Others also read

The 2025 edition of GlassBuild America has concluded in Orlando, marking a record-breaking year for North America’s leading glass industry exhibition, which welcomed the highest number of exhibitors and visitors to date.

On 6 and 7 November, LiSEC welcomed more than 60 customers from Central and Eastern Europe and the Commonwealth of Independent States (CIS) region to Seitenstetten.

LiteSentry – Softsolution will participate in Eurasia Glass Fair 2025, held from November 15–18 at the TÜYAP Fair and Congress Center in Istanbul.

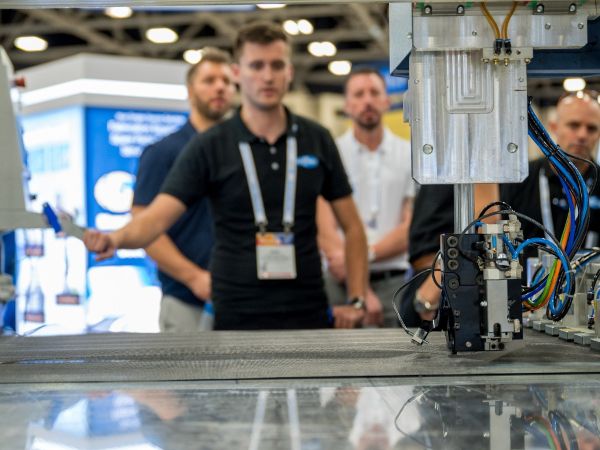

From the GlassBuild 2025 show floor in Orlando, Forel & Quanex are highlighting the innovative collaboration that is bringing automation and spacer performance to the next level.

Forel introduces a new manufacturing solution for Triple Thin IGUs with Flexible Spacer, combining advanced automation, precision, and efficiency for next-generation insulating glass production.

New model FG for fast grinding and simultaneous edge seaming.

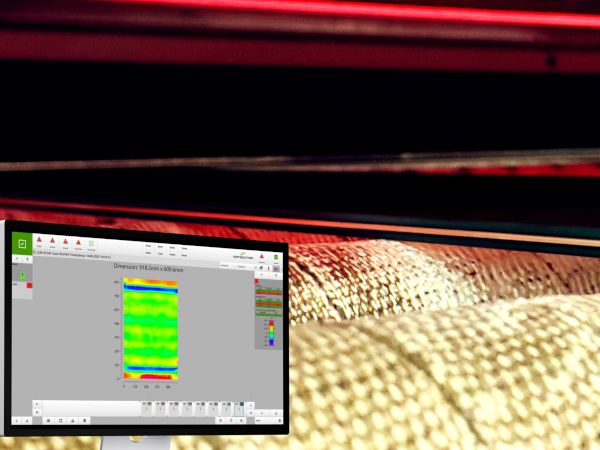

Automation and precision are redefining flat glass processing. In this expert article, Mika Eronen of Global Glass Specialists explains how dual-metric scanning is transforming quality control and boosting yield across the industry.

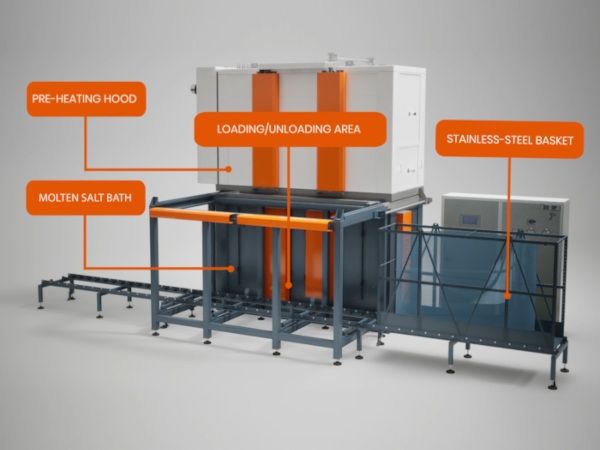

TK S.r.l. showcases how chemical tempering is transforming glass processing with its advanced TK Chemical Temper ovens and new 3D video.

Visit Booth #9048 to meet the experts from LiteSentry, Softsolution, and Strainoptics and experience live demonstrations of cutting-edge inspection systems.

Unelko’s Invisible Shield & IS Pro 15 Nano Glass Coatings, Architectural Glass Solutions for Reduced Cleaning & Maintenance, Cost and Sustainability!

Uniglass Solutions Oy, part of the Glaston Group, has appointed Pyry Ollonqvist as General Manager, effective November 1, 2025.

When perfection matters, even the slightest bow counts. The Bow Sensor keeps your production line running smoothly with real-time precision and total control.

Improved net sales and profitability, challenging market conditions continued

Explore how Glaston is reshaping the customer experience.

Viprotron has unveiled its latest innovation — the Bow Sensor, a cutting-edge solution designed to detect and control glass deformations, or “bows,” early in the production process.

Autopilot ensures a smooth start for a first-time tempering operator at OviBest

Glaston Corporation will publish its January–September 2025 Interim Report on Thursday, October 30, 2025 at around 8.30 a.m. Finnish time.

At GlassBuild America 2025, VIPROTRON will demonstrate how its latest inspection technologies are transforming industrial glass production — optimizing measurement, control, and quality across the entire production line.

At GlassBuild America 2025, Glaston showcases its latest innovations in glass processing, emphasizing smart automation, energy efficiency, and production flexibility.

First IGU line with a small footprint and high speed in the UK.

A long-standing partnership driven by innovation, technology, and a shared vision for excellence in architectural glass.

CMS proxima is the automatic dry horizontal seaming machine designed to meet the needs of small to medium-sized glassworks looking to optimize their production process without making major investments.