Date: 10 April 2017

Wellcan Aluminium will choose 10 aluminium profiles as samples, and examine the surface problem, profile’s angle and straightness.

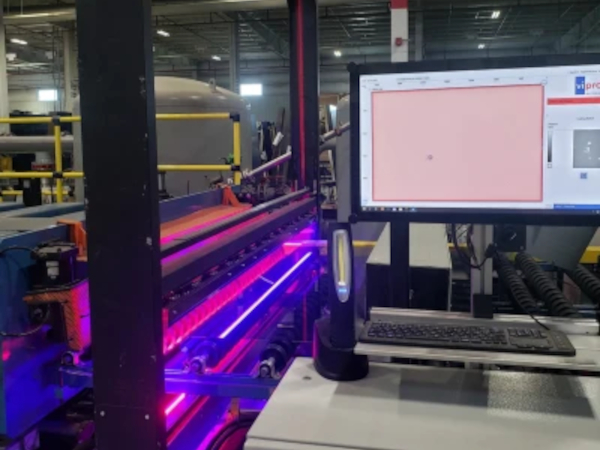

Except the normal examination,Wellcan Aluminium will use the section scanner imported from Israel to check the section of aluminium profiles precisely.

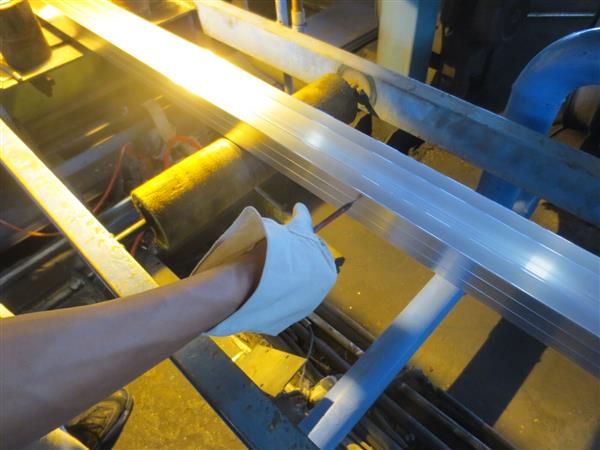

▼ Cutting the aluminium profile to get samples

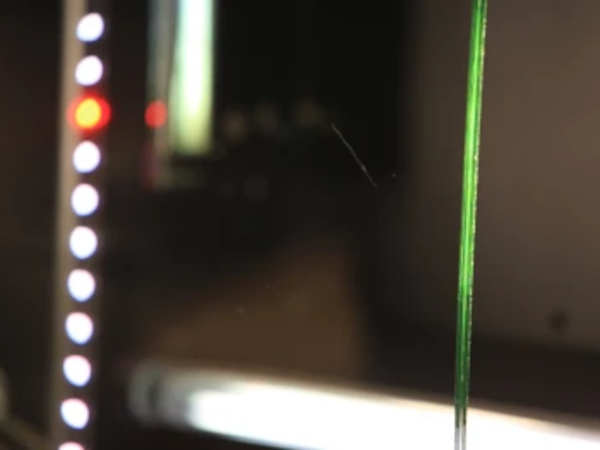

▼Checking the surface of aluminium’s profiles

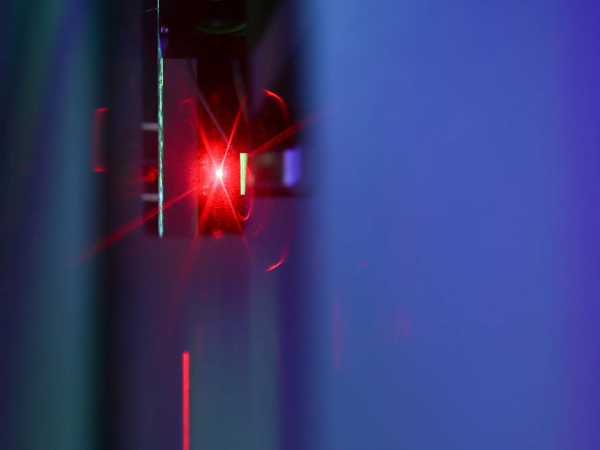

▼Examining the angel and straightness of aluminium profiles

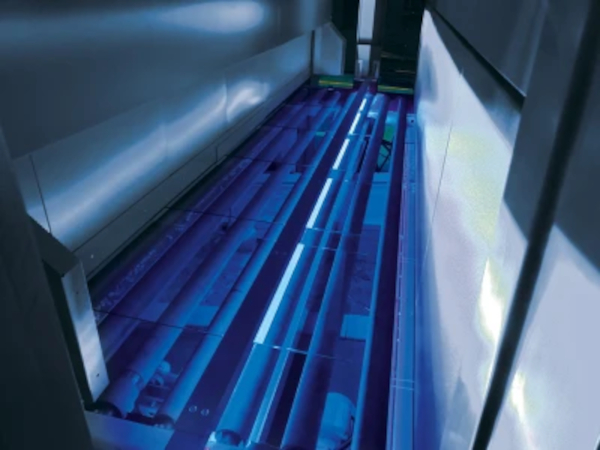

▼Scanning the section of aluminium profiles

600450

600450

Add new comment