Date: 10 October 2018

Schüco presents the successor to the AF 300: the AF 310, a new four-axis CNC machine which, with its intelligent control, the latest milling spindle technology and easy operation, ensures maximum dynamism and precision during machining. The AF 310 delivers maximum performance at every machining level and also impresses in terms of cost effectiveness and efficiency.

Schüco AF 310 CNC processing machine

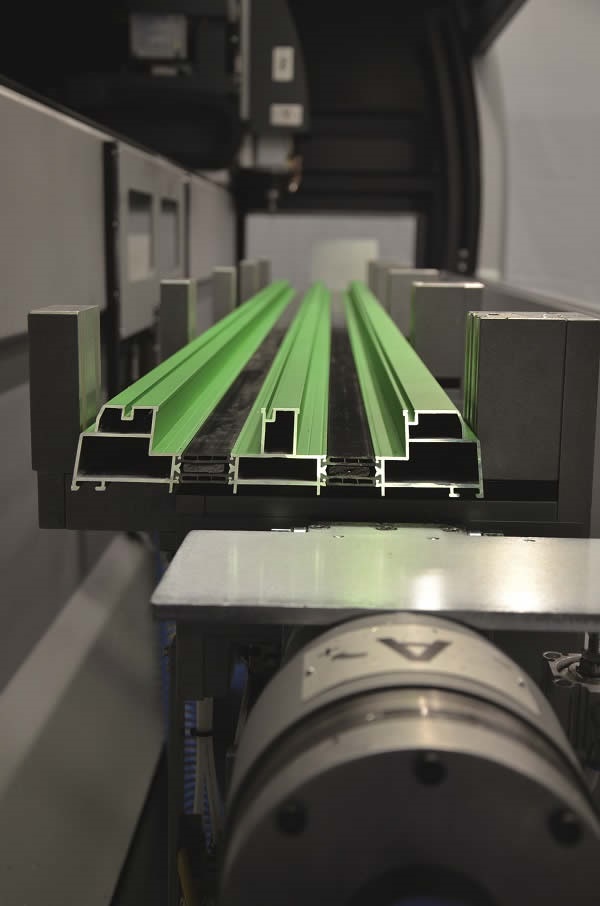

The Schüco AF 310 also works extremely accurately with large loads; it can easily machine steel with a wall thickness of up to 3 mm. Thanks to the swivel axis with a swivel range of +/- 110°, the Schüco AF 310 enables three-sided processing of a profile in just one clamping operation.

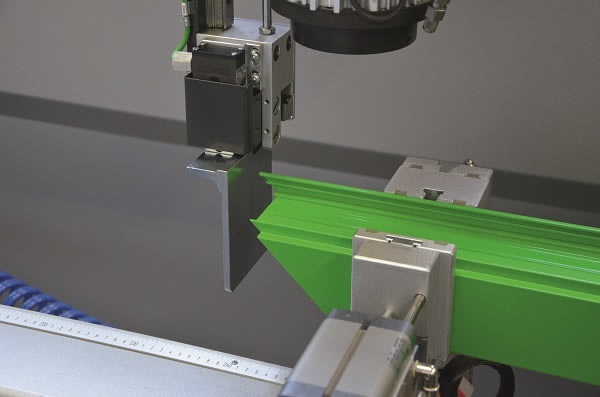

To this end, the powerful 8.5 kW spindle which is cooled with compressed air generates a torque of 13.5 Nm with a speed of up to 24,000 rpm. The profile length measuring device guarantees precise positioning of the machining and with length tolerances the processing is adjusted automatically in the SchüCam control software.

8.5 kW spindle

Furthermore, the tool magazine with ten tool positions has been designed in such a way that two side milling cutters can be stocked at the same time. The redesigned two-level clamping area (first level to 230 mm, second level to 300 mm) of the five motorised clamps allows a triple-track sliding unit from the ASS 77.HI series to be clamped.

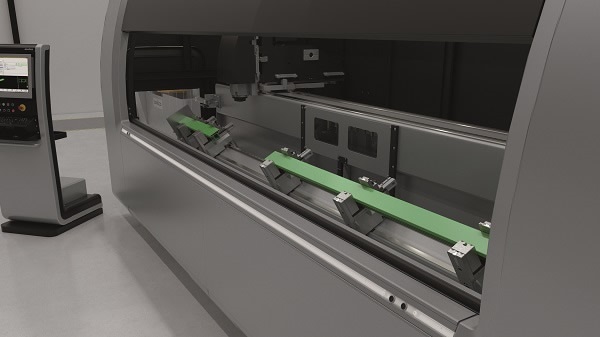

The high processing speed of the X axis (150 m/min) reduces distribution time to a minimum. In addition to the many processing options, the 30° insertion position of the Schüco AF 310 enables ergonomic work and a clear view of the clamping position.

Profile length measuring device

The clearly laid-out control panel ensures simple operation and optimum control. The machine status is also shown at all times by means of an illuminated LED strip. The processing data for the Schüco AF 310 can be generated directly in SchüCal and then transferred by USB or via a network.

30° insertion position

Menu-driven manual programming is also possible. Furthermore, the software uses optimisation algorithms that automatically calculate the most effective processing sequences.

For more information about Schüco machinery, visit www.schueco.de/machinery.

Two-level clamping area allows a triple-track sliding unit from the ASS 70.HI series to be clamped.

600450

600450

Add new comment