Date: 17 December 2024

Glass is an integral part of our daily lives, from the windows in our homes to the screens on our smartphones. While some types of glass, like bottles and jars, are easily recycled, others—such as medical vials and smartphone screens—often end up in landfills due to the complexity of recycling.

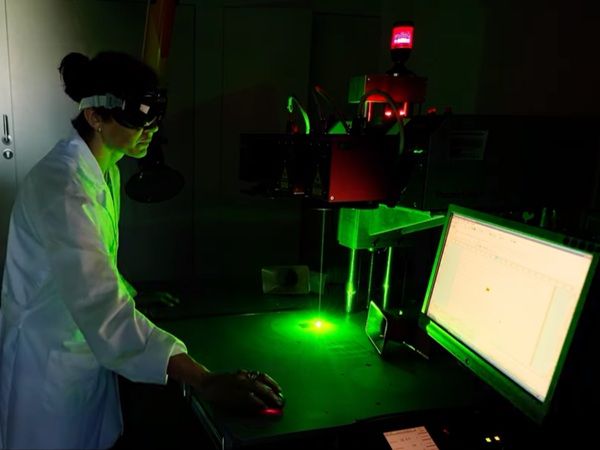

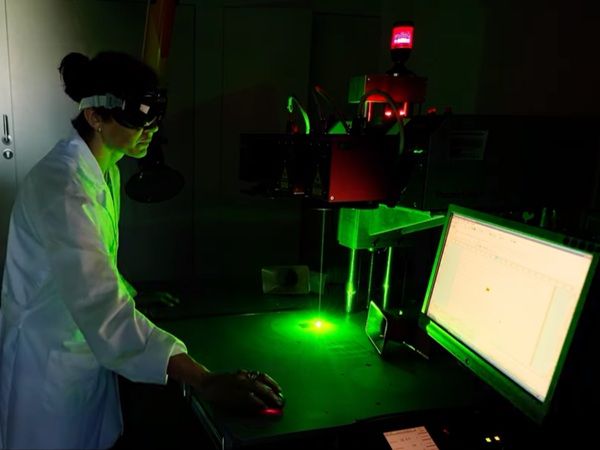

EVERGLASS aims to change the future of glass recycling with its innovative use of laser technology. The project’s mission is to create a prototype machine that uses laser technology to melt precisely and deposit glass, effectively recycling even small quantities and difficult-to-recycle types of glass. Unlike conventional recycling systems that rely on large, energy-intensive furnaces, EVERGLASS’s laser-based process provides precise control over the energy required to melt and reform glass. This technique, known as “Glass Laser Morphing”, will operate similarly to 3D printing, allowing for the creation of customised glass products without expensive moulds.

Project coordinator Juan Pou explains: “Laser technology is very good for glass recycling because it allows us to adjust the energy that we need to melt the glass and turn it into a new piece in a very controlled way.” A key advantage of this method is its flexibility in location. By placing laser morphing machines close to waste sources, transportation costs and energy usage are reduced, making it a sustainable solution.

The international and interdisciplinary research team includes eight partners from four European countries: Spain, Slovakia, France and Germany. The project began in January 2024 and will run for 36 months until December 2026.

EVERGLASS intro video

Watch scientists from the EVERGLASS team introduce the project and explain how it is improving the future of glass recycling.

600450

600450

Add new comment