Date: 14 January 2019

A growing family contract glazing business is the most recent addition to the companies who can proudly note they are certified by the North American Contractor Certification (NACC) program. Forno Enterprises Inc. of Trout Creek, New York, completed the process and to get insight on how it all came about as well as some details about the organization we caught up with Brian Albanese, Vice President of Forno. Below Brian shares the background of the company, favorite installation, worries, and his thoughts on the NACC process overall.

NACC: I saw on your website that you have quite a few very experienced employees there- to me that speaks to the culture and approach of Forno Enterprises. What are some of the things that you do that make working at Forno so special?

Brian Albanese (BA): Our company has always had a family oriented and team approach atmosphere. The company was started in 1988 by my dad, Michael Spaccaforno. We have grown together under his leadership, our captain and mentor! He taught me how to lead by example and appreciate the hard work of each person on our team. When you have a company that people are proud to be a part of, they work hard to be successful each day.

NACC: With the wide range of products and services you offer, how do you and your team keep that all straight?

BA: Team Forno prides itself in being a custom products company, we are not your typical cookie cutter contractor. We are always exploring new products and means of execution. However, our growth has been slow and steady over the past 30 years with simple and straight forward policy, that there are procedures and forms, that are strictly adhered to, from the moment a contract is signed, until the fabricated product is installed in the field! Organization and compliance are key results to any company’s success story!

NACC: What is your all time favorite installation and why?

BA: Personally my favorite project was the College of New Rochelle in 2007. The project was very complex, but it was also very personal to myself in the transition of leadership. This project was the pivotal point of going from a “kid around the shop” to the company Vice President. The project was behind schedule, our manpower was limited, and we were entering a meeting with the general contractor to layout a game plan to recover the schedule. As the meeting started, my father got up from the meeting, stated he needed to use the bathroom and never returned. He left me in a sink or swim moment to become the project manager with no warning! From that moment, I worked my hardest every day to be successful! When I look back at the pictures of the finished project, it reminds me of that day and the confidence he had in me all along!

NACC: What’s the biggest business challenge you face today?

BA: The instant gratification complex that is a growing problem in all of society. We all want things now! As a result, the project schedules are very tight with shrinking budgets. People no longer have the patience to follow the correct steps of construction, and as a result, many buildings suffer long term problems.

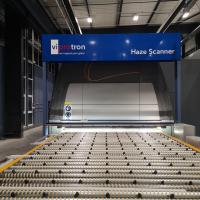

NACC: What the most positive change you have seen in the glass and glazing industry from when you started until now?

BA: Cell phone technology and the ability to communicate at a moment’s notice. The use of pictures and video chat allows me to sit at my desk and see the construction problems in real time. Down time during installation is a costly burden and that we can never avoid, but do our best to resolve as fast as possible.

NACC: Why did you decide to pursue NACC certification?

BA: I always knew, that Forno Enterprises, Inc. exceeded quality and workmanship, well above and beyond, our competitors. To be certified and recognized, on a national basis, against our peers, gives Forno Enterprises, Inc., the edge and distinction, that makes us stand out against other Glazing Contractors!

NACC: How did the preparation for certification change or improve your company processes?

BF: The Certification process has made Forno review and revitalize our existing guidelines and documents, in an attempt to ensure that Forno stays a predominant leader in our Field!

NACC: Was there anything in the process that surprised you? If so what?

BA: No, was not really surprised, by the process, but was impressed with the length of time, that was taken, with each of our Department Heads, learning all about their individual processes and being educated on any enhancements that would support our operation!

NACC: How will the certification help you with future bids or proposals?

BA: I think, that being certified, will keep Team Forno striving to be one of the most successful Glazing Contractors in the State of New York!

NACC: Now that you are done with the certification process are you pleased to have gone through it and would you recommend to others?

BA: I am extremely satisfied with the certification process, and would highly recommend it to any company, who is striving to be one of the tops leaders in their industry!

For more information:

Forno Enterprises: http://www.fornoenterprises.com

600450

600450

This recognition is a testament to their commitment to culinary excellence and adherence to industry standards. It's a well-deserved accomplishment that underscores their dedication to quality and professionalism in the culinary world. Elevate Enterprises, LLC Well done!