Others also read

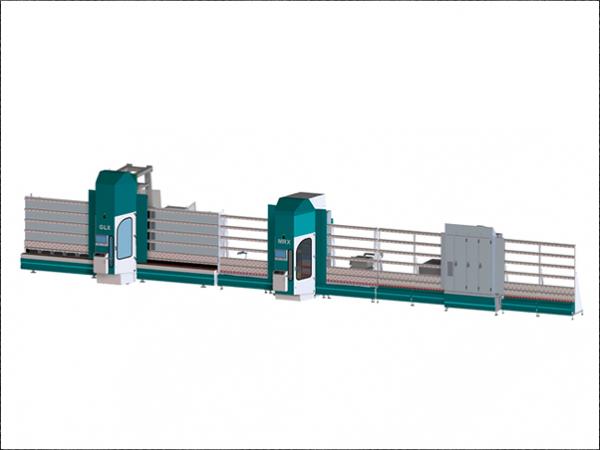

The MRX fully automatic milling and drilling machine delivers convincingly good performance and is easy to operate.

combiFIN is a compact but simultaneously highly efficient vertical processing line for flat glass with a thickness of typically 4 to 12mm.

A MappiSUPERTEMPER™ tempering furnace achieves the characteristics necessary to certify E30 glass for fire resistance.

Inside and out, interlayers from Trosifol prove their capabilities in structural and aesthetic applications... both sides of the Atlantic.

The Elb 9 + 2 is capable of producing a complex profile on the edge of the glass in a single pass without the need to process the glass on different machines or change setups.

Once again, the RCN view proved to be successful for both the attitude to guide the customers for their choice and for the active service supplied.

The glass panes are joined with fireproof silicone sealants and the resulting joints are only 2 mm wide. The pane edges are aesthetically finished with a strip of ceramic paint of appropriate width in any RAL colour.

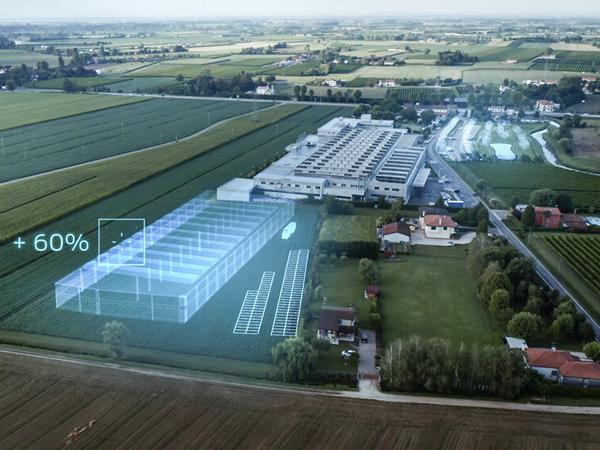

The enlargement of the Forel production plant (Treviso-Italy) is set to begin in 2021.

Vertec Mill is designed for high productivity purposes due to the possibility of drilling holes with opposed bits and milling cutters on every type of glass that has a straight side.

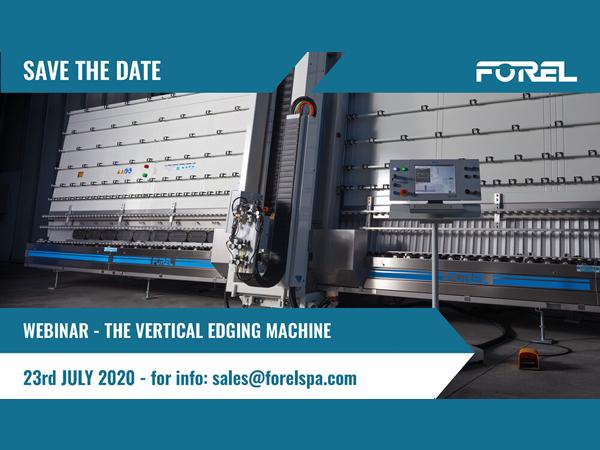

The webinars focus is to keep the customers updated with the latest technological improvements which are continuously developed from the Forel’s R&D department.

The Cms Profile is the ultimate vertical CNC work-center. It can mill, drill, grind, polish, engrave, and seam.

The fire-resistant glazing in the frameless system POLFLAM® BR, classified as EI 60. POLFLAM® glass, was also used for the fire-resistant doors in the staircases and is a definitive architectural feature of the building.

POLFLAM® fire-resistant glass has been used in the skylight over the hotel lobby.

New, advanced facility will serve growing Eastern Europe demand

Fire-resistant glazing with a satin finish is an effective visual barrier at the same time ensuring access of soft, diffused light. It is also neutral in terms of style and therefore blends perfectly with a multitude of different architectonic…

At Schiatti we have always thought that being next to you, telling you about our news and answering your questions, was an important part of our work, at least our understanding of it.

Polflam is not losing speed. Our R&D Department continues to work very intensively, developing new solutions and performing dozens of tests and studies.

Building with glass requires a few safety considerations.

The use of low-iron UltraClear™ Guardian glass made the project look light and transparent.

Officina Meccanica Schiatti Angelo s.r.l. is more than just machinery, they are partners who take time to solve your specific problems to add value to your operation.

Guardian Glass started full production on a technologically advanced new glass coater, July 6, at its second facility in Czestochowa, Poland.

After the great success of its first Webinar experience, Forel is inviting all its customers to a new appointment with glass processing technology.

In June, specialists from POLFLAM took part in the conference “Modern Glass Partitions – Key to Building Comfort”, which had been organised by the editors of “Świat Szkła” (Glass World) monthly magazine.

With the pandemic-related restrictions being lifted, we are gradually relaunching our training activities – in Poland and abroad. More and more dates are being fixed for events that had to be postponed.

Attila is the manager incharged of the tecnical service and design; he fulfils Schiatti working machines from the blank piece of paper to the machine in operation.