy through the window strongly reduces the energy available for the wavelength conversion and internal redirection.

Luminescent materials can only convert a fraction of the available incident spectrum, with finite quantum yield (QY); only quantum dot materials can currently compete with organic-dye pigments reaching QY > (~80%); practically all inorganic phosphor materials have QY limited to max. ~30-40%, with very few of these capable of near-infrared excitation and emissions. Work is ongoing at multiple research groups worldwide on the design of LSC using giant Stokes shift inorganic phosphors capable of avoiding the well-known reabsorption problem, which is another limiting factor in large-area LSC design.

Another factor of special relevance to the industrial production of solar windows is the necessity to develop suitable and reliable technologies for the incorporation of inorganic phosphors (or semiconductor nanocrystals) into the glass-based industry-standard window design, without causing strong haze, and preferably avoiding the use of polymer slabs and any organics-based media not proven to provide decades-long lifetimes of solar exposure.

To the best of our knowledge, no other research group worldwide have so far demonstrated the industrialised development of high-power (tens of W/m2), clear, and size-scalable solar windows and published (Clearvue website 2021) flash-lamp PV I-V curve testing results for large-area (> 1m2) high-transparency glass-based clear and building standards-compliant solar windows (eg certified by IEC, UL, CE etc.) In particular, the performance data for windows demonstrating Ampere-scale currents at the maximum-power point, with large corresponding system voltages (VMPP near ~50 V) andtransparency levels exceeding 50% have not been so far published by any competitors.

Our most recent development results in large-area (1.91m x 0.95m) solar windows (now scheduled for export delivery to Japan) demonstrated electric power outputs (measured at STC) of up to 50.5 Wp (27.83 Wp/m2), proving both the scalability of technology and product development progress. Compared with the commercially available Clearvue solar windows of size 1.2m x 1.2m made 1-2 years ago, the current (2021-2022) window models of the same dimensions have shown the Isc improvements of up to 16.7% (~980 mA vs ~840 mA, at the same Voc and FF), as recently measured in field testing experiments, at the optimised (natural-sunlight) incidence-angle conditions, with the best incidence geometry being different from normal incidence. The latter feature (not reported in any conventional PV modules) makes Clearvue solar windows particularly suitable for BIPV applications on vertical walls.

3. Examples and Discussion

3.1. High-Transparency Window-Integrated PV: Installation Examples

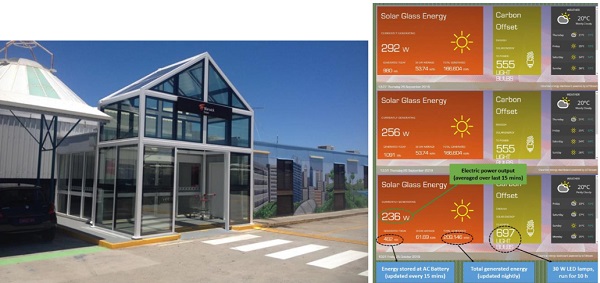

The first commercial property-based installation of Clearvue solar windows (Fig. 2) has been made at Warwick Grove Shopping Centre in Perth, in early 2019. A comprehensive analysis of its observed energy harvesting performance is available from Vasiliev et al. (2019).

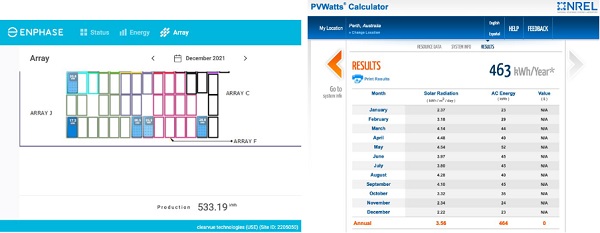

Solar windows of dimensions 1.2m x 1.2m were installed onto NE roof area (4 windows), NW roof area (4 windows), Nth wall (8 windows just below entry sign), and strongly-shade east wall (2 windows). The maximum instantaneous electric power output so far observed, measured at the AC battery by Enphase Envoy data-logging interface was just below 300 W; the yearly generation was ~0.5 MWh, in line with the predicted performance considering the relevant capture loss and system loss factors.

