Others also read

The time is drawing near: on Wednesday, BAU ONLINE will start with more than 230 exhibitors from 28 countries, offering over 1,300 live presentations and 3,500 one-on-one appointments.

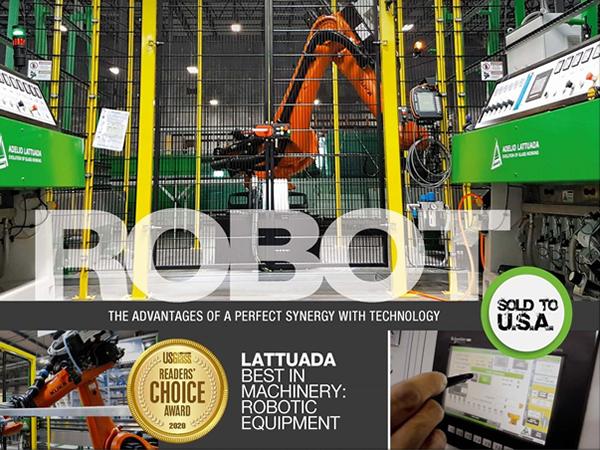

Adelio Lattuada & Lattuada North America won the 2020 edition of the USGlass Magazine® Reader's Choice Award for the 'Robotic Equipment' category.

Glaston Group has closed a deal for three insulating glass lines with one of the leading architectural glass suppliers in China, CSG Holding Ltd.

In this video the topic Software Data Transparency at LiSEC is clearly presented.

The Elb 9 + 2 is capable of producing a complex profile on the edge of the glass in a single pass without the need to process the glass on different machines or change setups.

Mappi International has won the 2020 USGlass Readers’Choice Award for Machinery - Tempering Equipment with Industry 4.0 Tempering solutions, now enhanced with “Powered by Siemens” improvements.

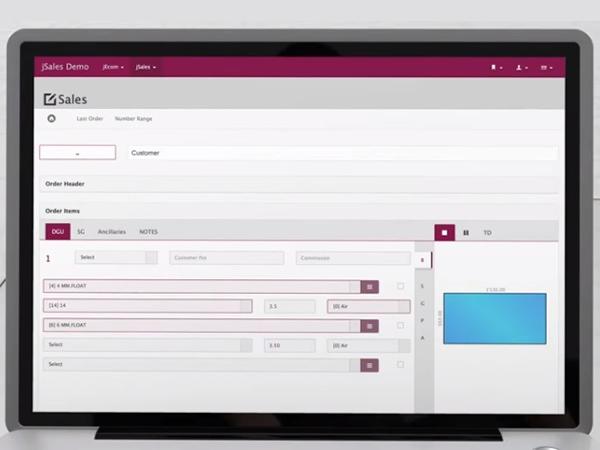

Integrated software solutions for the entire production chain are adapted for individual customer segments.

How can you prolong the lifetime of your equipment? Find out in LiSEC's new video!

The Rapidstore, as an automated storage system, simplifies manufacturing methods and gives business owners greater capacity.

The contribution of Bovone to the advancement of the glass industry towards the 4.0 horizon.

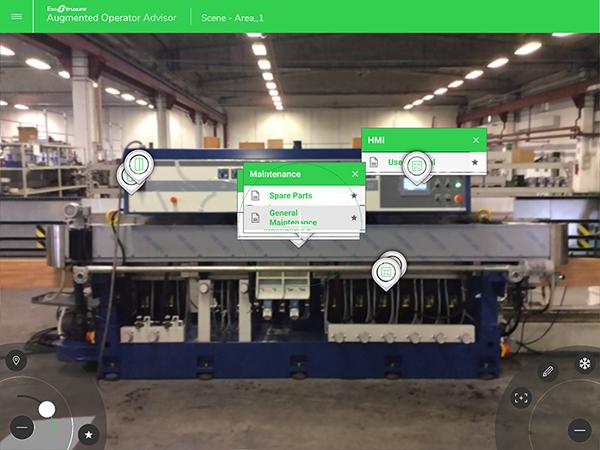

Industry 4.0, digitalization of processes, remote assistance: the levers of Bovone Group to enhance the business of its customers.

Federico Ratti, Innovations Director, sits on the committee, representing the global leader group in machines and industrial components.

How does LiSEC.eye work? What advantages does LiSERV offer? Answers to these questions and much more information can be found in the new video.

The process of affirmation of 4.0 technologies on the current industrial scenario saw a significant acceleration in 2020.

This presentation documents the proper handling methods and processing conditions for the lamination of SentryGlas® SG5000 and SentryGlas® Xtra™ (SGX™) SG6000 ionoplast interlayers.

With the LiSAIR Express Delivery Service you can receive spare parts faster and more easily than ever before, and with no potential transport problems. Traffic jams and roadworks literally vanish into thin air.

Gaining digital added value and simplifying workflows are the focus of the HEGLA Shop-Floor app, which is available in tablet and smartphone versions.

The acquisition of an insulating glass line in 2008 was the starting signal for the successful cooperation.

Without a digitizing solution, customer supplied templates can often be a difficult task, as the Swiss company FRANZ GYSI AG can confirm.

Glaston is launching its new brand to communicate the full strength of the new Glaston.

The LiSEC partners Schraml Glastechnik, Glastronic, Glastech and Cericom play an important role in the LiSEC "all in one solutions" philosophy.

More than 1000 visitors from right around the world took up their invitation to visit the virtual LiSEC trade fair that took place from 27 to 30 October 2020.

Work is changing for many different reasons and not just because of the pandemic. How can mobile applications help your workers do more in less time? How can they help you increase your yield or revenue?

In the LiSEC Management Panel Discussion, changes, developments, the virtual LiSEC Campus, and many other current topics are discussed.