Date: 6 January 2020

The boom in the glass industry shows, that glass meets the requirements for environmental friendly packaging material, what plastic definitely not does. But as the entire industry needs to produce more efficiently and reduce CO2-emissions, the glass industry also needs to develop more environmental friendly production processes. Economic reasons are the increasing prices for CO2 allowances and the shortage of fossil fuels.

HORN can confirm this trend for the glass industry. In 2019 inquiries for low emission melting technologies have significantly increased. The requested technologies are either hybrid furnaces or even full electric furnaces based on cold top technology. The demanded melting capacities are between 150 and 300 tpd.

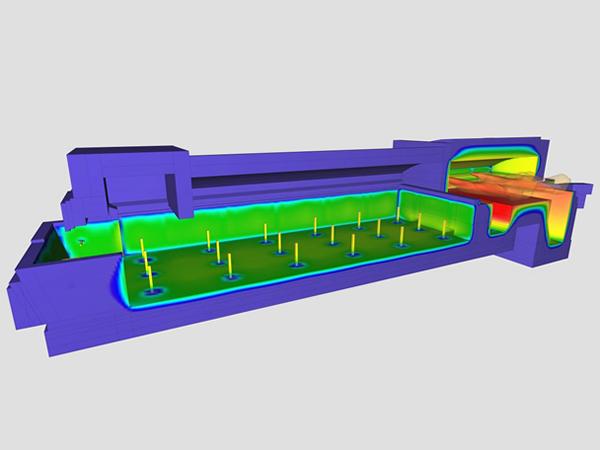

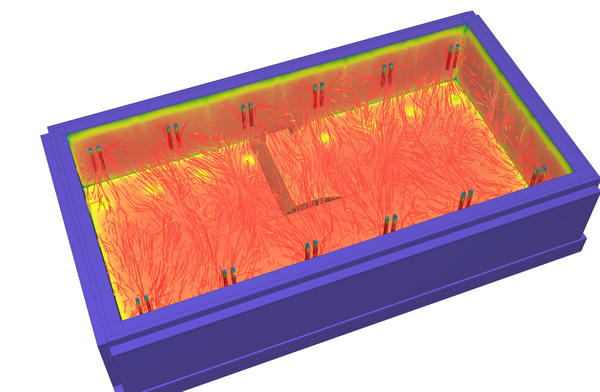

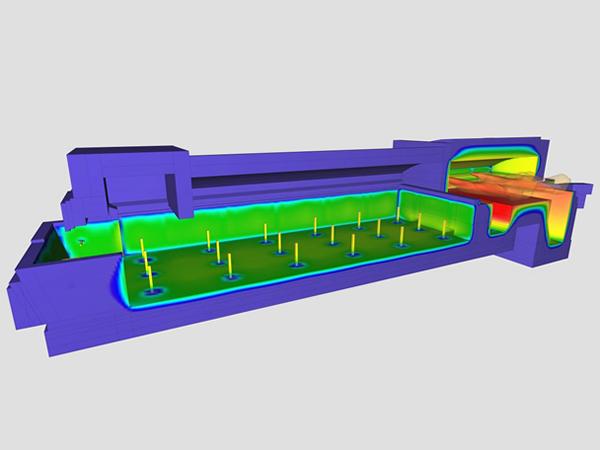

The HORN hybrid furnace is characterized by a separate batch melting tank and a refining tank, both heated with the proven HORN high power boosting system and advanced oxyfuel combustion system. The HORN full electric furnace is a rectangular-shaped, modularly constructed design as basis for flexible adaptation to the demanded melting capacity.

The heating is realized by means of the HORN top electrodes, which ensure safe operation of the furnace especially in case of metal insertion by mistake when using external cullet. In order to meet the needs of the customers, HORN further develops both technologies. Currently, HORN is able to offer hybrid furnaces for capacities up to 300 tpd and full electric furnaces of 200 tpd.

Pictures: Computer modelings of a hybrid furnace and a full electric furnace.

600450

600450

Add new comment