Others also read

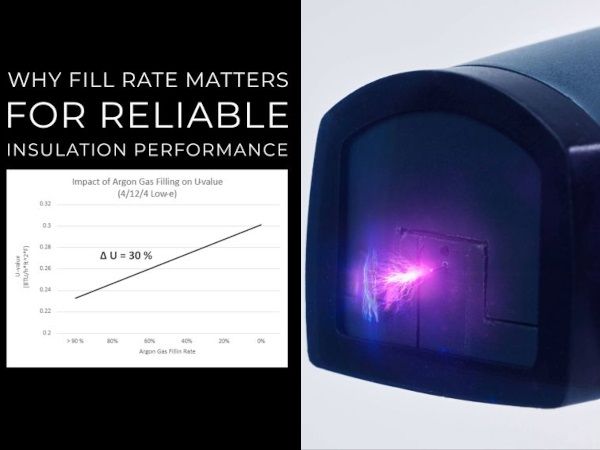

Making sure insulating glass units (IGUs) meet high standards is essential for both manufacturers and installers. The gas fill level in IGUs is key to providing good thermal performance and energy efficiency.

Glasstech Asia 2024 showcased glass industry innovations, with Elegant IG emphasizing quality and precision in insulating glass measurement as Sparklike's regional distributor.

The latest evaluation by ift Rosenheim confirms that the Sparklike Laser Portable 2.2™ meets the accuracy requirements of EN 1279-3 for measuring gas concentrations in insulating glass units (IGUs).

In the production and quality control of Insulating Glass Units (IGUs), maintaining consistent gas concentration readings is important to maintain its properties.

Vasglass continues to push the boundaries of quality and innovation. Here’s how they tackled a key challenge in insulating glass verification.

This article explores the importance of maintaining proper gas levels, the technology behind accurate measurements, and the impact on customer satisfaction and industry standards.

A recent evaluation by ift Rosenheim has validated the performance of the Sparklike Handheld 3.0™ for measuring gas concentration in insulating glass units (IGUs).

NSG Group is pleased to announce the warm up of a newly converted TCO (transparent conductive oxide) facility in the United States.

Sparklike is proud to celebrate a major milestone: the delivery of their 2000th Sparklike Handheld device to Insul-Lite Manufacturing.

When it comes to energy-efficient windows, the role of gas filling in insulating glass units (IGUs) cannot be overstated.

Longer lifetime, higher reliability

When it comes to ensuring the quality of insulating glass units (IGUs), accurate measurement of gas concentration is critical.

FREOR, a leader in energy-efficient refrigeration solutions, has implemented the Sparklike Laser Portable to ensure optimal argon levels in insulated glass units.

When comparing sealed units (insulating glass units, IGUs) with single-pane glass, several key performance metrics highlight the advantages of sealed units.

While some manufacturers prioritize the mere presence of gas, Sparklike aims to educate the industry on why the exact argon-filled units’ gas fill rate matters.

Sparklike is pleased to announce its partnership with Nex, a prominent Brazilian company specializing in intelligent solutions for vitreous systems.

BFRC adopts Sparklike Laser Portable™ 2.1, setting new standards in non-invasive gas measurement.

Join Optris for an exclusive event exploring the latest innovations in glass tempering technology. The event will take place on Thursday, October 24, at 4:30 p.m. in Hall 14, Booth F14, during Glasstec 2024.

The NSG Group announces that it has made the decision to cease production at one of its two float glass lines at Gladbeck, Germany, as from January 2025.

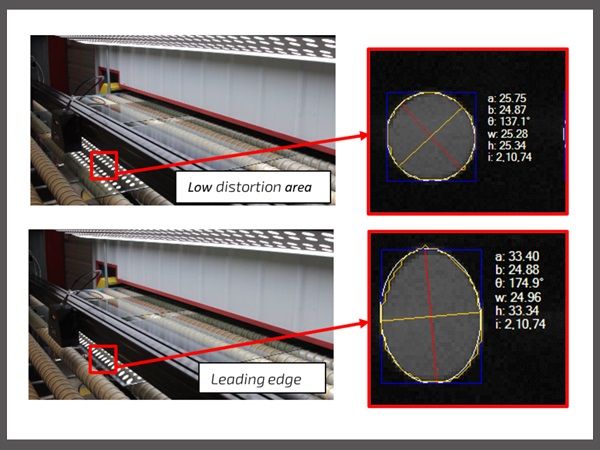

How Osprey is revolutionizing glass measurement to ensure maximum quality in your production process.

Experience the LiSEC ARL-45F frame filling machine with innovative measurement system and desiccant level indicator live at the glasstec exhibition in Düsseldorf at the LiSEC stand in Hall 17 / A64!

In the production of insulating glass units (IGUs), precise control over the gas filling process is critical to maintaining product performance.

The integration of Sparklike Laser Integrated into the insulating glass production line significantly enhances quality control and efficiency.

Recently, Sparklike provided specialized training to Jiacheng to help enhance the quality of their Insulating Glass Units (IGUs), focusing on customer-centric approaches to improve overall production standards.