Others also read

The HUB is a central component of the global LiSEC strategy, with around a quarter of the world's population living in this region.

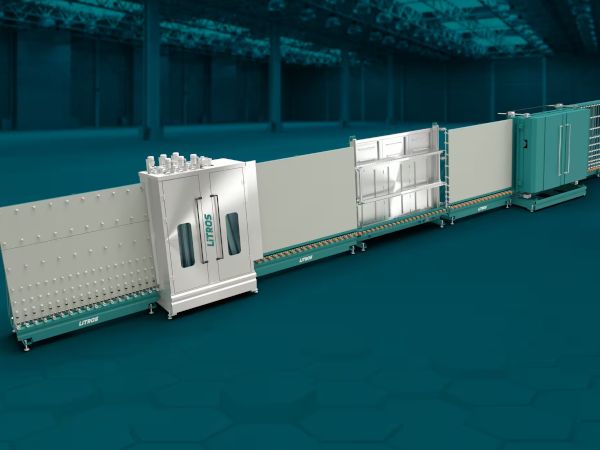

The vertical LiTROS insulating glass line offers a good solution for the efficient production of insulating glass units with rigid spacer frames.

At Fensterbau Frontale in Nuremberg, the HEGLA Group will be focusing on solutions for efficient storage and logistics of glass, windows and long goods profiles.

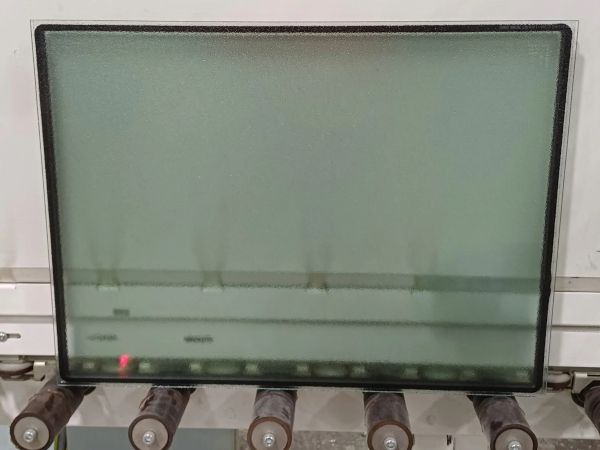

Xinruineng ensures compliance with China’s 85% argon requirement by using Sparklike’s non-destructive gas measurement technology to guarantee reliable energy performance in insulating glass units.

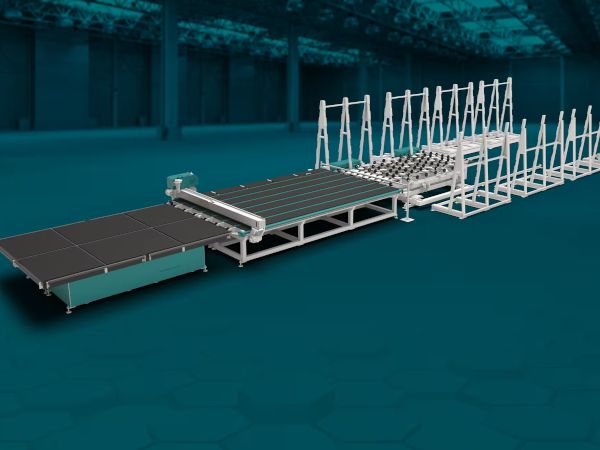

The LiTROS glass cutting line is a sophisticated, modular solution for industrial processing of float glass.

Knowing its roots helps shape the future. From Tamglass in the 1970s to Glaston today, the company’s windshield-bending journey has been driven by curiosity, craftsmanship and teamwork.

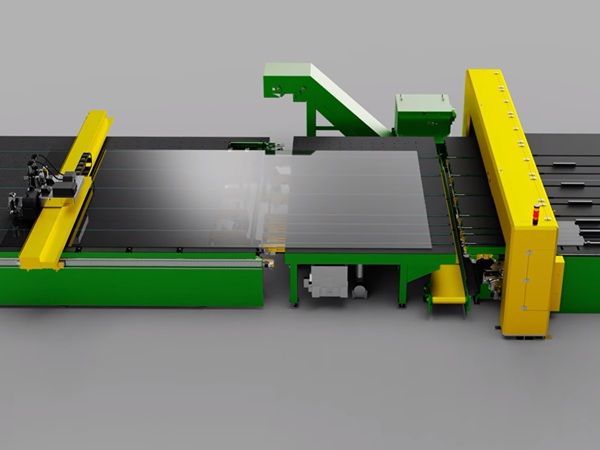

Hegla has released a new video showcasing the ProLam Neo LSR, its fully automated, high-performance cutting solution for laminated safety glass.

Kuraray’s Advanced Interlayer Solutions (AIS) Division is excited to announce the opening of a new office in Dubai.

TSS is not just technical support – it is a forward-looking partner for realising high performance production solutions.

Invisible Shield Easy-Clean Protective Coating/Shower Treatment. Seals glass against water stains.

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

Zero worries. Maximum productivity.

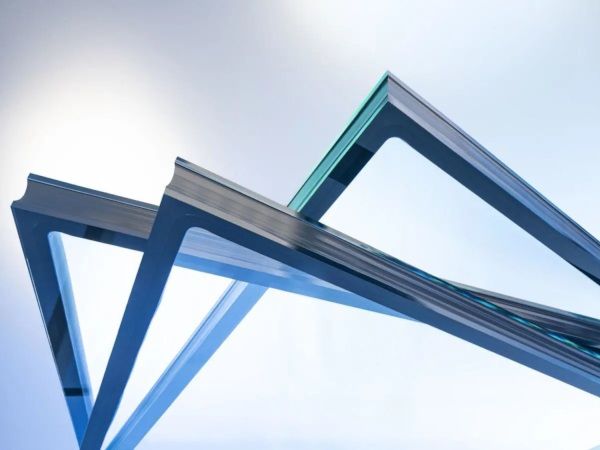

A smart solution for lighter, slimmer, and more efficient insulated glass units.

Kensington Glass builds smarter and more precisely by pairing craftsmanship with the power of A+W Software.

Chongzheng Shengda Glass opts for the first 8 × 3.3 metre TPA line from LiSEC.

The SplitFin is a vertical processing line for flat glass with two processing towers: EPS-B for edge processing and MRX-B for internal processing.

As customer expectations for energy efficiency and glazing performance continue to rise, SafeGuard Glazing Supplies has reinforced its commitment to quality with the Sparklike Laser Portable™ 2.2.

CMS aura is the vertical dry seaming machine designed for those seeking efficiency, simplicity, and savings in the glass processing workflow.

HEGLA-HANIC redefines how glass companies manage orders with an industry-specific Microsoft Copilot assistant.

Discover how the new Glaston TPS® PRO technology sets a new benchmark in insulating glass manufacturing.

A Transformative Leap in Automated Order Management for the Glass Industry

A forward-looking collaboration between NBS and Forel shows how automation and large-format glass production are redefining the future of industrial glass manufacturing in Japan.

Changing software is an opportunity to show how the right partner, process, and mindset can turn uncertainty into lasting growth.

Its recent investment in the innovative LiSEC SRP-A system underscores their shared commitment to digitalisation and greater efficiency.