Others also read

Viprotron is pleased to announce its participation in GPD 2025, taking place from June 10 to 12 in Tampere, Finland. Visitors can find Viprotron at Stand 11 in the Nokia Arena.

Once again, Pujol Group has shine at China Glass 2025, reaffirming its international leader status and reinforcing its strategic position in the Asian market.

China Glass 2025 highlighted Glaston’s leadership in energy-efficient and automated glass processing technologies, perfectly aligned with China's evolving industry standards.

Pujol Group brings its latest glass innovations to Glass-Tech Poland, June 3–5, at booth B3 42B.

In this video, Tero Toivanen at Finn Lamex, Finland, is sharing his and his team's experiences working with the Glaston ScreenMax glass bending furnace for windshields.

The cooperation between the GPD and glasstec creates new synergies for the international glass industry. In an interview, Glaston explains how both formats benefit from each other - and what added value this means for the industry.

The Board of Directors of Glaston Corporation has today appointed Miika Äppelqvist as the new President and CEO of Glaston Corporation as of 1 June 2025.

Viprotron is heading to Beijing for Glass China 2025 – meet the team and discover the latest in automated glass quality inspection!

On March 10, 2025, Vitro Architectural Glass achieved a significant milestone with the installation of the third and final Osprey Distortion system at its Meadville plant in Pennsylvania.

From May 26th to 29th, 2025, Pujol will participate in China Glass 2025, reaffirming its global leadership in safety glass innovation and strengthening its presence in the Asian market.

Stable development in Architectural glass equipment in an uncertain market

Satinal has confirmed its participation in the prestigious China Glass Exhibition, scheduled to take place from May 26th to 29th, 2025, at the China International Exhibition Centre in Beijing, booth 018, hall E1.

Glaston’s organizational structure with three Business Functions, Solutions & Operations, Market Areas and Service Supply & Development, came into effect on 1 January 2025.

Glaston has received technology and equipment orders from Regency Glass, a well-known producer of high-quality IGUs in the UK.

Viprotron's Defect Pointer plays a vital role in modern inspection systems, not only helping to locate defects but also protecting the health of employees.

Glaston Corporation will publish its January–March 2025 Interim Report on Tuesday May 6, 2025 at around 8.30 a.m. Finnish time.

Satinal is pleased to confirm its attendance at Glass TEXpo™ 2025, booth #623.

The glass industry is renowned for its precision work and high quality control requirements - automated quality control has become indispensable.

Discover how solutions like the Viprotron Temper Scanner 5D are transforming quality control through advanced multi-angle inspection.

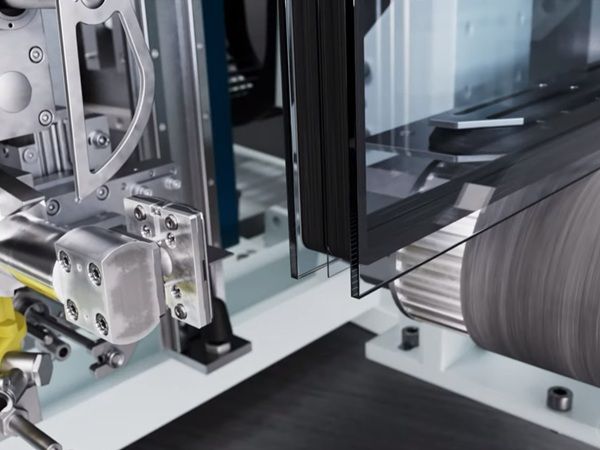

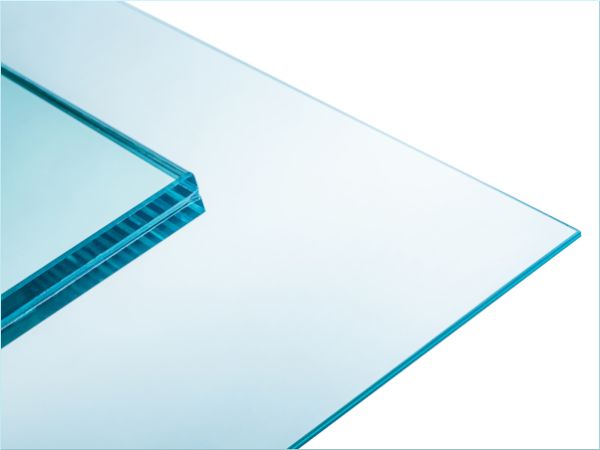

This video presents the insulating glass line Glaston ULTRA, a unique line configuration, and Glaston's patented process sequence enabling the processing of center glass as thin as 0.5 mm in triple insulating glass units.

Glaston and HEGLA will supply Glassworks with Glaston’s TPS® insulating glass line and HEGLA’s glass sorting equipment, supporting the company in increasing automation and meeting the tighter construction quality standards locally.

Glaston is taking proactive steps to adapt to ongoing market challenges and ensure long-term competitiveness.

If we check the glass market, we will find out that glass manufacturers are focusing their production on thin glass, thinner and thinner, in bigger plates too.

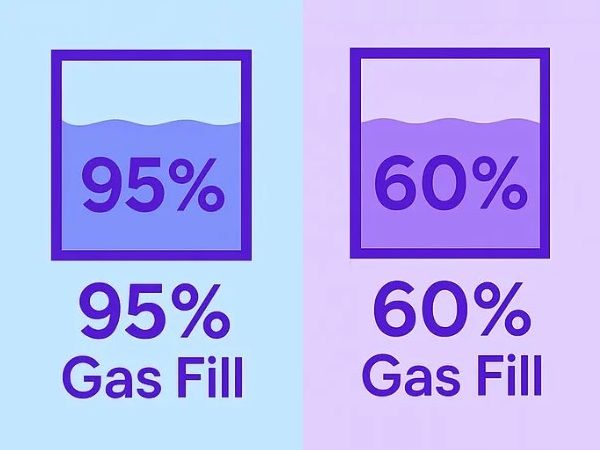

This case study involving two UK-based companies demonstrates the critical importance of precise gas measurement and proper calibration in maintaining consistent product quality.