Photo source

CMS Glass Technology

Date: 14 October 2025

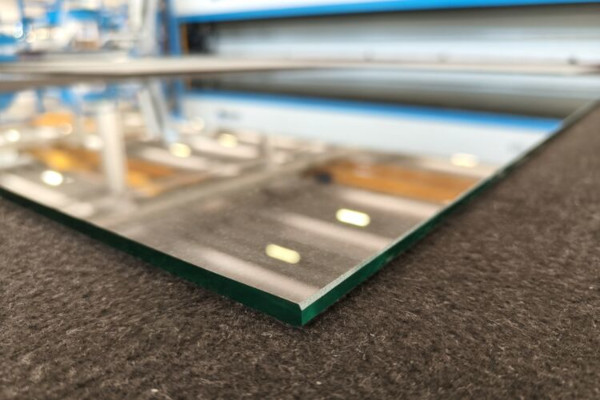

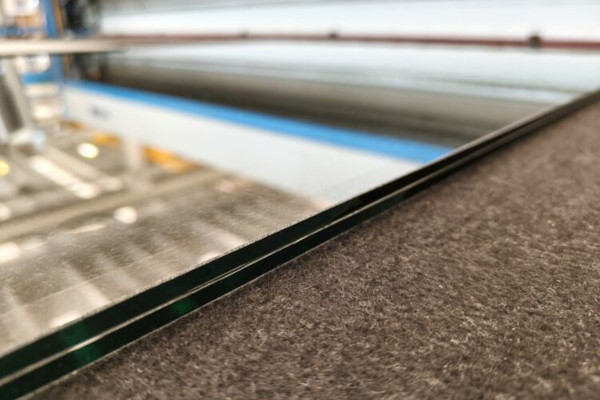

CMS proxima is the automatic dry horizontal seaming machine designed to meet the needs of small to medium-sized glassworks looking to optimize their production process without making major investments.

Compact, automatic and easy to install, proxima pairs perfectly with both tilting cutting tables for monolithic glass and those for laminated glass.

Why choose proxima?

- Unique in its class, proxima allows seaming of the glass edge directly on the cutting table, avoiding additional handling.

- It is a compact machine with a small footprint and can also be used in stand-alone mode with a simple support table.

- Easy and quick to install, even independently, proxima is immediately operational, requires minimal maintenance, and automatically adapts to the length and thickness of the glass.

- The dry processing with dust extraction eliminates the use of water and the disposal of sludge, significantly reducing the machine's operating costs.

- Perfect even for low-emissivity coated glass (Low-E), it ensures operator safety and the processed glass does not require immediate washing.

A practical solution to optimize processes, reduce costs, and increase productivity with ease.

600450

600450

CMS Glass Technology

2025-10-14T06:00:00

CMS proxima: the simple and compact dry horizontal seaming machine

glassonweb.com

Add new comment