Others also read

A Story of Vision, Growth, and Leadership

If you think glass repair and replacement always needs massive equipment and complicated access setups, this session might change your mind.

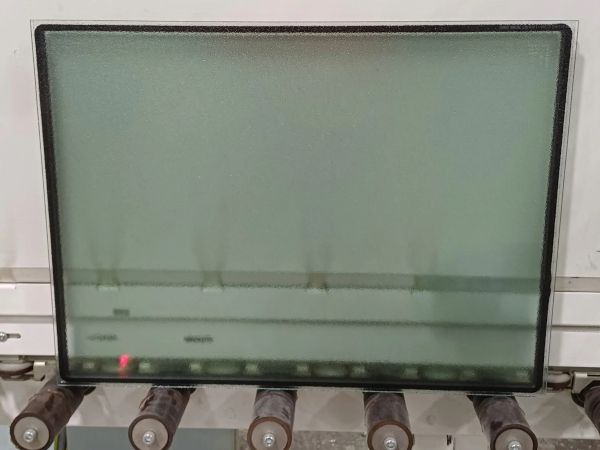

Şişecam has successfully commissioned the new coated glass line at its San Giorgio di Nogaro plant in Northern Italy, an investment realized with 25 million Euro.

For over thirty years, CMS Glass Technology has been developing flat and curved glass processing technologies with a focus on continuously improving products, services and skills.

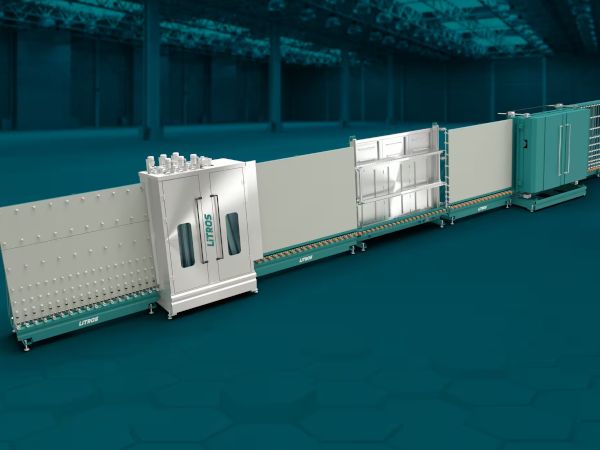

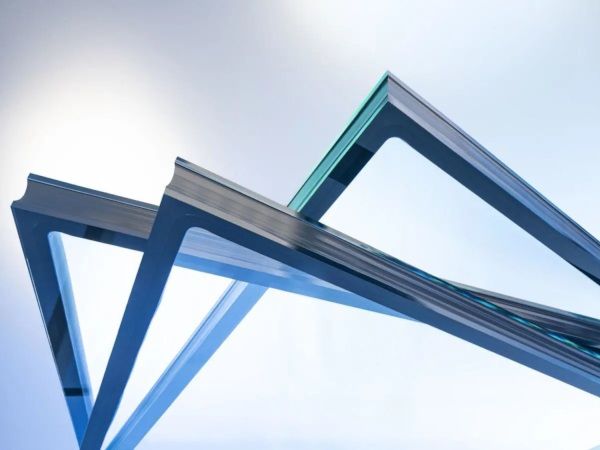

The vertical LiTROS insulating glass line offers a good solution for the efficient production of insulating glass units with rigid spacer frames.

At Fensterbau Frontale in Nuremberg, the HEGLA Group will be focusing on solutions for efficient storage and logistics of glass, windows and long goods profiles.

Xinruineng ensures compliance with China’s 85% argon requirement by using Sparklike’s non-destructive gas measurement technology to guarantee reliable energy performance in insulating glass units.

