Date: 7 July 2025

“20mm spacer bars have long been the UK’s most widely used airspace, accounting for around 80% of units,” explained Mark Hickox, Sales Director at Thermoseal Group. “However, tighter u-value targets, increased specification of laminated glass for Document Q compliance, and increased usage of triple glazing are all reshaping this landscape.”

As laminated glass typically increases the overall thickness of the glass within the unit, to maintain the required overall thickness, manufacturers are now having to reduce spacer width by around 2mm - with the most common sizes now erring towards 14mm, 16mm or 18mm, according to Mark.

And in triple glazing, the change is reported to be equally as significant.

“Traditionally, manufacturers combined multiple spacer sizes, such as 8mm bars, to arrive at a 28mm triple glazed unit, which would fit in standard window frames”, explained Mark. “However as more ‘European type profile systems’ are entering the market, it’s becoming more common to see sealed units with a total thickness of 36mm, 44mm or even 52mm!

“This has also led to increased specifying of larger air spaces, such as 22mm or 24mm, combined with more commonly used smaller sizes.”

Thermoseal Group has closely monitored this trend through detailed order analysis and customer insight. In response, it has implemented a flexible, campaign-based production approach across its five UK-based spacer bar lines.

This enables consistent high-volume output of core sizes like 20mm, while seamlessly introducing production runs of 14mm, 16mm, 18mm, 22mm and 24mm as needed.

“We’re not just watching these changes - we’re engineering our operations around them,” said Mark. “By leveraging our production capacity and in-house tool design, we can rapidly pivot without compromising lead times or stock availability for our customers.”

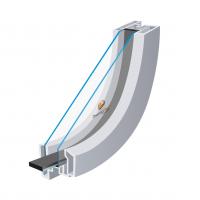

This responsiveness is complemented by Thermoseal’s high-performance warm edge products. Thermobar, a rigid tube spacer, and Thermoflex, a premium silicone foam option, are both designed for enhanced thermal performance.

Thermoflex also leads the global market for flexible spacers with a thermal conductivity of just 0.125W/(mK), certified by IFT Rosenheim and BFRC-approved.

“As the Future Homes Standard approaches, precise u-value calculation is vital,” Mark added. “Choosing high-performance spacers like Thermoflex and Thermobar helps our customers meet specifications and avoid costly recalculations.”

For more information, please visit www.thermosealgroup.com, or call 0121 331 3955.

Add new comment