Others also read

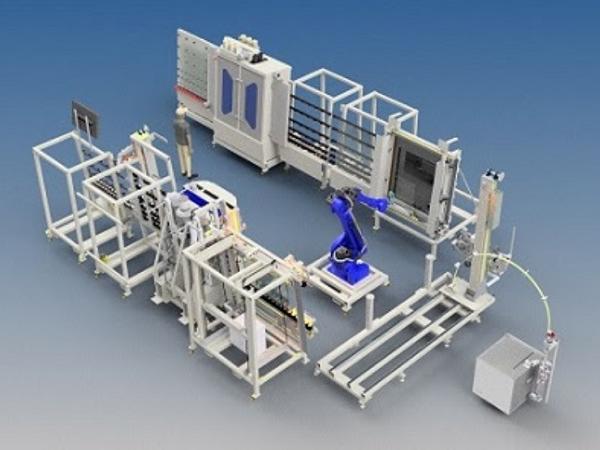

Online the video of the new Glass Unloader Art. GU by Forel. This new solution, presented for the first time in 2021 at GlassBuild America and at Vitrum is compatible with every kind of IG line.

Sparklike Laser Integrated™ device is non-destructive and IG-line integrated turnkey system for argon measurement.

A+W Software Ensemble for Highly Automated Insulating Glass Production in Lithuania

Şişecam Otomotiv A.S. has relied on LineScanners from Softsolution for many years and has recently invested again in two horizontal LineScanners for the detection of specially applied defect markings.

Tecglass technology brought to excellence, cosolidated in a printer concept for architectural glass mass production fully automatic with integrated scanning system.

How can infrared temperature measurement help your company to improve quality and process controls in various applications of the glass industry?

The future of the glass sector is networked and digital. For many years, investment in machine pools and automation promised both competitive and quality advantages, but today software is just as important.

The content of Schiatti stand at Vitrum is still “top secret”.

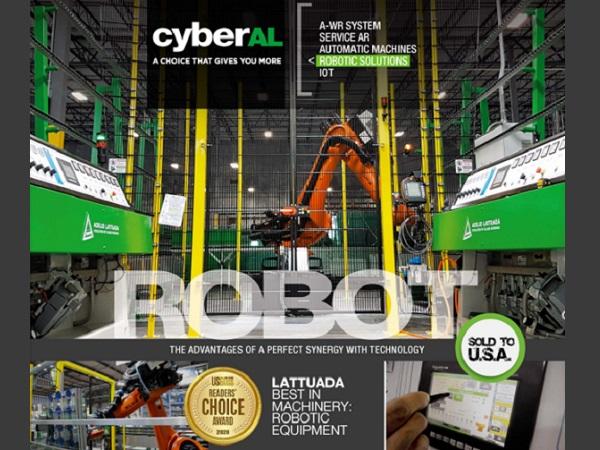

A place of honour will go to the Lattuada Robotic Solution (in partnership with Knittel Glass): robotic line consisting of two 13-wheels edgers, an in-line vertical washing machine and a robot.

After a period of uncertainty, the glass industry is approaching a new era with the Fourth Revolution and the Spanish company is channelling efforts in the research, design and development of new machines, software, and solutions 4.0.

Watch today's video to see how the combination of the DSC-A and the VSL-A cutting machine works in operation.

LiteSentry and SOFTSOLUTION are proud to announce they are under common ownership.

Scm Group and the European Investment Bank (BEI) have signed a new unsecured credit line running for several years of 50 million Euro.

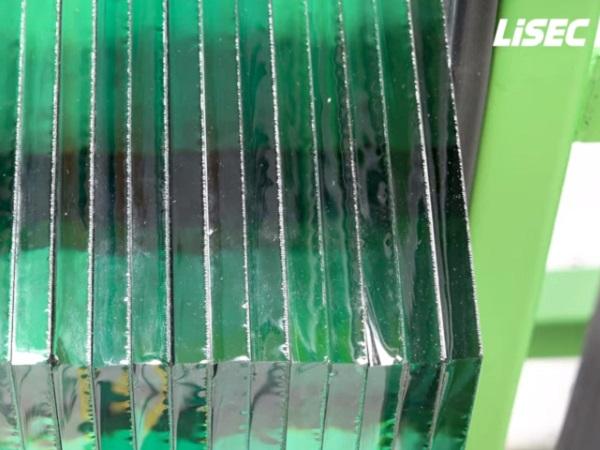

The campus theme day „thinking one step ahead” was all about the future at LiSEC. Find out more about the topic of unmanned production and KUKA in today’s LiSEC expert talk.

SOFTSOLUTION and LiteSentry, are pleased to announce a new partnership to support both companies’ long-term growth and success.

This two-day educational experience designed for glass fabrication industry leaders provides in-depth insight into the latest developments in glass fabrication equipment and software solutions in an up-close and personal setting.

The glass loader has been projected and built by SCHIATTI to automatically place glass sheets, positioned on a vertical surface, on the horizontal double edging machine.