Date: 2 September 2025

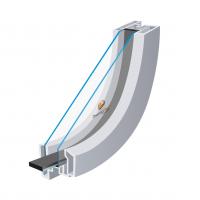

It comes as the industry is under pressure to deliver IGUs that meet stricter energy efficiency standards, driving demand for warm-edge technologies that enhance thermal performance and meet sustainability targets.

July’s production milestone follows a period of significant investment in machinery by Thermoseal Group, as well as increased production runs to produce a wider range of spacer bar thicknesses to meet both international and domestic market demands.

“Increasing production capacity for Thermoflex allows us to be responsible to the needs of our customers at home and abroad”, said Mark Hickox, Sales Director at Thermoseal Group. “We’ve invested heavily in our UK manufacturing, technical expertise, and testing facilities to deliver consistently high-quality products which are supported by our excellent customer service.”

Thermoflex, internationally recognised and certified by IFT Rosenheim as the best performing flexible silicone spacer bar in the world and approved by the British Fenestration Rating Council (BFRC), is manufactured at Thermoseal’s state-of-the-art manufacturing facility in Wigan.

Also present at the plant is a fully equipped EN1279 lab, which integrates in-house testing with rigorous product development and quality assurance, ensuring that every product manufactured by the component supplier is fit for purpose and exceeds relevant standards.

“Demand for warm-edge spacer bars is rising on a global scale, and thanks to our recent investments, we are in a strong position to supply both the UK and International markets,” added Mark Hickox. “Our commitment to innovation and quality is what sets Thermoflex, Thermobar, and our entire range ahead of the game”.

For more information, please visit www.thermosealgroup.com, or call 0121 331 3955.

600450

600450

Add new comment