Others also read

Glaston has entered into a cooperation with Leadus, a specialist in vacuum insulating glass (VIG) technology, to further develop advanced glass manufacturing solutions.

Glas Trösch expands its digital service portfolio with the launch of new browser-based configurators designed to simplify and optimize the planning of individual glass solutions.

The SANCO Group is pleased to welcome VAK Insulating and Design Glass from Slovakia as a new member of its Europe-wide network.

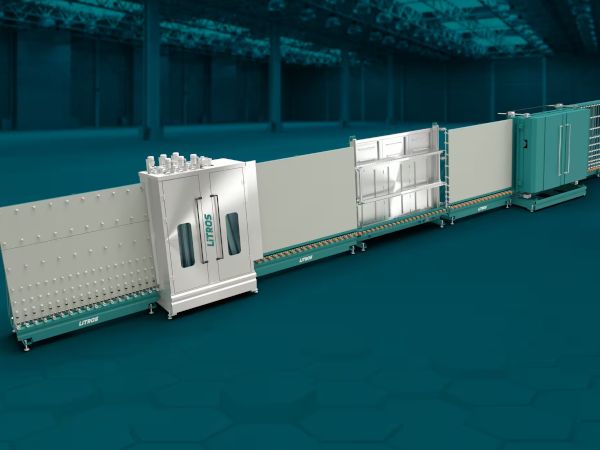

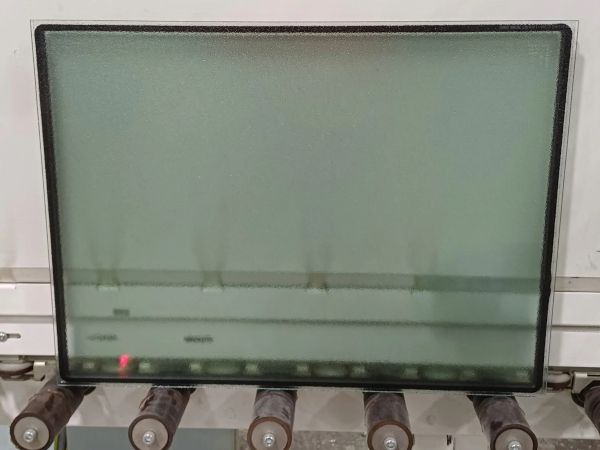

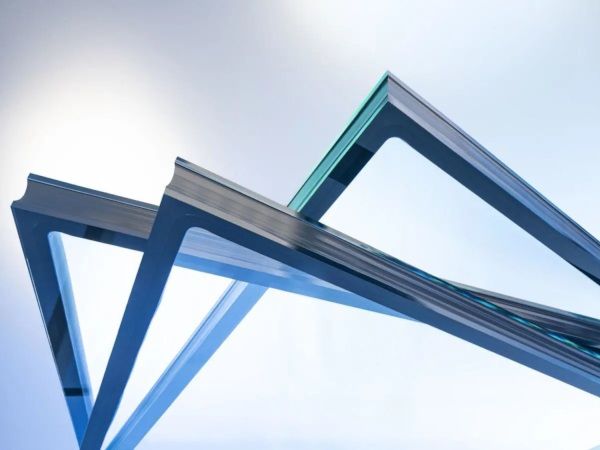

The vertical LiTROS insulating glass line offers a good solution for the efficient production of insulating glass units with rigid spacer frames.

Thiele Glas enhances its quality control with the installation of the Temper Scanner by Viprotron.

Xinruineng ensures compliance with China’s 85% argon requirement by using Sparklike’s non-destructive gas measurement technology to guarantee reliable energy performance in insulating glass units.

Saint-Gobain Glass UK is launching PLANITHERM® NEO, an advanced thermal insulation glass, designed to meet the evolving performance, aesthetic and sustainability requirements of the UK window and door market.

Soft market continued, profitability supported by productivity improvements.

