Date: 15 April 2009

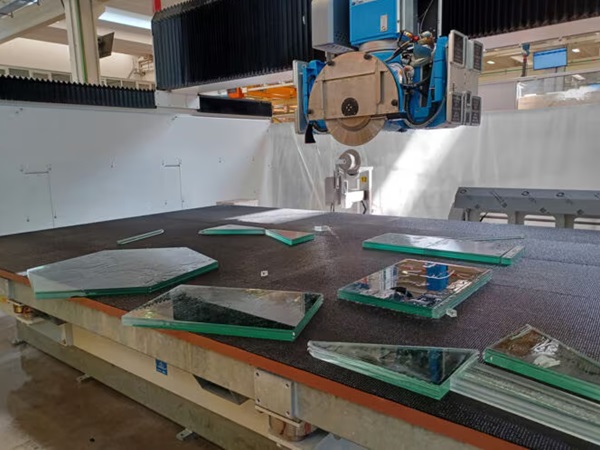

Glassman committed to develop the best glass processing equipment in favour of customers. The CNC Vertical Drilling and Milling Machine is well recognized by customers for its multifunction, precision and easy operation since it was shown to the world. Glassman sticks to innovate, breakthrough technical problem, achieves product updating and upgrading. In 2009, the new generation of CNC Vertical Drilling and Milling Machine, GM-BZX-VI, comes into international market.

-Special Humanized Design

All main processing area closed to protect, applies advanced CAD stimulate system software testing the static and dynamic moment generated during working, improved the machine’s reliability and durability by collecting and testing data, convenient to load and unload glass, took less space. The vertical structure is convenient to control the direction of force so that the processing would be much easier, also is good for the control of the tools cooling system.

-Powerful Functions

GM-BZX-VI is a working center with high technology, applies advanced NUM numerical control system from Swiss, it can complete complex work like drilling, milling and notching, arising the notches. Thanks to its powerful function and stability, Glassman GM-BZX-VI is able to beat competitors and occupied good position in international market.

-Unique Glass Transfer Method

GM-BZX-VI has special electric mechanic hand which is more reliable than other machines. Machines without mechanical hands should takes huge and complicated mechanical structure to transfer glass. It would be with high damage rate, complex repair and low precision. GM-BZX-VI adopts unique electric mechanic hand to transfer the glass to processing area. The mechanic hand advanced, precision structure, which guarantee the work would be stable, fast and accurate.

-Energy efficiency

Full automatic system makes it possible to reduce human resource, stable function means saving of cost, time and energy.

-Software

Application software for drawing, Super CAD/CAM, is developed independently by Glassman. It can work on Window XP. Glassman engineer graphics professional graphic gallery in accordance with customers’ demands, operator can choose any shape or shape combination according to different processing requirements, set some parameters. It can work automatically after system accepts parameters. The program is easy to learn and operate.

-Cost-Effective

The sales price for similar equipment from European country can achieve 140,000 to 300,000 euro, while Glassman can complete the same functions with price as low as 30% of European equipment, some functions even superior than European equipment, it deserves your investment. The flexibility of GM-BZX-VI control system can meet requirements of different product. Whole processing is completed automatically without human interference. GM-BZX-VI is particularly suited for processing structural glass (frameless shower door, glass curtain wall, glass stair protection), it would be the best choice for glass processing.

Add new comment