Date: 14 December 2016

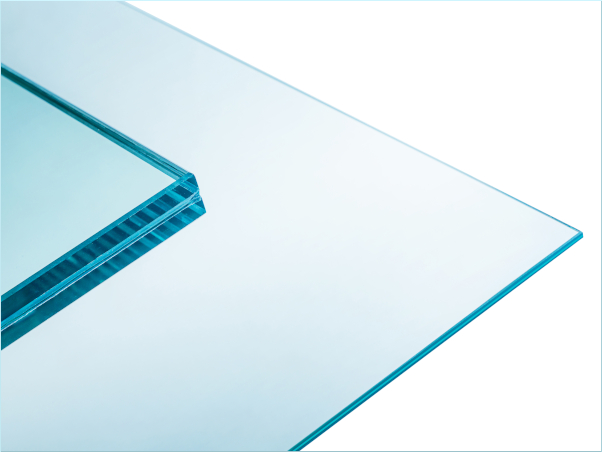

SolarWindow Technologies, Inc., the leading developer of transparent electricity-generating coatings for glass windows on tall towers and skyscrapers, and flexible veneers, today announced that it is expanding product development to include applying its electricity-generating coatings onto flexible glass – as thin as a business card (only 0.1-millimeter-thick) – that is flexible enough to be bent without breaking or cracking.

The company estimates that the world’s first transparent, electricity-generating flexible glass conservatively represents a $25 billion market.

Integrating transparent SolarWindow™ coatings with flexible glass creates new product opportunities for curved and non-flat surfaces in automotive, aircraft, and military applications.

Applying SolarWindow™ coatings on flexible glass allows for the flexibility of plastic with the durability, scratch-resistance, and ease of maintenance of rigid glass.

“Flexible glass could play a big role in window, canopy, smart building, and other building and transportation products. We believe that flexible glass can serve an even more valuable purpose by generating electricity using SolarWindow™ coatings,” said John A. Conklin, President and CEO of SolarWindow Technologies, Inc.

Demonstrated to the United States Congress, SolarWindow™ coatings are transparent, ultra-light weight, and generate electricity when applied in layers thinner than human hair.

When applied to a 50-story building, SolarWindow™ coatings achieve a one-year financial payback and generate 50-times greater energy than conventional rooftop solar, according to independently-validated engineering calculations.

Today’s announcement marks an important expansion of SolarWindow™ products, where engineers envision coating flexible glass using methods they have been developing for rigid flat glass, such as high speed (roll-to-roll) and large area (sheet-to-sheet) manufacturing.

Recently, SolarWindow reached a major product development milestone by conducting tests that showed its coatings successfully performed under test conditions designed to simulate the high pressure and temperatures of the ‘autoclave’ manufacturing processes used by commercial glass and window producers.

Autoclave-manufacturing is a common method of production for flat, curved, tempered and solar glass fabrication.

600450

600450

Add new comment