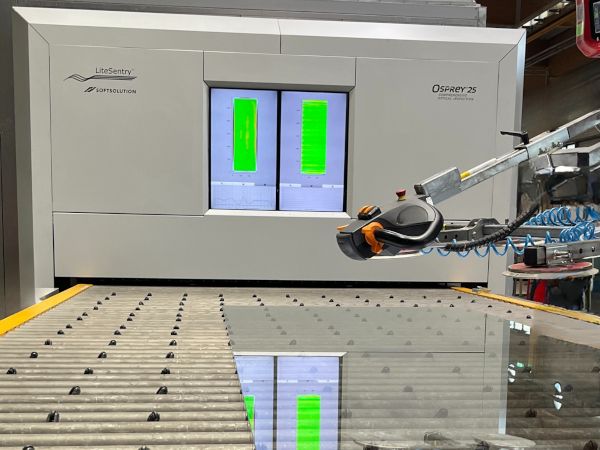

LiteSentry - Softsolution - Strainoptics will present their latest innovations in glass quality inspection at the 2026 Building Envelope Contractors (BEC) Conference.

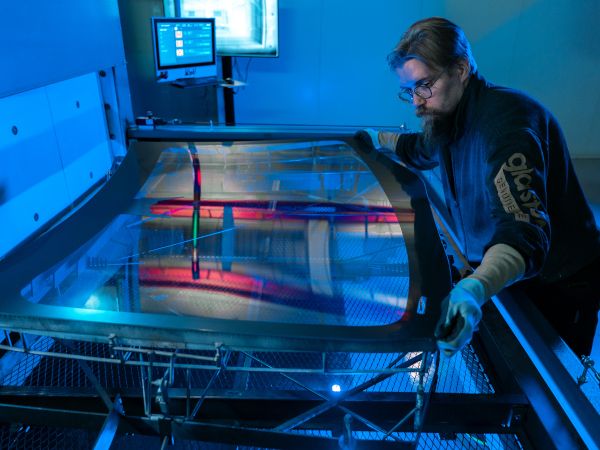

Knowing its roots helps shape the future. From Tamglass in the 1970s to Glaston today, the company’s windshield-bending journey has been driven by curiosity, craftsmanship and teamwork.

Project Scope: Inspection for All Types of Distortion, Anisotropy, Edge Stress, and Surface Quality.

New Group CEO brings 25 years of industrial automation leadership to global glassquality companies

FGIA has released an updated specification outlining key design considerations for multiple-cavity insulating glass units.

Sparklike, a global leader in non-destructive gas measurement solutions for insulating glass units (IGUs), announced the appointment of Sasu Koivumäki to its Board of Directors.

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

This year marks the 10th anniversary of Sparklike Laser Portable™, a major milestone in the development of non-destructive gas measurement for insulating glass units.

Glaston supports the more demanding automotive glass market with advanced processing technologies and consistently superior optics.

Innovative residential project impresses with sustainable glass solution

As customer expectations for energy efficiency and glazing performance continue to rise, SafeGuard Glazing Supplies has reinforced its commitment to quality with the Sparklike Laser Portable™ 2.2.

As 2025 draws to a close, it’s a good time to reflect on business. We know for most glass processors, this has not been the easiest year.

Discover how the new Glaston TPS® PRO technology sets a new benchmark in insulating glass manufacturing.

Vitro Architectural Glass celebrates triple recognition at the 2025 Product Innovation Awards, with BirdSmart®, Sungate ThermL™ and VacuMax™ VIG honored for their standout performance and innovation in architectural glass.

Saint-Gobain Glass: INSIO® becomes the first tempered vacuum glazing with 0.3–0.5 W/m²K insulation to earn CE marking

ISOLAR Glas has announced that it will cease production at its Klagenfurt, Austria facility at the end of the year.

Vitro Architectural Glass is marking a landmark year as several of its most influential Solarban® products reach major performance and innovation milestones.