Others also read

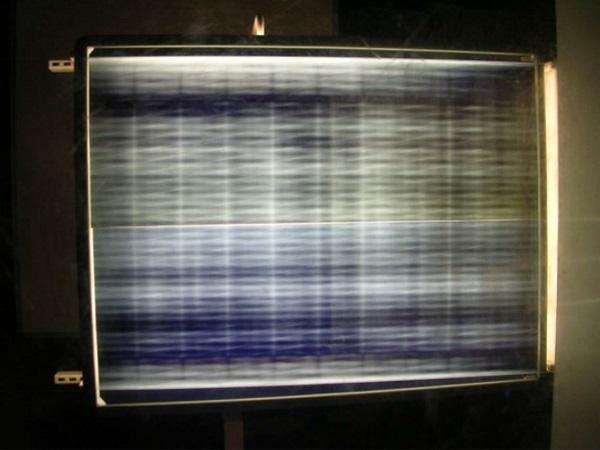

| Irregularities in the glass, which are visible under certain lighting conditions and interfere with the overall impression of a pane – anisotropies – occur when glass is tempered.

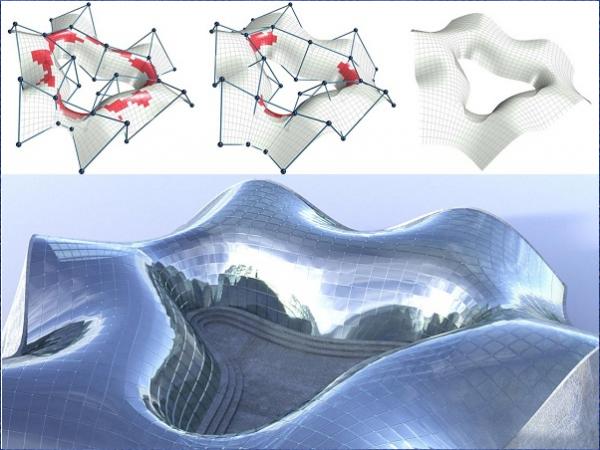

| Computer scientists develop a design tool that opens up the use of a cost-efficient technology for curved glass panels. The tool is based on a deep neural network and allows for the free-form design of beautiful glass façades.

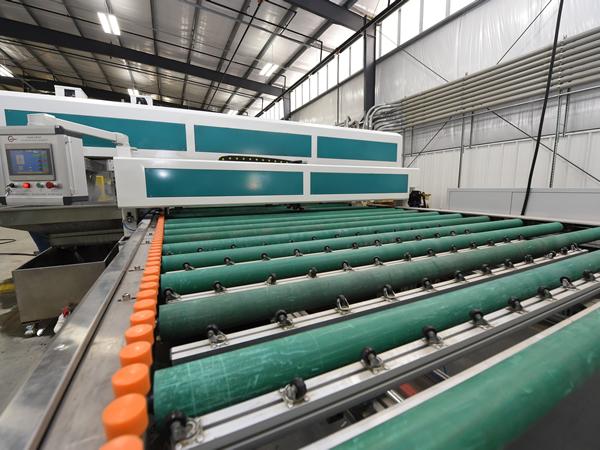

| Glaston is working hard to make tempering furnaces more automated.

| The new LiSEC glass edge deletion machines are equipped with improved sensor technology. This measures with greater precision and therefore guarantees constantly high finishing quality of the glass edges.

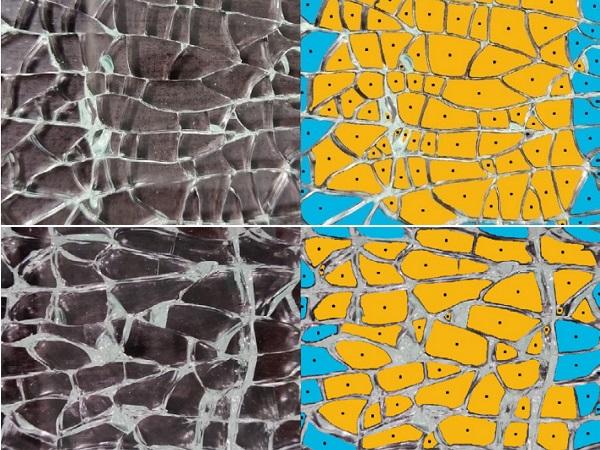

| It is a very known behavior that the glass fragmentation depends on where you break the glass.

