Others also read

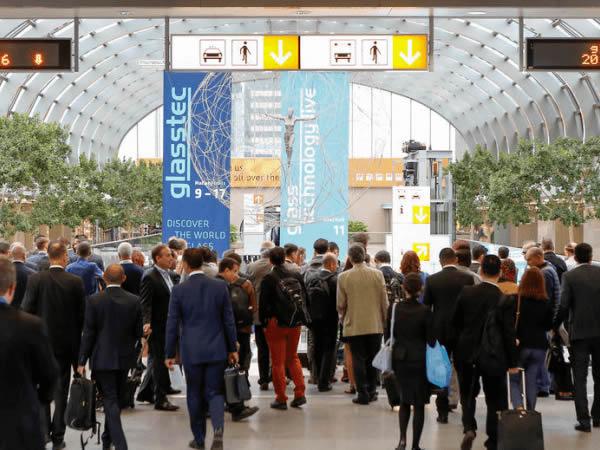

| glasstec generates important impulses: Good mood and solid investment climate

| Also, this edition confirmed glasstec as the main glass industry event. Check out the highlights from the show.

| Thanks to the committed involvement of architectural offices, university departments and industry associations, glasstec offers some unique added value: the special show: glass technology live!

| sedak GmbH & Co.KG, Germany, operates the largest insulating glass line in the world – about extraordinary glass processing and the role of LiSEC.

| LiSEC is the pioneer in terms of the development and production of production lines for large-scale insulating glasses – incl. interview with Hannes Spiss, facade engineer at Arup, Büro für Bautechnik (office for construction technology)

| The innovative FINSTRAL window wall system meets demanding requirements – constantly flexible, always individual

| Skaala was founded in 1956 as a one-man company. The father of the two current owners, Hannu and Markku Hautanen, was a carpenter and already in those days, he processed glass while repairing doors and windows.

| Cost cutting, it is often said, is difficult in glass production and processing as this sector is characterised by manual processes.

| Today’s functional buildings tend to have shapes that go much further than pure expediency, and glass is therefore used more and more frequently as a structural support element.

| In August 2013, the LiSEC development team started a major project with the mission: redesign of the tempering furnaces in order to save manufacturing costs and at the same time increase the process reliability. Result: the AEROFLAT.

| “Thank you for all the services your company has provided for us. We really appreciate all, the great installation and startup of the RC200™. We are very happy with the outcome of our new furnace.”

| Touchscreen displays, LED technology and ultra-thin glasses: The multifunctional diversity of glass in IT and architecture will, in the long term, lead to a combination of both.

| Furnaces are currently inspected on a regular basis with thermal imaging sensors and other techniques that heavily rely on experience of the plant personnel.

| Modern, transparent and prestigious – large glass façades are very much in vogue for office complexes and industrial buildings.

| “UniGlass is committed to stay at the forefront of the technological trends. We want to make sure we can offer our customers the total range of glass products that they need for their projects.”

| For the past five years, Nile Aluminium & Metals Company, or AluNile, has had very positive experiences with Glaston's first FC500™ tempering furnace sold outside Finland.

| Being highly focused on flat glass processes for partitioning used in the office industry, Tufwell Glass Ltd has carved out a unique and resilient position for itself in southeast region of England.

| After 10 years of experience with the Glaston HTF 2142 furnace, Paul Buckley, Managing Director of the PJB Glass Group, decided to complement his flat glass production offering by investing in a Glaston RC200™ furnace.

| The Flachglas Group employs around 1,100 employees at three sites in Switzerland and three sites in Germany – around 650 of them generate revenues of approx. € 70 million at the Wernberg site (Bavaria).

| Sanshiba Shozai of Japan chose to be the first glass processor in the world to invest in Glaston’s latest GlastonInsight™,the intelligent online assistance system, at the same time as it ordered the Glaston RC350™ tempering furnace.

| Over half the world’s seven billion inhabitants live in cities, by the year 2050 the number will grow to almost ten billion. In order to avoid a climatic collapse in the metropolises, there is no other alternative to energy-efficient buildings.

| In just two and a half decades glass has very quickly made the transformation from simple window glass to an almost universally applicable material.

| Cities are eating up an increasing amount of heat and electricity. In order to reduce this consumption, buildings have to become increasingly efficient and integrate more renewable energies.