Date: 25 September 2014

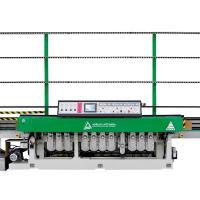

From the most basic model, with manual speed change and thickness from 3 up to 15 mm, to the most important one with motorized regulation both of the speed and the glass thickness, and possibility to process glasses up to 3300 mm and thicknesses up to 40 mm.Washing machine model OT 1600/400/4S in line with our edging machine model TL 11 AVAll our washing machines can be integrated with vertical CNC machines as well as included in our edging and bevelling lines, also thanks to the possibility to have the working surface at the same height.On request it is possible to manage thickness and speed adjustments ‘in-line’.

.jpg)

Washing machine model OT 1600/200/4S

.jpg)

Washing machine model OT 2000/400/4S

Here-after some of their main features:

- The body of the machine and all the parts in contact with the water are made of stainless steel while an anti-corrosion covering is granted by the use of epoxy and polyurethane paints.

- The machines are composed of two different washing sections, equipped in total with 4 or 6 brushes, which can also be available in a special version for low-e coated glasses.

- In the first section hot water can be also required.

- The drying is done by a couple of blowers powered by a

high-pressure soundproof ventilator. - The inlet and outlet conveyors are motorized like the glass thickness adjustment, guaranteeing this way a better washing quality on every thickness.

- On the conveyors it is also possible to have belts instead of the standard rolls: the advantage is to help the operator while loading/unloading both small and rounded/shaped glasses.

- On the outlet side as an option it is possible to have a black panel with inspection lamps, to facilitate the control of the cleanliness degree of the glass sheet.

- As an additional safety, the washing machines can be equipped with a sensor, positioned on the outlet conveyor and connected to an acoustic alarm. Its function is to detect the presence of the glass sheet at the end of the rack.

- In order to obtain energy saving, they can also be equipped with an additional sensor, positioned on the inlet conveyor, which detects the presence of the glass sheet at the entrance side of the machine and reactivates some functions in stand-by mode.

.jpg)

Washing machine model OT 3300/800/4S

Add new comment