Others also read

Xinruineng ensures compliance with China’s 85% argon requirement by using Sparklike’s non-destructive gas measurement technology to guarantee reliable energy performance in insulating glass units.

At Fensterbau Frontale in Nuremberg, the HEGLA Group will be focusing on solutions for efficient storage and logistics of glass, windows and long goods profiles.

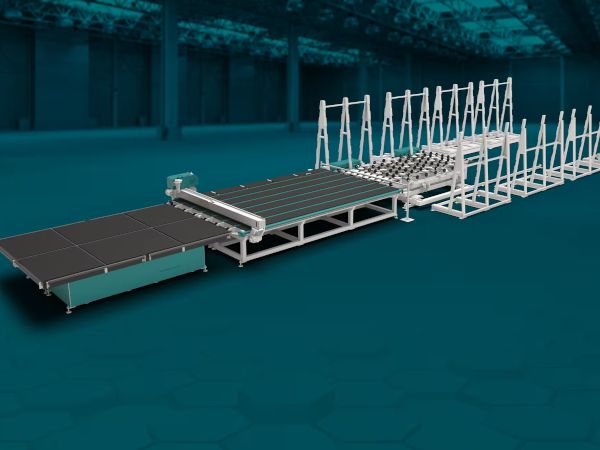

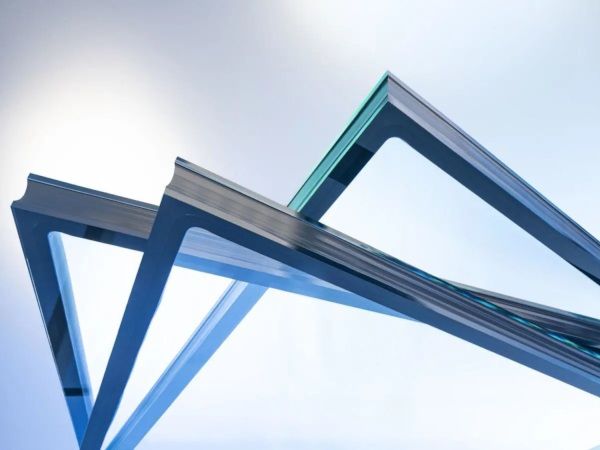

The LiTROS glass cutting line is a sophisticated, modular solution for industrial processing of float glass.

Thomas Claude Sauer, Managing Director of EXXOSQEL and glasstec 2024 speaker, explains how a novel surface treatment “heals” micro-cracks at a molecular level — a breakthrough for lightweight design and glass industry decarbonization.

Satinal announced the successful conclusion of its participation in Glass Expo Hawaii™, held from February 4–6 in Honolulu.

Knowing its roots helps shape the future. From Tamglass in the 1970s to Glaston today, the company’s windshield-bending journey has been driven by curiosity, craftsmanship and teamwork.

Şişecam to contribute to the circularity of electric vehicles with innovative glass solutions.

Apply now for the START-UP ZONE or the BMWE YOUNG INNOVATORS joint stand

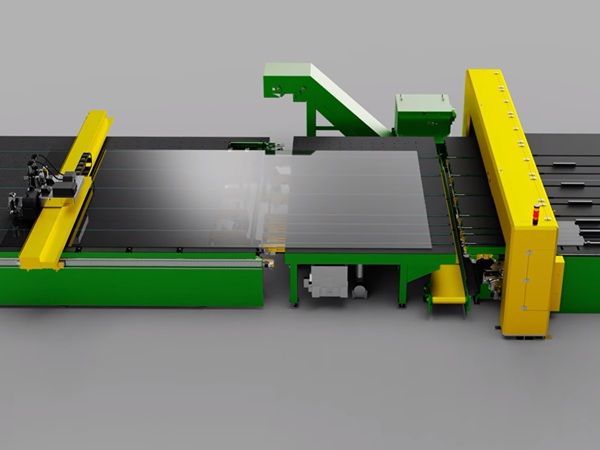

Hegla has released a new video showcasing the ProLam Neo LSR, its fully automated, high-performance cutting solution for laminated safety glass.

Kuraray’s Advanced Interlayer Solutions (AIS) Division is excited to announce the opening of a new office in Dubai.

