Date: 15 May 2017

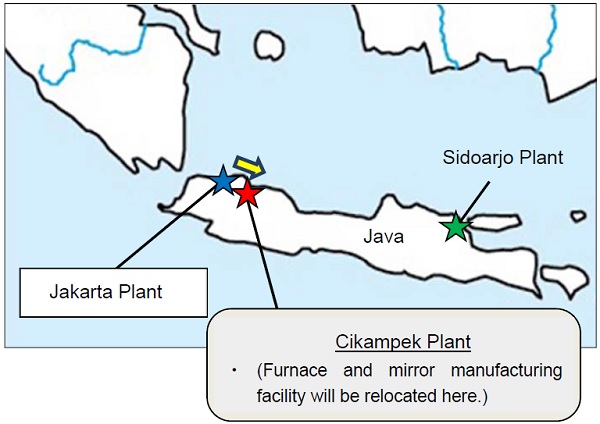

AGC Asahi Glass (AGC), a world-leading manufacturer of glass, chemicals and high-tech materials, announces that it will invest approximately 19 billion yen to relocate a float furnace and mirror manufacturing facility from the Jakarta Plant to the Cikampek Plant of PT Asahimas Flat Glass, Tbk (AMG).

The float furnace is for manufacturing of architectural glass and mass production is scheduled to commence in the first quarter of 2019.

The new float furnace and mirror manufacturing facility will have increased production capacity by 40% and 30% respectively, which will significantly enhance AMG’s architectural glass production.

AMG’s Jakarta Plant has been manufacturing flat glass since 1973. Under the Jakarta City Master Plan, the plant is facing relocation as the land category of the plant premises will be changed from industrial to commercial use.

One of the two float furnaces at the plant has already been transferred to the Cikampek Plant and started operation in

December 2016.

In anticipation of continued growth in Indonesia and Southeast Asia, the new furnace will be relocated with increased

production capacity as well as excellent productivity for high-quality glass.

Furthermore, AMG will enhance the production capacity for mirrors and other glass products for interior use to meet diversifying high value-added glass needs. Following the relocation, AMG’s Jakarta Plant will cease all production activities, and property will be sold.

Overview of the new furnace

1. Location: Cikampek, West Java, Indonesia

2. Production capacity: Approx. 210,000 tons of float glass per year

3. Special features:

a) 40% production capacity increase over the existing furnace

b) Environmentally friendly, fuel efficient furnace

c) Produces high-quality glass for various size and architectural usage

d) Enables efficient integrated production in conjunction with the adjacent mirror manufacturing facility and glass offline coating facility

Under its management policy, AGC plus, the AGC Group will continue to capture growing demand in Indonesia and Southeast Asia through the production enhancement in the region.

Furthermore, the Group aims to strengthen and solidify its growth foundations by responding to growing energy-saving needs in the area, which will be achieved by utilizing the offline sputtering coating facility that will start operation at the Cikampek Plant in the second quarter of 2018.

Reference

Overview of AMG

1.Company name: PT Asahimas Flat Glass, Tbk

2.Representative: Takeo Takei

3.Location: Jakarta, Indonesia

4.Capital: 217 billion rupiah

5.Investment ratio: AGC 43.86% (AMG is a consolidated subsidiary of AGC), Rodamas* 40.96%, Others 15.18%

* AGC’s local partner

6.Establishment: 1971

7.Products: Architectural glass, raw and fabricated glass for automotive use, industrial glass, mirrors

8.Production capacity: Float glass: 720,000 tons/ year (scheduled from the first quarter of 2019)

Mirror facility: 6.8million m2/ year (scheduled from the first quarter of 2019)

Offline coating facility: 6.0 million m2/ year (scheduled from the first quarter of 2019)

9.Production bases:

600450

600450

Add new comment