Date: 10 September 2014

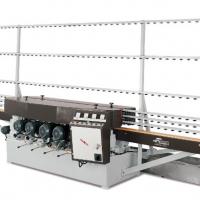

In detail:EDGING MACHINESTLS 15 AV C PC SP100 - Electronic straight-line edging machine for the processing of flat edge with arris and with variable angle from 0 up to 45° in a single passage, polished by liquid cerium oxide.

Equipped with a PC for all working phases management, it can carry a weight on the conveyor up to 1.100 Kg (2.200 Kg total on the whole machine) and process thicknesses up to 100 mm and with a size up to 12 x 3,21 mt.

We are proud to say that we are the only one able to vertical grind glasses with a 100 mm thickness.

Furthermore to this model will be joined a light bridge crane with suction cups for the handling of the glass sheets processed by the machine: live demonstrations will be performed every day!

TLR 11 AV C - Electronic straight-line edging machine with variable angle from 0 up to 45°, polished by liquid cerium oxide.

This model is part of the TLR series, which is the most used by the major producers of stratified glass for the heavy building industry in Northern Europe, is addressed to all glaziers with huge production of glasses with big sizes and great thicknesses.

TL 11 C - Electronic straight-line edging machine for the processing of flat edge with arris, polished by liquid cerium oxide.

Recommended for big productions of tempered glasses and/or high quality glasses for the interior design. It is able to process both glasses with important thicknesses and small glass stripes, up to a minimum size of height 35 mm.

AL 9 M AV - Electronic straight-line edging machine with variable angle from 0 up to 45°, polished by cerium oxide.

The AL m series machines can handle high production levels, being conceived and realized using some of the same technical solutions adopted for the edging machines of the major series, like for instance the assembling of the same spindles and the same conveyor. These details help to increase their lifetime, reducing at the same time the maintenance required.

Electronic straight-line edging machine with variable angle, model TLR 13 AV C

BEVELLING MACHINES

GAMMA 8 PC

Straight-line bevelling machine for the processing of the bevel polished by liquid cerium oxide, PC version.

It can process also small glass pieces.

Straight-line bevelling machine with PC

CORNERS GRINDING MACHINES

DELTA M5 C

Automatic corners grinding machine for the processing of radium and straight corners perfectly polished in a single passage with flat edge with arris, pencil edge and other profiles (according to the wheels that are fitted on).

Equipped also with liquid cerium oxide system.

VERTICAL WASHING MACHINES

OT 2000/400/4S - Open top vertical washing and drying machine for glasses with a thickness from 3 up to 20 mm (on request up to 40 mm) and with minimum dimensions of 350 mm.

The regulation both of the speed and of the glass thickness are motorized, in order to guarantee a high washing quality on each thickness.

All our washing machines can be integrated with vertical CNC machines as well as included in our edging and bevelling lines, also thanks to the possibility to have the work surface at the same height. On request it is possible to manage thickness and speed adjustments ‘in-line’.

We wait for you from 21st to 24th October at our Booth 16D38, Pavilion 16.

.jpg)

.jpg)

Add new comment