Date: 6 June 2018

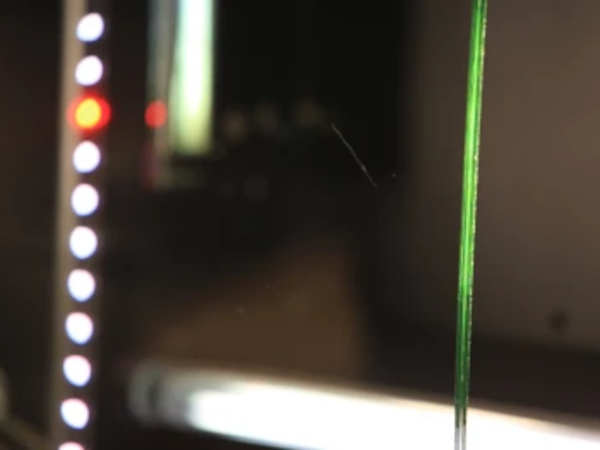

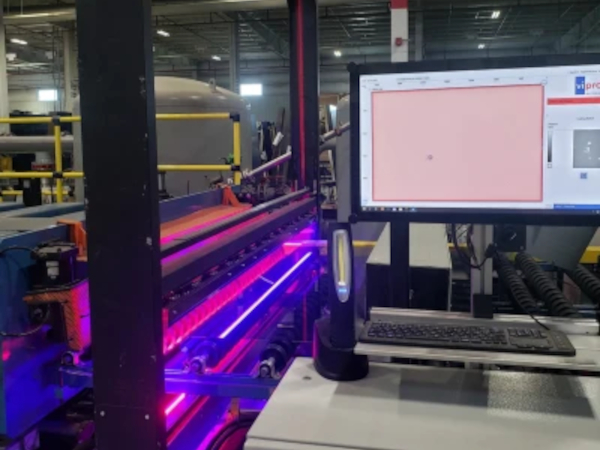

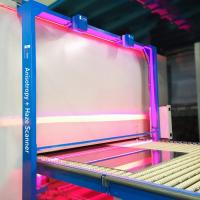

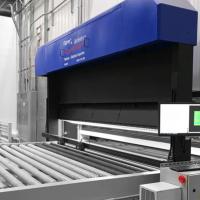

For the use of the LineScanner on a tempering furnace – which is now also able to check anisotropy and edge stress in addition to geometry, surface quality, edge quality and also DMC codes - we have created a real masterpiece in regards to a visual, non-destructive tempering quality check.

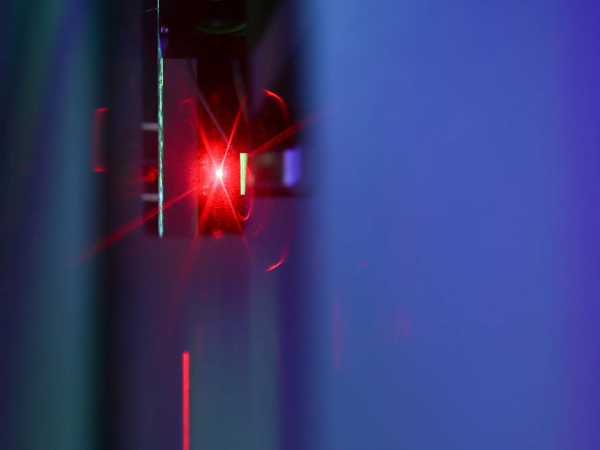

In order to avoid iridescence such as rainbow polarization spots, tapes or rings in the glass, the LineScanner can test internal stress zones which lead to a birefringence of the light easily and quickly.

With an inside view, you can understand. With an overall view, you can decide. With a far-sighted view, you can control things.

Glass quality control - We make quality visible

As an innovative company, Softsolution specialises in automatic glass inspection systems, glass quality assurance systems, electronic image capture and software development in the glass industry. Advances based on customised solutions and innovative technologies are opening up new perspectives for our customers and partners – sustainably and with foresight around the world.

Softsolution is setting new standards

Staying ahead of the competition means producing faster, more efficiently and more flexibly. These factors play an important role in the glass industry, where the exacting demands of customers and partners must be met. This is why we have devoted ourselves to the topic of glass for more than 15 years, specialising in glass quality control systems at the highest technical level in the glass industry.

Quality made in Austria

All our glass quality assurance systems and products are developed and produced at our location in Waidhofen/Ybbs in Austria – from individual components and software to the final finished product. As an all-in supplier, our service covers the entire process from the beginning of the planning phase right through to the implementation and manufacture of our products.

Personal advice

We will assist you as a competent partner. At Softsolution, we attach great importance to the highest levels of quality and safety. Convince yourself of our range of automatic glass quality inspection systems – we will be pleased to provide you with personal advice for customised solutions.

Softsolution

600450

600450

Add new comment