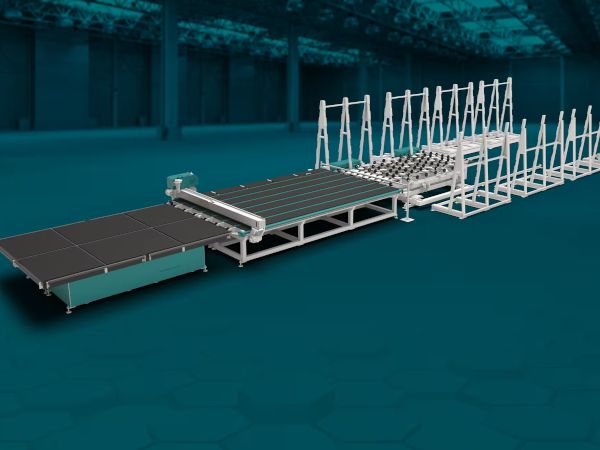

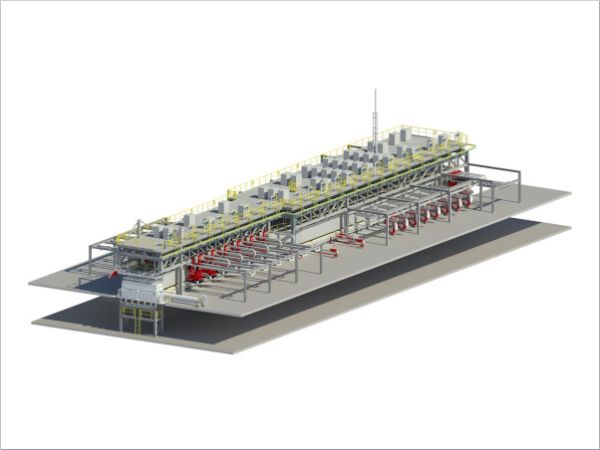

The LiTROS glass cutting line is a sophisticated, modular solution for industrial processing of float glass.

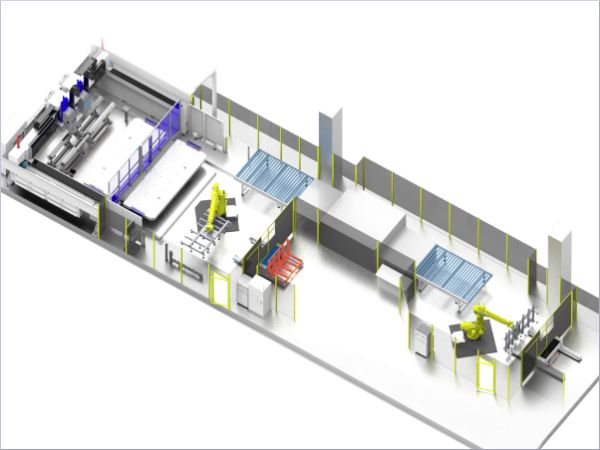

TUROMAS presents its €1.5 million investment project to the Government of Aragon and its application for Just Transition Funds and FITE funding.

Knowing its roots helps shape the future. From Tamglass in the 1970s to Glaston today, the company’s windshield-bending journey has been driven by curiosity, craftsmanship and teamwork.

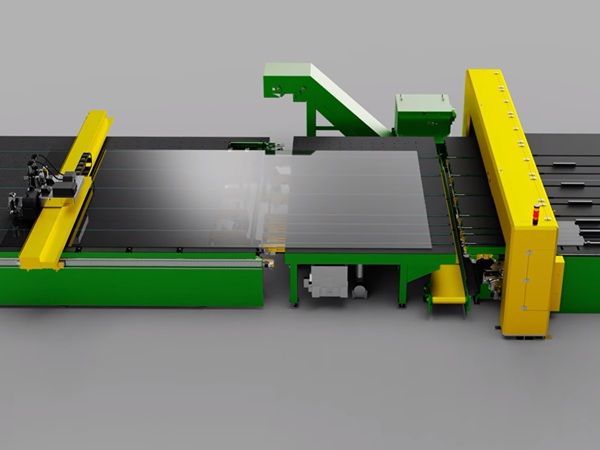

Hegla has released a new video showcasing the ProLam Neo LSR, its fully automated, high-performance cutting solution for laminated safety glass.

The new line, with an annual capacity of 6 million square meters, will operate alongside the existing coated glass line.

Kuraray’s Advanced Interlayer Solutions (AIS) Division is excited to announce the opening of a new office in Dubai.

Invisible Shield Easy-Clean Protective Coating/Shower Treatment. Seals glass against water stains.

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

Zero worries. Maximum productivity.

A smart solution for lighter, slimmer, and more efficient insulated glass units.

The SplitFin is a vertical processing line for flat glass with two processing towers: EPS-B for edge processing and MRX-B for internal processing.

HORN Glass Industries delivers industry-leading float tin bath solutions designed for precision, quality and long-term performance.

Glass for Europe has stepped into the spotlight to ensure that advanced glazing technologies are fully recognised as strategic materials in Europe’s upcoming Advanced Materials Act.

As customer expectations for energy efficiency and glazing performance continue to rise, SafeGuard Glazing Supplies has reinforced its commitment to quality with the Sparklike Laser Portable™ 2.2.

As Europe accelerates its shift toward a circular economy, this joint position paper highlights why flat glass must move from a linear to a truly circular model in construction.

CMS aura is the vertical dry seaming machine designed for those seeking efficiency, simplicity, and savings in the glass processing workflow.

Discover how the new Glaston TPS® PRO technology sets a new benchmark in insulating glass manufacturing.