Others also read

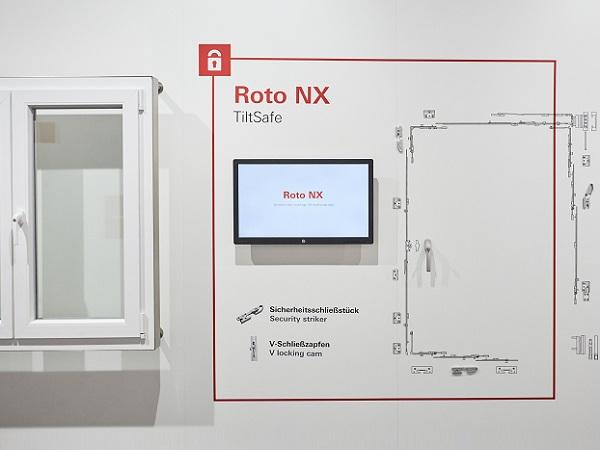

Straight after “Fensterbau Frontale”, Roto reported that the market premiere of a “Tilt&Turn hardware system for windows and balcony doors shaping the industry once again” enjoyed a “highly positive” reception on balance.

As a colorful highlight the new tram station in Linz snuggles up between the modern shopping center and the grey residential complex. Here, almost 1.400m² of colored laminated safety glass protect the waiting passengers from wind, weather and the…

In cooperation with the company Forel, a vertical line scanner was installed at the Kosovar company M-Technologie after the washing machine on a Forel insulating glass line.

In 2018, the CDE AquaCycle A900 thickener, with a capacity of 900m³/hour joins the CDE leading water recycling suite of products to bridge a gap in the market.

IGE is pleased to expand once again with the addition of window, door, and curtain wall machinery.

Glass South America 2018 will be for FOREL (stand 679) an important opportunity to present to all visitors the latest innovations developed, especially concerning IGU machinery.

The cooperation between LiSEC and Cristaleria Reina started in 2002, 2008 the production equipment was 80% LiSEC machines.

Diamut takes the stage at this unmissable event, held during the most biggest trade fair in Asia dedicated to glass processing.

Clarke Facades are delighted to welcome the arrival of their new Emmegi Satellite XT, 15m, 5 axis CNC machine into the fabrication branch of our business – Clarke Offsite.

Taking on the challenges of the future: the history of elumatec.

The main reason why Uyut Stil opted for LiSEC machinery is the fact that LiSEC offers solutions for every production step in glass processing.

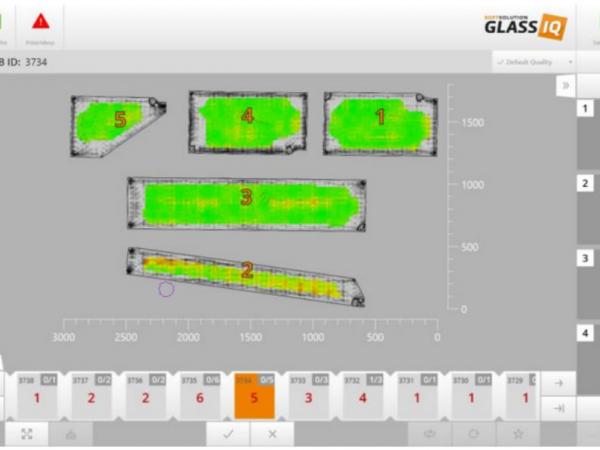

CE Glass Industries invested in a LineScanner from Softsolution to enhance efficiency to a great extent.

Schmalz has developed the system especially for CNC machining centers made by Bystronic.

FOREL, leader manufacturer of machinery for flat glass and double glazing industries, will attend Fensterbau Frontale 2018.

LiSEC delivers the first laminated glass line developed and built in-house.

This year Adelio Lattuada company celebrates its 40th anniversary!

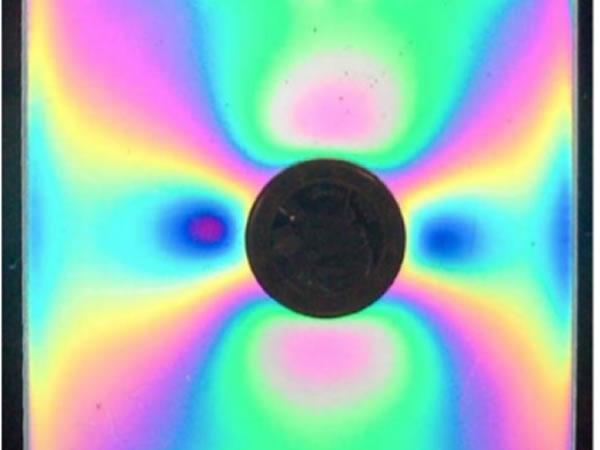

A recently completed research project investigated the development of a standardised and non-destructive test method for determining anisotropies.

"Transparent glass" is the name of a project with the aim of assessing and optimising the quality of toughened and heat-strengthened (semi-tempered) glass achieved using photoelastic methods.

Hitherto it has only been possible to determine the product quality of thermally tempered glass by means of destructive testing.

A LiSEC automatic cutting line with loading system was recently installed at Glass 360, a newly formed glass processing company in Queensland.

Here is an example of Schiatti Angelo's line of fully automatic double edgers.

Glass fabrication machinery experts, HHH Tempering Resources (HHH), and glass edging and polishing equipment provider, Hiseng, anticipate 2018’s glass fabrication needs with a new product partnership.

The TU Darmstadt is one of the leading technical universities in Germany and known worldwide for its pioneering and research achievements.

The technology line at POLFLAM production plant shall be expanded by a new tool, i.e., a glass processing centre.