Others also read

HORN® has started the furnace heat-up process at glass packaging supplier Frigoglass' 300 t/d end fired furnace GF2 in Nigeria.

Taiwan Tobacco & Liquor Corporation is the leading and largest tobacco and liquor company in Taiwan. The company has started construction of a new furnace in Taiwan.

As always, regardless of materials and production processes, creativity is what makes the difference. It is the “details” that determine a brand’s or product’s identity.

The JaBee Tower, which has been erected in the town of Dübendorf (Switzerland), is currently the highest residential building in Switzerland. It was designed by the Swiss company sattlerpartner architekten+planer.

In August 2020, the German glass plant manufacturer HORN® Glass Industries AG announced that with its new subsidiary in Brazil, the company is expanding its local availability in South America.

With Starphire® glass, you can express colors and patterns in their purest forms and evoke luxury anywhere from decorative murals to doors.

AGI glaspac has partnered with HORN Glass Industries AG of Germany to build a new furnace of 154 TPD at AGI Speciality Glass Division’s Bhongir plant in Telangana.

Yorglass Satin Range combines aesthetics with high quality

POLFLAM® BR fire-resistant bent glass, as well as our fire-resistant flat glass, were both used in the glazing for the BONARKA underground car park’s stunning entryway.

HORN® has started the furnace heat-up process at GCA's new 400 t/d end fired furnace in Turkey.

Developed by Şişecam Group, revolutionary V-Block Technology which prevents the growth of microorganisms on glass surfaces, is ready to go in to markets as the world’s first antimicrobial glassware.

Inside and out, interlayers from Trosifol prove their capabilities in structural and aesthetic applications... both sides of the Atlantic.

In 2020, the record number of 135 parcels from 2019 was exceeded by far. No less than 222 parcels were donated.

Şişecam begins producing the world's first antimicrobial glassware products that are also effective against coronavirus

Employees, customers and the company itself benefit from continuity in the company's workforce. This is especially true for the traditional company HORN® in Plößberg.

The existing furnace will be enlarged by HORN® and equipped with new heating equipment and safety control.

The entire construction and commissioning was supervised and managed by HORN®.

The glass panes are joined with fireproof silicone sealants and the resulting joints are only 2 mm wide. The pane edges are aesthetically finished with a strip of ceramic paint of appropriate width in any RAL colour.

Products by HORN® Glass Industries stand for quality and reliability. HORN® customers all over the world appreciate this claim.

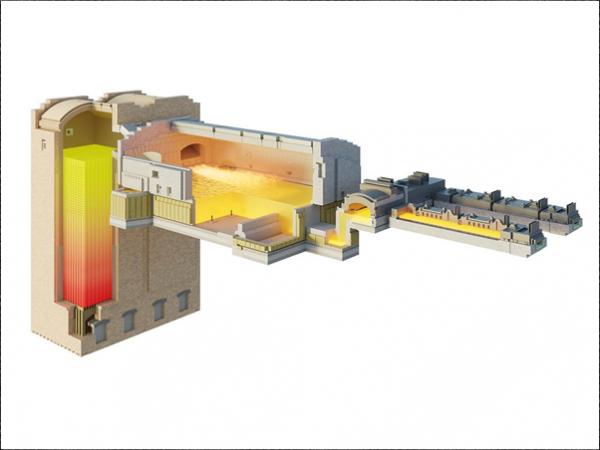

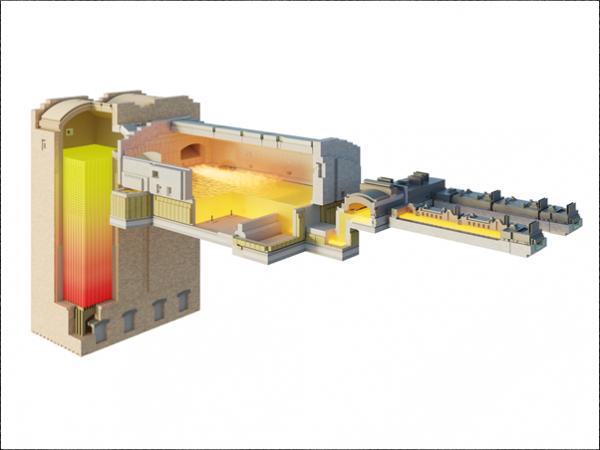

The furnace is designed in appliance with the most advanced technology and a maximum melting output of 290 t/d to produce either 290 t/d flint or amber glass or 280 t/d green glass.

The Liverpool City Region will benefit from £54 million investment to revitalise its glass industry and support the region’s economic recovery.

The awards, now in their seventh year, will take place this year virtually on 12 November and will again celebrate the achievements of the glass industry and its supply chain.

This innovative partnership will allow Eastman to satisfy the increasing demand for superior low-iron glass products.

HORN® Glass Industries will show you a film of how a glass melting plant grows, exhibit 24 products and support the technical lectures in the MELTING session on Tuesday, October 27, 2020 as sponsor.

The Belarusian company JSC "Grodno Glassworks" Elizovo Branch has appointed HORN® Glass Industries for the construction of a modern end fired furnace with a maximum capacity of 180 t/d.