Others also read

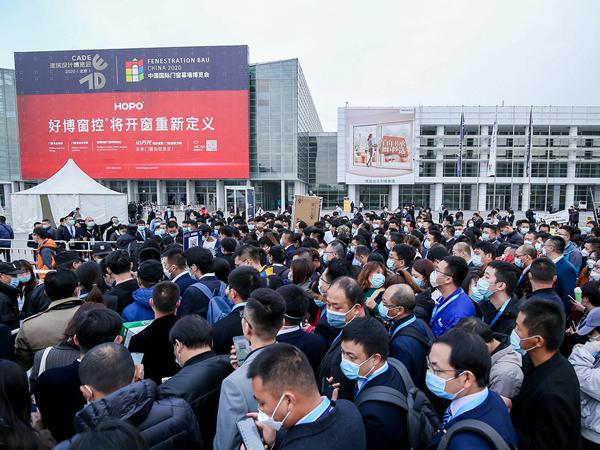

BAU China, the leading trade fair in the Asia-Pacific region for “Building Systems Solutions, High-End Technologies and Materials” was held from October 29 to November 1, 2020.

Check out the LiSEC Campus and watch the latest expert talks!

CulletScanner with tilt-function - new Video available! Automatic fragmentation image analysis with optional polarization function.

Live demos, talks with our experts and in-depth analysis of the main trends of the glass market.

Smaller fabricators are consistently overlooked when companies design, market, and sell ERP solutions. A+W Software is changing that for glass fabricators with the launch of our newest product called A+W iCut.

Between 27 and 30 October 2020, the virtual LiSEC Campus will be welcoming visitors from around the world.

SCM and CMS, the two benchmark brands in the Scm Group's machinery sector, key players in the 57th edition of Smau, the annual Innovation trade fair held at the Fieramilanocity on 20 and 21 October.

Experience the first ever virtual LiSEC Campus!

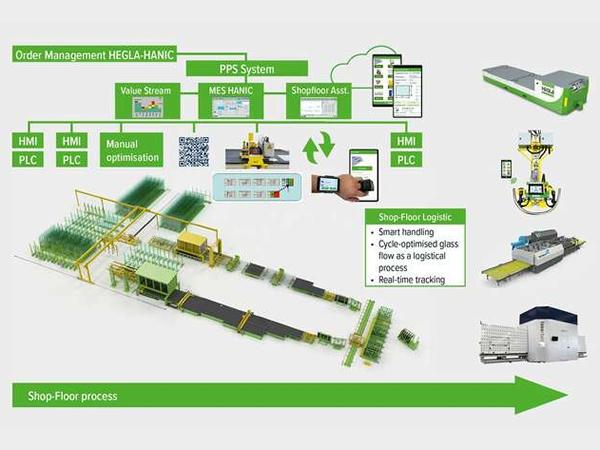

The glass production of the future will be fully networked and digitalized. Alongside digital support for employees, it will provide quick insight into machine capacity and even the current position of a specific pane.

In an interesting Online Seminar about the LiSEC PlusLam you can benefit from the full LiSEC know-how at our virtual exhibition - don't miss it!

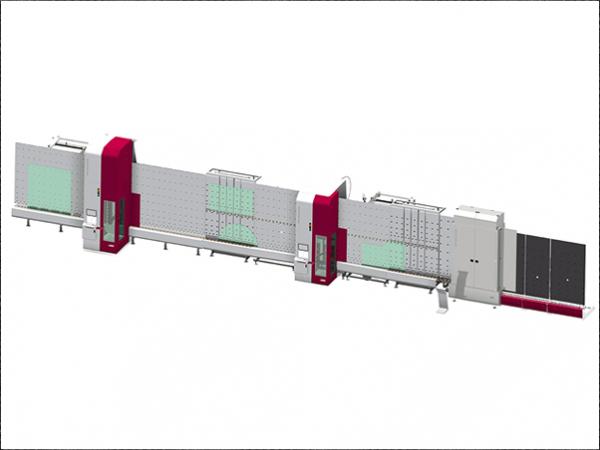

The SplitFin is an integrated and continuous solution for fast and uncomplicated processing of the most common glasses and dimensions.

High-quality glazing requires high-quality systems for the quality control of glass.

After extensive tests and research Tryba has decided to use the reliable Quality Scanners from Viprotron.

Thanks to the latest developments, the LineScanner Management Console and artificial intelligence are now used to optimize processes.

The Cms Profile is the ultimate vertical CNC work-center. It can mill, drill, grind, polish, engrave, and seam.

Unlock the next step of automated production | October 7th at 4 PM italian local hour

Today 274 employees work for the Turkish company Tamcam Oto Cam Sanayii A.S., checking anisotropy and edge stress with a horizontal LineScanner from SOFTSOLUTION.

Every customer project is unique and this is how we see the cooperation with our customers who trust in automated quality assurance systems from SOFTSOLUTION.

In a year of uncertainties regarding industry events and trade fairs, LiSEC is once again setting benchmarks with its own innovative approach.

Gethke Glas Gronau GmbH & Co. KG has relied on quality assurance systems from SOFTSOLUTION since 2011.

With the LiSEC LONGLiFE PC upgrade, you can bring your existing system right up-to-date, so that it can be operated and serviced for many more years.

Meet SOFTSOLUTION North America Inc. virtually and learn more about our automated quality assurance systems (LineScanner, CulletScanner, VirtualDigitizing).

2020: A year full of unforeseen developments. All the more reason to tread new, innovative paths – also when it comes to trade fairs.