Date: 22 September 2001

Manufacturers and processors from the EU region have also cooperated.

These safety requirements will form and influence internal equipment strongly in the next few years. Therefore we can only recommend every user to have a quick yet thorough look at this draft in order to raise any necessary objections before the final standard passes. As already done in the past, we can only appeal again and again to the small and mid-sized factories to cooperate with these important safety requirements before they are caught by surprize by these standards.

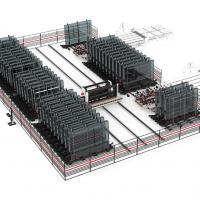

For the German glass industry, a vacuum lifting device was developed which partially meets the requirements of the draft prEn 13035-1. This is a device with a separate vacuum generation for the glass storage. For vacuum generation a vacuum pump is built into the craneway. The actual carrying frame with the suction cups (also called frame) was extended via a 2-circuit-system with a pressure differential. The vacuum supply from the vacuum pump in the craneway works via a hose winder.

Directly at the frame, the 1-circuit-system becomes a 2-circuit-system, i. e. there are two independent vacuum circuits. If one circuit should become unsealed, for example via a glass crack, the second vacuum circuit is then able to hold the stated transport weight safely. Each vacuum circuit has its own vacuum control device. If one circuit should become unsealed, the warning device will of course be activated. For the additional protection of the operator a grate is provided. The guide handles are mounted height-adjustable.

As also thin glass will be transported with this device, a vacuum reduction was built into each circuit. This enables one to adjust to a lower partial vacuum when thin glass sheets are to be moved. With this device it is possible to transport 2 mm to 19 mm thick glass sheets.

Add new comment