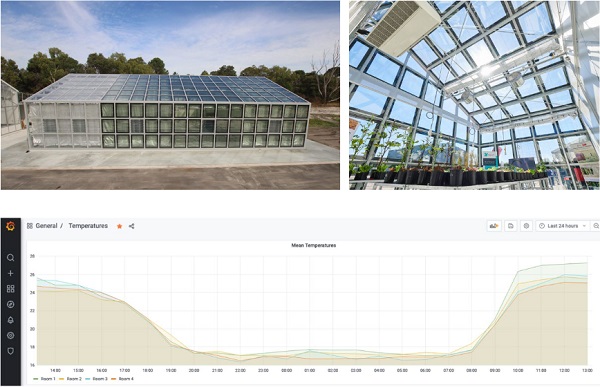

A more recent (2021) installation example of Clearvue solar windows is Murdoch University Solar Greenhouse (Fig. 3), in which 3 out of 4 grow-rooms (~50m2 floor area each) were built using solar windows on the north wall, on the 20-degree tilted north-facing roof, and also on the west-facing wall. 153 solar windows in total represented an installed capacity near 6.2 kWp, which has led to strongly offsetting the running costs of greenhouse during 2021 in terms of HVAC system operation. In summary, the winter-time daily electric energy consumption in Clearvue grow-rooms was at about a third of that needed to maintain microclimate in the reference grow-room glazed with conventional glass. The PV installation contained 13 Enphase 7+ microinverters each connected to a parallel bundle of ~12 windows; the system is also exporting energy to the grid, with the self-consumed energy fraction being near 70%.

The microclimate in each grow-room was finely controlled using a custom-designed HVAC system, keeping the temperature setpoints within +/-2 °C to optimise the plant growth. Even with this fine control of microclimate applied continually, the PV installation has offset min. ~40% of the total energy costs in Clearvue grow-rooms.

Fig. 5 shows the results of the summer-time PV Yield comparison made with a conventional PV or BIPV system installation of identical installed capacity placed onto a north-facing vertical wall in Perth. The energy production data for December 2021 from Enphase Envoy interface shows a 53.4% energy production increase, compared to that expected from a conventional PV installation of same capacity.

Similar PV Yield comparison results for the wall-based windows were also observed in other months (eg Nov 2021 and Jan 2022, when the weather was at its most stable for Perth). The PV Yields exceeding these available from conventional BIPV systems were expected, due to the design of Clearvue windows featuring the reduced angle-of-incidence sensitivity of electric power output. This makes these solar windows attractive for the (intrinsically multi-oriented) BIPV installations.

3.2. High-Transparency WIPV: Future Directions

With BIPV field installations continuing to grow worldwide, using an increasing range of products and different features, there is an increasing research attention to the contributions these systems will be making in terms of decarbonisation and sustainability.

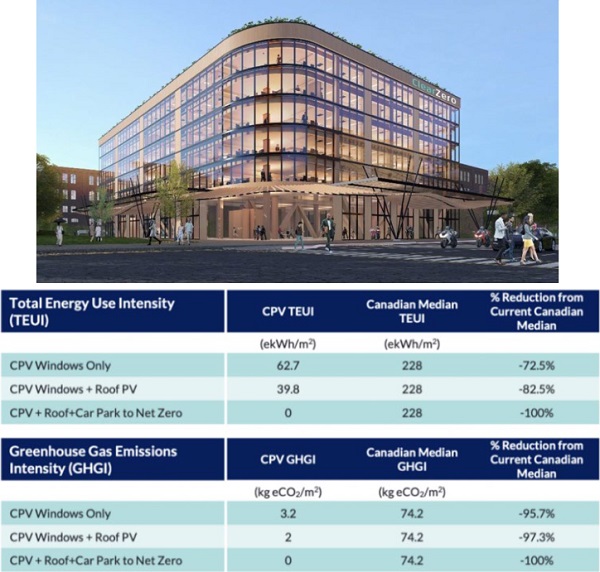

During the second half of 2021, ClearVue commissioned energy efficiency and sustainability specialists, Footprint (Canada) to develop an energy-efficient archetype model office building named “ClearZero” to demonstrate how ClearVue’s world-leading window integrated photovoltaics can be used to assist in the design of highly energy efficient, energy neutral buildings. We completed the design of an Archetype model building of 15,000 m2 internal area (an artist’s rendering based on architectural design software is shown in Fig.6 (Peacock, 2022)), to demonstrate how ClearVue windows can achieve a Net Zero or Near Zero energy-use building operation.

Modelling was completed on a design in Toronto, Canada, benchmarked against the Toronto Green Standard (TGS) from 2030 - one of the world’s highest standards of building performance. The Archetype was shown to achieve the highest level of performance under the TGS from 2030 (V6 Tier 1) and an ENERGY STAR score in the top 1% of Canadian office buildings for energy performance.