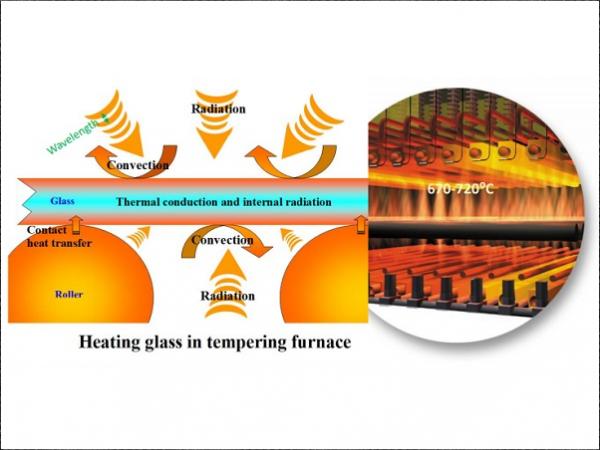

| In this paper, the basics of the heat flux modes are given, a solution method for the glass energy equation is introduced, and some tempering furnaces are theoretically studied to show the portions of the heat transfer phenomena inside furnaces during heating.

| In this paper local heat transfer of impinging small jets on surface heat transfer and residual stresses is studied.

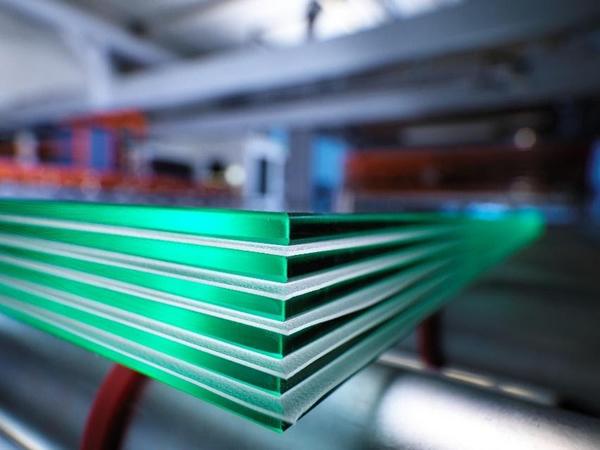

| Safety standards are constantly rising in all possible areas in which glass is used or installed – which is the reason why lamination is also becoming increasingly important in the glass industry.

| During times when the number of suppliers in all industries is steadily increasing and the market is becoming more and more transparent at the same time, the importance of cost-effective production for higher profit margins increases tremendously.

| It is well known that laminated safety glass (LSG) is a material that is specifically processed because of its composition.

| The fragment count in the standardized fragmentation test in the standard EN 12150-1 is the way to define the safety level of tempered glass and a way to also get an indication about the stress and strength level of the tempered glass.

| The author proposes a simple surface quality test using a standard window cleaning scraper and common smartphone or shop microscope.

| This article will focus on the edge stability of PVB and ionoplast laminates and address the potential causes of blemishes.

Glass off the roll - Thin glass is revolutionising the performance spectrum of glass and glass panes

| Thin glass – as thin as a razor blade or a human hair – is a reliable method to protect smartphone touchscreens, sensitive filters and sensors.

| Learn about the first step we take in maintaining tempered glass quality standards.

What do power consumption, installed power and installed capacity of a glass tempering furnace mean?

| Power consumption of the glass tempering furnace refers to the amount of electric energy consumed in the process of tempering certain quantity of glass. The measuring unit commonly used is the kilowatt hour (KWh).

| We’ll help you meet the spec with our knowledge of the glass tempering process.

| Keeping impurities away from the glass is imperative in the glass tempering process. These impurities can cause damage resulting in a product that doesn’t live up to aesthetic standards, won’t meet a client specification or is completely unusable.

| sedak GmbH & Co.KG, Germany, operates the largest insulating glass line in the world – about extraordinary glass processing and the role of LiSEC.

| LiSEC is the pioneer in terms of the development and production of production lines for large-scale insulating glasses – incl. interview with Hannes Spiss, facade engineer at Arup, Büro für Bautechnik (office for construction technology)

| Skaala was founded in 1956 as a one-man company. The father of the two current owners, Hannu and Markku Hautanen, was a carpenter and already in those days, he processed glass while repairing doors and windows.

| glassonweb.com contacted the major players in the flat glass industry, asking for their statements regarding the Brexit vote results and how they see it affecting the near future of the European glass and construction markets.

| Cost cutting, it is often said, is difficult in glass production and processing as this sector is characterised by manual processes.

| In August 2013, the LiSEC development team started a major project with the mission: redesign of the tempering furnaces in order to save manufacturing costs and at the same time increase the process reliability. Result: the AEROFLAT.

| “Thank you for all the services your company has provided for us. We really appreciate all, the great installation and startup of the RC200™. We are very happy with the outcome of our new furnace.”

![Tempered Glass Specifications [Video & Transcript] Tempered Glass Specifications [Video & Transcript]](/sites/default/files/styles/6/public/articles/2017/HHH-Tempering.jpg?itok=P7frNEF5)