Date: 23 November 2015

Among its orders are truly interesting projects, for example, manufacture of the ‘petals’ of the smartflower.The smartflower is an invention and product of the Austrian business firm smartflower energy technology GmbH and is the first all-in-one autonomous energy source in the world: In the morning, the smartflower orients its large 18 m² solar module surfaces to the rising sun fully automatically and immediately begins to generate electric currents.It is fitted with a 2-axis solar tracker, so the ‘petals’ follow the sun over the course of the day. The capacity of a smartflower is about 3,400 – 6,200 kWh per year depending on the region; thus one station generates the entire average power consumption of a household in central Europe. Depending on the product, the generated electric current can either be supplied to a power net or directly stored and used locally. .jpg)

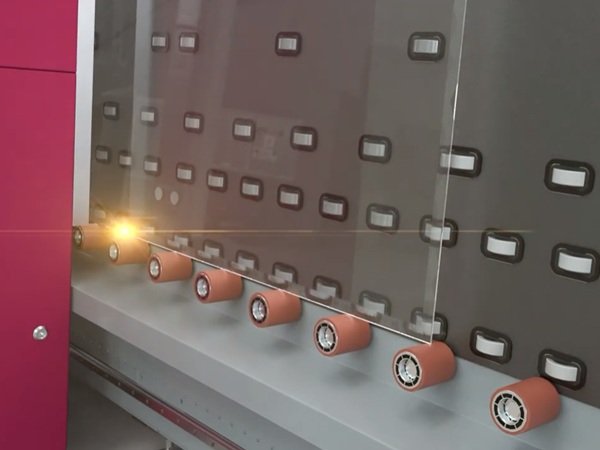

In the Glass Forum, the machine manufacturer LiSEC processes economical flat glass itself and thus builds up its operator expertise.

Image: LiSEC Austria GmbH

According to the manufacturer, the (storage) system reaches a degree of private use of up to 100 % (for comparison: a rooftop installation attains an average of only 30 %) and holds the power supply steadier than with a static rooftop installation. Smartflowers are intended for private households, but also for communes, shopping centres, companies, hotels and gastronomy..jpg)

smartflower: The first autonomous mobile energy source has a capacity of 3,400 – 6,200 kWh per year, depending on the region.

Image: smartflower energy technology GmbH

Probably the most complex flower petals in the world

Each smartflower consists of twelve petals. At first glance, one such petal does not appear to be anything spectacular. Andreas Winter, Managing Director of Glass Forum: “No manufacturer dared to produce this; we are the only glass processor in the world who accepted this job.” Each petal is 2.1 metres long and has a diameter of 1.2 metres. Winter: “The petals consist of two millimeters thin white glass. Each piece of glass is given a C-cut, after which it is tempered.” And this combination is exactly why this production technology is unparalleled. Winter continues: “We have a vertical processing machine and can then temper, with optimal batch availability; everything is highly automated.” LiSEC currently produces about 1,200 such glass petals in the Glass Forum every year. Winter is not without pride: “The manufacturing runs as if on rails: The quality has just what it takes, we meet delivery dates and rejects are virtually nil. I am happiest about those jobs where LiSEC can show what we are capable of!” .jpg)

smartflower, the all-in-one photovoltaic system which includes all the necessary components, is assembled quickly and can be easily taken along on the next move.

Image: smartflower energy technology GmbH

About LiSEC

Based in Hausmening/Amstetten, LiSEC is a global group with more than 50 years’ experience in offering innovative single and all-in-one solutions in flat glass processing and finishing. Its portfolio includes machinery, automation solutions and services. In 2014, the group generated total revenues of around 200 million euros with around 1,500 employees at over 20 sites and an export quota of more than 90 percent. LiSEC develops and manufactures glass cutting and sorting systems, single components and complete production lines for insulating and laminated glass production, glass edge processing machinery and tempering systems. With reliable technology and smart automation solutions, LiSEC sets the standard in quality and technology, contributing significantly to the success of its customers.

Add new comment