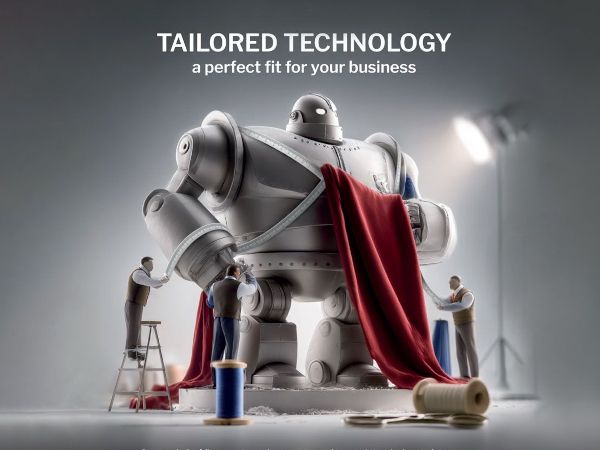

When we think about industrial technology, we often imagine standardised production lines, catalogues with predefined models, one-size-fits-all solutions. This is a logic that does not belong to SCHIATTI.

Invisible Shield Easy-Clean Protective Coating/Shower Treatment. Seals glass against water stains.

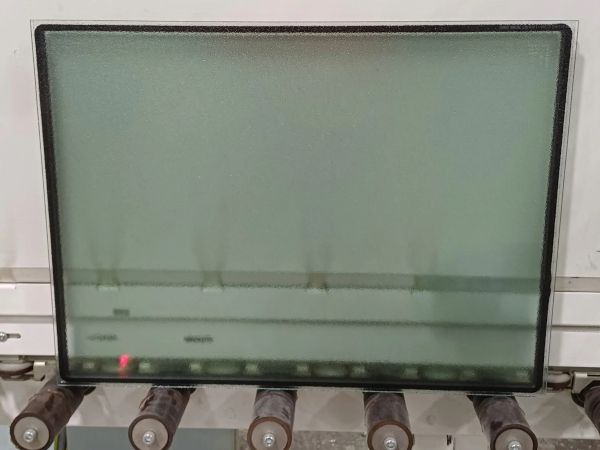

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

Zero worries. Maximum productivity.

Innovation meets opportunity. The Start-Up Zone at glasstec puts emerging glass technologies on a global stage.

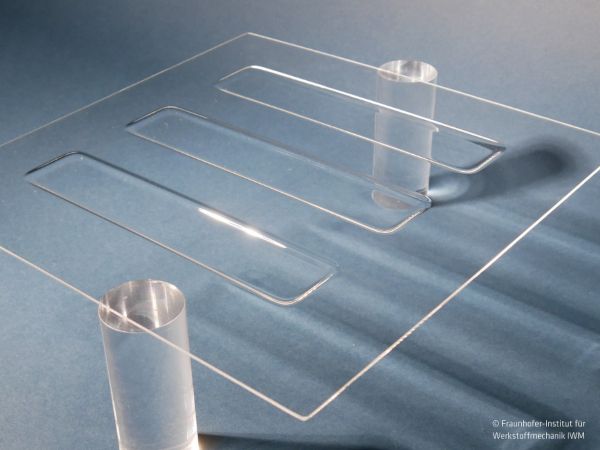

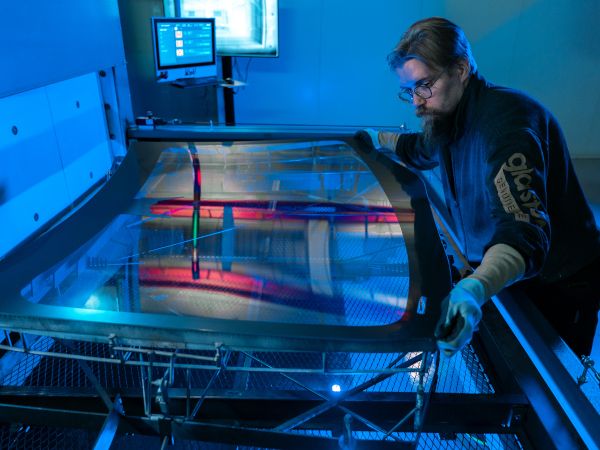

Tobias Rist of Fraunhofer IWM explains how an innovative laser process enables precise glass shaping, new structures and improved load-bearing performance for architecture and industry.

A smart solution for lighter, slimmer, and more efficient insulated glass units.

Glaston supports the more demanding automotive glass market with advanced processing technologies and consistently superior optics.

The SplitFin is a vertical processing line for flat glass with two processing towers: EPS-B for edge processing and MRX-B for internal processing.

As customer expectations for energy efficiency and glazing performance continue to rise, SafeGuard Glazing Supplies has reinforced its commitment to quality with the Sparklike Laser Portable™ 2.2.

CMS aura is the vertical dry seaming machine designed for those seeking efficiency, simplicity, and savings in the glass processing workflow.

Discover how the new Glaston TPS® PRO technology sets a new benchmark in insulating glass manufacturing.

A forward-looking collaboration between NBS and Forel shows how automation and large-format glass production are redefining the future of industrial glass manufacturing in Japan.