The Archetype demonstrates the energy performance of a low-carbon energy-efficient building design along with the renewable energy generation of the on-site photovoltaic arrays in the form of ClearVue’s PV glazing across all glazed surfaces – and 50% of the roof area of the building covered with a typical roof mounted PV array – together delivering approximately 40% of the energy needs for the building during its in-use phase. Net Zero energy use was also shown to be easily achieved by covering only 37% of the mandated car parking spaces for a building of the Archetype’s size and scale with additional roof-based PV.

ClearVue has achieved the 2030 TGS benchmarks all while maintaining window-to-wall ratios on the building elevations of 90% on the South, 70% East, 70% West and 40% North. These high fenestration ratios mean more natural light is available to end users of the building – a key factor in the movement towards “building wellness” design – all without compromising on the carbon footprint of the building.

4. Conclusions

In summary, we have provided an up-to-date outlook on the recent trends in the field of semitransparent BIPV from an industrial point of view, focussing on the development of high-transparency solar window systems. Recent solar window installation examples have been described, together with relevant technical performance characteristics, emphasizing the wide applications potential of this novel type of energy-generating transparent construction materials. The substantial role these high-transparency solar windows will play in the near future in helping decarbonise the built environments has also been illustrated, using the data and results from a third-party case study of an archetype building using Clearvue solar windows at a high fenestration rate, showing substantial carbon footprint reductions.

References

Alghamedi, R.; Vasiliev, M.: Nur-E-Alam, M.; Alameh, K. Spectrally-Selective All-Inorganic Scattering Luminophores For Solar Energy-Harvesting Clear Glass Windows. Sci. Rep. (2014), 4, 6632.

Avancis PowerMax Skala Datasheet (2022). Available online: https://www.avancis.de/en/products/powermaxrskala-40/(accessed on 13 January 2022).

Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.C.; del Ca o, T.;

Rico, E.; et al. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. (2017), 20, 833–858.

Clearvue Technologies website https://www.clearvuepv.com/frequently-asked-questions/ (accessed on 14 January 2022).

Desmet, L.; Ras, A.J.M.; de Boer, D.K.G.; Debije, M.G. Monocrystalline silicon photovoltaic luminescent solar concentrator with 4.2% power conversion efficiency. Opt. Lett. (2012), 37, 3087–3089.

IEA Renewables-2021, Executive Summary https://www.iea.org/fuels-and-technologies/solar (2021) (accessed on 13 January 2022).

Li, H.; Wu, K.; Lim, J.; Song, H.-J.; Klimov, V.I. Doctor-blade deposition of quantum dots onto standard window glass for low-loss large-area luminescent solar concentrators. Nat. Energy (2016), 16157. https://doi.org/10.1038/nenergy.2016.157

Peacock, B., Modelling finds building with WA company’s solar windows nearly eliminate operational emissions https://www.pv-magazine-australia.com/2022/01/13/modelling-finds-building-with-wa-companys-solar-windows-nearly-eliminates-operational-emissions/ (2022) (accessed on 13 January 2022).

Reinders, A., Kishore, R., Slooff, L., and Eggink, W. Luminescent solar concentrator photovoltaic designs. Jpn. J. Appl. Phys. 57, 08RD10 (2018).

Vasiliev, M.; Nur-E-Alam, M.; Alameh, K. Recent Developments in Solar Energy-Harvesting Technologies for Building Integration and Distributed Energy Generation. Energies (2019), 12, 1080. https://doi.org/10.3390/en12061080

Vasiliev, M.; Alameh, K.; Nur-E-Alam, M. Spectrally-Selective Energy-Harvesting Solar Windows for Public Infrastructure Applications. Appl. Sci. (2018), 8, 849. https://doi.org/10.3390/app8060849

Vasiliev, M.; Alghamedi, R.; Nur-E-Alam, M.; Alameh, K. Photonic microstructures for energy-generatingclear glass and net-zero energy buildings. Sci. Rep. (2016), 6, 31831.

Vasiliev, M.; Nur-E-Alam, M.; Alameh, K. Initial Field Testing Results from Building-Integrated Solar Energy Harvesting Windows Installation in Perth, Australia. Appl. Sci. (2019), 9, 4002. https://doi.org/10.3390/app9194002

Yang, C.; Lunt, R.R. Limits of visibly transparent luminescent solar concentrators. Adv. Opt. Mater. (2017), 5, 1600851.

Comments

Recent years have seen the development of numerous contemporary glass and window products based on unique interlayer types, metal-dielectric coatings, and innovative glazing patterns.