Others also read

As 2025 draws to a close, it’s a good time to reflect on business. We know for most glass processors, this has not been the easiest year.

Discover how the new Glaston TPS® PRO technology sets a new benchmark in insulating glass manufacturing.

A forward-looking collaboration between NBS and Forel shows how automation and large-format glass production are redefining the future of industrial glass manufacturing in Japan.

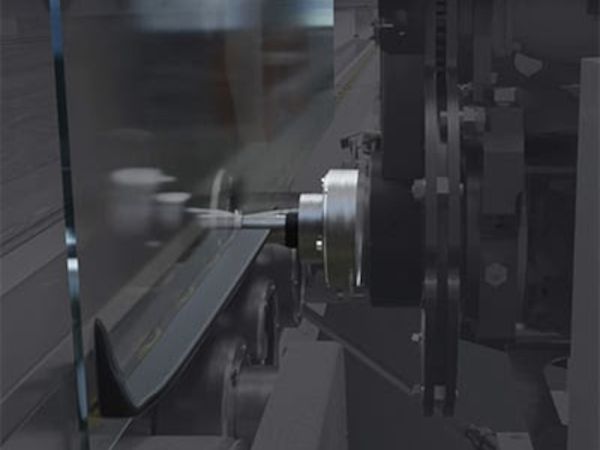

Its recent investment in the innovative LiSEC SRP-A system underscores their shared commitment to digitalisation and greater efficiency.

Discover how automated TPA application ensures accuracy, speed and reliable processing – even in large-format production.

LiSEC was named "Austria's Best Managed Company 2025" and took second place in the large companies category in Lower Austria at the prestigious Austria's Leading Companies Award.

The 2025 edition of GlassBuild America has concluded in Orlando, marking a record-breaking year for North America’s leading glass industry exhibition, which welcomed the highest number of exhibitors and visitors to date.

On 6 and 7 November, LiSEC welcomed more than 60 customers from Central and Eastern Europe and the Commonwealth of Independent States (CIS) region to Seitenstetten.

LiSEC is meeting challenges and emerging trends with innovative concepts and custom solutions.

From the GlassBuild 2025 show floor in Orlando, Forel & Quanex are highlighting the innovative collaboration that is bringing automation and spacer performance to the next level.

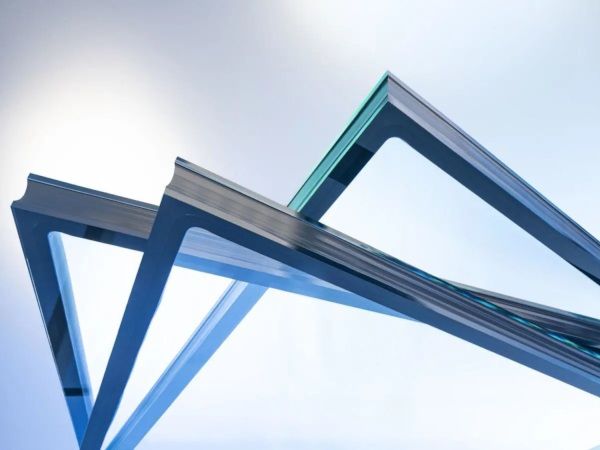

Forel introduces a new manufacturing solution for Triple Thin IGUs with Flexible Spacer, combining advanced automation, precision, and efficiency for next-generation insulating glass production.

The strengths and expertise of the MADE products to date will be bundled under the LiTROS brand, developed further and opened up to new target markets.

With its new plant in Port Talbot, Press Glass UK is consolidating three locations and boosting efficiency and growth thanks to LiSEC automation.

At GlassBuild America 2025, Glaston showcases its latest innovations in glass processing, emphasizing smart automation, energy efficiency, and production flexibility.

First IGU line with a small footprint and high speed in the UK.

A long-standing partnership driven by innovation, technology, and a shared vision for excellence in architectural glass.

Considering these six factors aids with installing the LiSEC machine considerably.

At Vitrum 2025, Forel showcased new technologies and solutions that push the boundaries of innovation and efficiency in glass processing.

LiSEC has been named ‘Austria's Best Managed Company 2025’. This competition was organised by Deloitte Austria, Raiffeisen Landesbank Niederösterreich-Wien and the business magazine trend.

Now online: the new video dedicated to the manufacturing of triple glazed units with thin inner glass using the Forel High Tech line with TA thermoplastic spacer applicator.

Austrian window manufacturer Felbermayer has invested in turnkey LiSEC technology to achieve fully automated, high-quality insulating glass production.

Discover how LiSEC machinery plays a vital role in enabling the production of extraordinary architectural elements in this success story.

The LiSEC Group is pleased to announce that the products of Schraml Glastechnik GmbH will be marketed under the LiTROS brand from now on.

The article contains recommendations from LiSEC technicians to help ensure smooth and reliable machine operation.

The LiTROS IG butyl semi-automatic provides an efficient solution for coating spacers with butyl hot melt adhesive. This easy-to-use station combines robust technology with sophisticated design.