Date: 30 March 2016

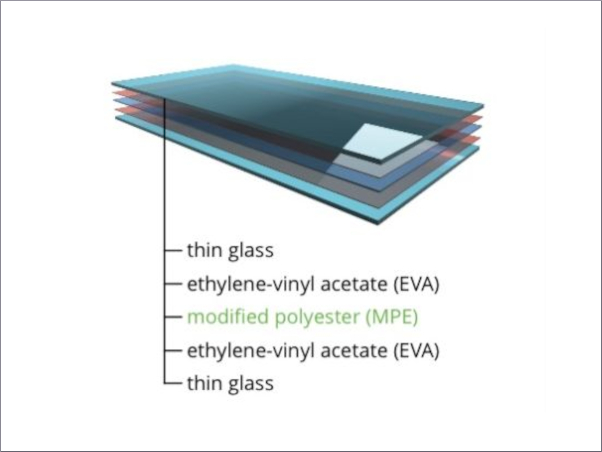

In the Innovation Award from German Industry, which will be presented on April 16, 2016, SCHOTT managed to make it among the four finalists in the category large companies with its ultra-thin glass.With a minimum thickness of 25 micrometers (microns), these innovative glasses are thinner than a human hair, flexible and yet robust.Thus they offer many advantages over other substrate materials such as plastics, metals or silicon. With properties such as minimum thickness and flexibility, which previously only polymers offered, they combine the classic chemical, physical and mechanical advantages of the inorganic material of special glass, such as transparency, optical quality, hermeticity (impermeability to humidity and oxygen), temperature stability, chemical resistance and mechanical strength. With these special qualities, the ultra-thin glass substrates from SCHOTT are an ideal material for use in printed and organic electronics.

SCHOTT will be presenting concepts on how it plans to transfer ultra-thin glass substrates into mass production for applications in organic and printed electronics together with development partners at LOPEC.

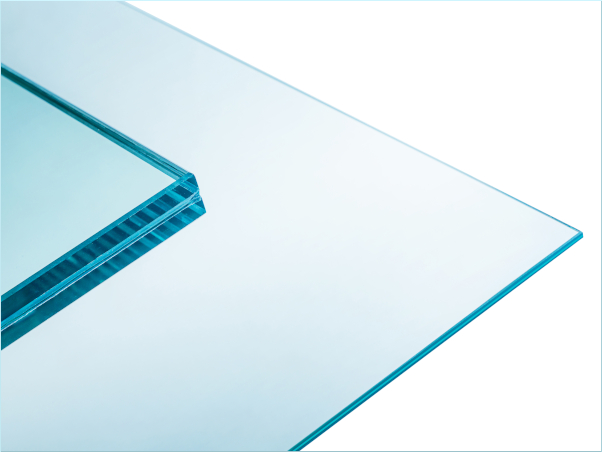

Flexible and yet robust: ultra-thin glass from SCHOTT. Photo: SCHOTT

Besides presenting products and solutions at its booth, SCHOTT also offers the following sources of information:

• Presentation at the conference that is being held simultaneously

Ultra-Thin Glass – latest achievements to turn the ideal substrate material into a ready-to-use solution, or: building-up an industry eco-system

Dr. Rüdiger Sprengard

Director New Business Ultra-Thin Glass, SCHOTT AG

Tuesday, April 5, 12:10 pm to 12:30 pm, Room 13b

• For journalists: Press briefing with Dr. Rüdiger Sprengard

Wednesday, April 6, 3:00 pm

SCHOTT Booth (Hall B0, Booth 106)

More information: FILM

Film on ultra-thin glass

SCHOTT Microsite ultra-thin glass

http://microsites.schott.com/milestones/english/solutions/irt/ultrathinglass.html?dimsdetected=1&ref=no-referer

SCHOTT is a leading international technology group in the areas of specialty glass and glass-ceramics. The company has more than 130 years of outstanding development, materials and technology expertise and offers a broad portfolio of high-quality products and intelligent solutions. SCHOTT is an innovative enabler for many industries, including the home appliance, pharmaceutical, electronics, optics, automotive and aviation industries. SCHOTT strives to play an important part of everyone’s life and is committed to innovation and sustainable success. The group maintains a global presence with production sites and sales offices in 35 countries. With its workforce of approximately 15,000 employees, sales of 1.93 billion euros were generated in fiscal year 2014/2015. The parent company, SCHOTT AG, has its headquarters in Mainz (Germany) and is solely owned by the Carl Zeiss Foundation. As a foundation company, SCHOTT assumes special responsibility for its employees, society and the environment. www.schott.com

600450

600450

Add new comment