Latest news

220 results

| Experience the wonder of glass architecture with ESD Systeemwanden and quality assured by Viprotron ECO Scanner.

| After weeks of work and dedication, LiteSentry and Softsolution present their new website.

| For several months Viprotron has been working in secret on an important project. And now it is live!

| See the most advanced metrology technology at the Softsolution – LiteSentry booth, at Vitrum in Milan.

| LiteSentry-SoftSolution are excited to be showcasing at Glasstech Mexico November 30th-December 2nd!

| Here are some signs, where support comes from using Viprotron scanners.

| Complete metrology scanner after furnace exit: Rollerwave, Edge Kink, Anisotropy, White Haze, Scratches and Coating defects.

| Great interest in Viprotron's latest innovation, the Temper Scanner 5D.

| Visit Litesentry-Softsolution team in booth 7104 to chat with their team and learn more about their company.

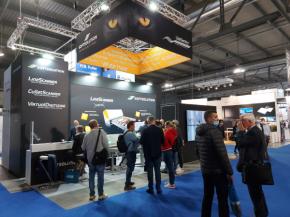

| This year was marked by the joint appearance of Softsolution and Litesentry, presenting both companies and products at one booth.

| Sparklike is exhibiting in Glasstec 2022 on the 20th – 23rd of September in Düsseldorf. You can find them in Hall 14 Stand G17.

| Tristar now has LiteSentry inspection systems on all 7 of their furnaces.

| Featuring the only optical technology that measures all forms of distortion.

| Viprotron team will present their highly advanced glass scanning solutions at glasstec 2022.

| Softsolution produces unique LineScanners at the highest technical level.

| Below are just some of Glaston's latest developments that will be showcased to the participants at this year’s glasstec 2022.

| FAKRO in Poland takes their Insulating Glass quality to the next level by measuring insulating gas concentration with the Sparklike Laser Portable 2.0.

| Where ultimate inspection technology is born - LiteSentry and SOFTSOLUTION are ONE company

| The Story of LineScanner installation for visual defect detection at the Home Appliance Division at SCHOTT Flat Glass CR, in Valasske Mezirici, Czech Republic.