Date: 14 June 2016

From its very start, has POLFLAM built its brand based on an unchallenged quality level. That is why it is today one of few European fire-resistant glass producers to make its product from scratch in house. While the company’s proprietary hydrogel technology, which is kept improved, allows the production of glass of unique performance parameters and exceptional durability.

Modern technology – durable quality

POLFLAM’s trademark means innovative solutions and breaking the upcoming technological barriers. The most distinct examples being: the fire-resistant bent glass, the best in Europe performance features in the EI 120 fire-resistance class, the first glass in the market of this lightness and transparency in the EI 180 class, or the large-dimensions panels, 2200×4200 mm.

Another competitive edge is the unquestionable quality of any type of the glass, with, most importantly, the guaranteed performance properties’ consistency, all the properties, not just the safety-related ones.

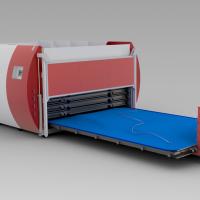

Prior to another POLFLAM® product being launched and tested at notified laboratories, all the properties of the fire-resistant glass are tested in the inhouse laboratory.

An own testing facility ensures for POLFLAM glass to be eligible to any independent verification. Nevertheless, it is the investor that is the ultimate and most independent tester of the product’s quality when testing its time length properties.

Excellence and consistency of performance properties

The fire-resistant glazed curtain walls have started a new era in architecture. Today, they have become a significant element of interior design. Hence the architects’ growing expectations. POLFLAM hydrogel technology has made the fire-resistant glass essentially lighter in weight, more transparent and larger than ever before.

POLFLAM® glass has exceptional resistance to mechanical damage, as each panel is toughened. The glass’s structure is symmetrical which eliminates the risk of wrong positioning. The edges are waterproof and blunted, the latter facilitating its installation. The glass is resistant to UV radiation which means that there is no need of using the PVB film.

All the declared parameters remain consistent in use.

Ten years passed since first POLFLAM products have been mounted. The time lap has now endorsed their quality, being the best guarantee for the product.

At the same time, the in-house laboratory never stops testing new products.

600450

600450

Add new comment